At their core, grip pads are adhesive, textured surfaces you stick to the bottom of your shoes. They are designed as a straightforward way to add extra traction and increase slip resistance, especially for footwear with smooth or worn-out soles.

Grip pads provide a simple, targeted solution for increasing friction on slippery shoes. However, their effectiveness is highly dependent on the shoe's material and the surfaces you walk on, making them a specific tool rather than a universal upgrade.

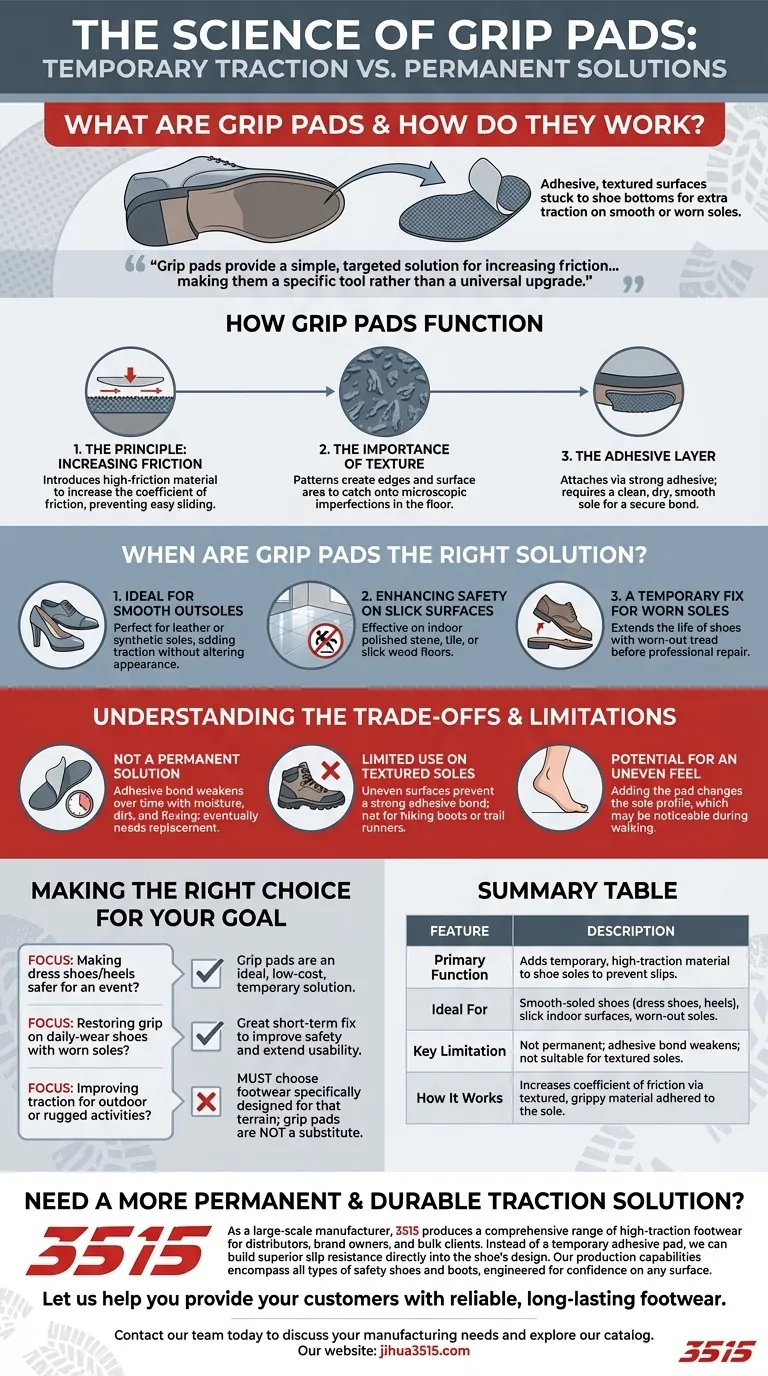

How Grip Pads Function

Grip pads work by introducing a new, high-friction material between your shoe and the ground. This simple addition fundamentally changes how your shoe interacts with a surface.

