Beyond the obvious spill, the most common factors creating hazardous slippery floors in the workplace are surface contaminants like oil and grease, water from cleaning processes, and a hidden environmental condition known as "sweating slab syndrome." These issues create a constant risk, particularly in high-traffic service and industrial environments.

The root cause of a slippery floor is not just the substance on it, but understanding how it got there. Identifying whether the hazard is from operational spills, maintenance activities, or the building's infrastructure itself is the key to effective and permanent prevention.