The Principle: Increasing Friction

The primary goal of a grip pad is to increase the coefficient of friction. A smooth leather or plastic sole has very little texture to "bite" into a surface, causing it to slide easily. Grip pads are made from materials with a naturally higher friction coefficient.

The Importance of Texture

These pads are not just made of a grippy material; they are almost always textured. This pattern creates more edges and surface area to catch onto microscopic imperfections in the floor, preventing slips much like the tread on a tire.

The Adhesive Layer

Grip pads attach to the shoe's outsole with a strong adhesive backing. For the pad to be effective, the shoe's sole must be clean, dry, and relatively smooth to ensure a secure, long-lasting bond.

When Are Grip Pads the Right Solution?

Grip pads excel in specific scenarios but are not suitable for every type of footwear or activity. Understanding their ideal use case is key to success.

Ideal for Smooth Outsoles

Footwear like dress shoes, high heels, or loafers often features smooth leather or synthetic soles. Grip pads are a perfect match for these, adding much-needed traction without altering the shoe's appearance significantly.

Enhancing Safety on Slick Surfaces

They are most effective on smooth indoor surfaces where slips are common, such as polished stone, tile, or slick wood floors. They provide an immediate and noticeable improvement in stability.

A Temporary Fix for Worn Soles

If the original tread on a pair of comfortable shoes has worn smooth, a grip pad can be an excellent way to extend their life and restore lost traction before committing to a more expensive professional repair.

Understanding the Trade-offs and Limitations

While useful, grip pads are a compromise and come with inherent limitations that you must consider.

Not a Permanent Solution

The adhesive bond is the weakest link. Over time, and with exposure to moisture, dirt, and constant flexing, the pad can begin to peel away from the shoe and will eventually need to be replaced.

Limited Use on Textured Soles

Grip pads are not designed for shoes that already have deep, aggressive treads, like hiking boots or trail runners. The uneven surface prevents the adhesive from forming a strong, reliable bond.

Potential for an Uneven Feel

Adding a pad, no matter how thin, changes the profile of your shoe's sole. Depending on the placement and thickness, some users may notice a slight change in how the shoe feels when walking.

Making the Right Choice for Your Goal

To decide if grip pads are right for you, match them to your specific need.

- If your primary focus is making dress shoes or heels safer for an event: Grip pads are an ideal, low-cost solution for temporary confidence on slick floors.

- If your primary focus is restoring grip on daily-wear shoes with worn-out soles: They serve as a great short-term fix to improve safety and extend the shoe's usability.

- If your primary focus is improving traction for outdoor or rugged activities: You must choose footwear specifically designed for that terrain, as grip pads are not a suitable substitute.

By understanding their specific function, you can use grip pads as a precise tool to walk with greater confidence.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | Adds temporary, high-traction material to shoe soles to prevent slips. |

| Ideal For | Smooth-soled shoes (dress shoes, heels), slick indoor surfaces, and worn-out soles. |

| Key Limitation | Not a permanent solution; adhesive bond weakens over time and is not suitable for textured soles. |

| How It Works | Increases the coefficient of friction via a textured, grippy material adhered to the sole. |

Need a More Permanent and Durable Traction Solution?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-traction footwear for distributors, brand owners, and bulk clients. Instead of a temporary adhesive pad, we can build superior slip resistance directly into the shoe's design. Our production capabilities encompass all types of safety shoes and boots, engineered for confidence on any surface.

Let us help you provide your customers with reliable, long-lasting footwear.

Contact our team today to discuss your manufacturing needs and explore our catalog.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Why is wearing slip-resistant shoes important in the workplace? Prevent Costly Falls & Injuries

- Why are standardized anti-slip work shoes required in biomechanical research? Ensuring Data Accuracy in Slip Studies

- How do specialized traction patterns in non-slip shoes work? The Science of Water Displacement

- What is the significance of tread patterns in non-slip shoes? Prevent Slips with Expert Sole Design

- Which industries particularly benefit from slip resistant footwear? Protect Your Workforce from Costly Falls

- Do slip-resistant shoes work on all types of spills? The Truth About Matching Shoes to Hazards

- How can you test the arch support of slip-resistant shoes? The Simple Bend Test for All-Day Comfort

- Does hairspray make shoes slip-resistant? Avoid This Dangerous DIY Myth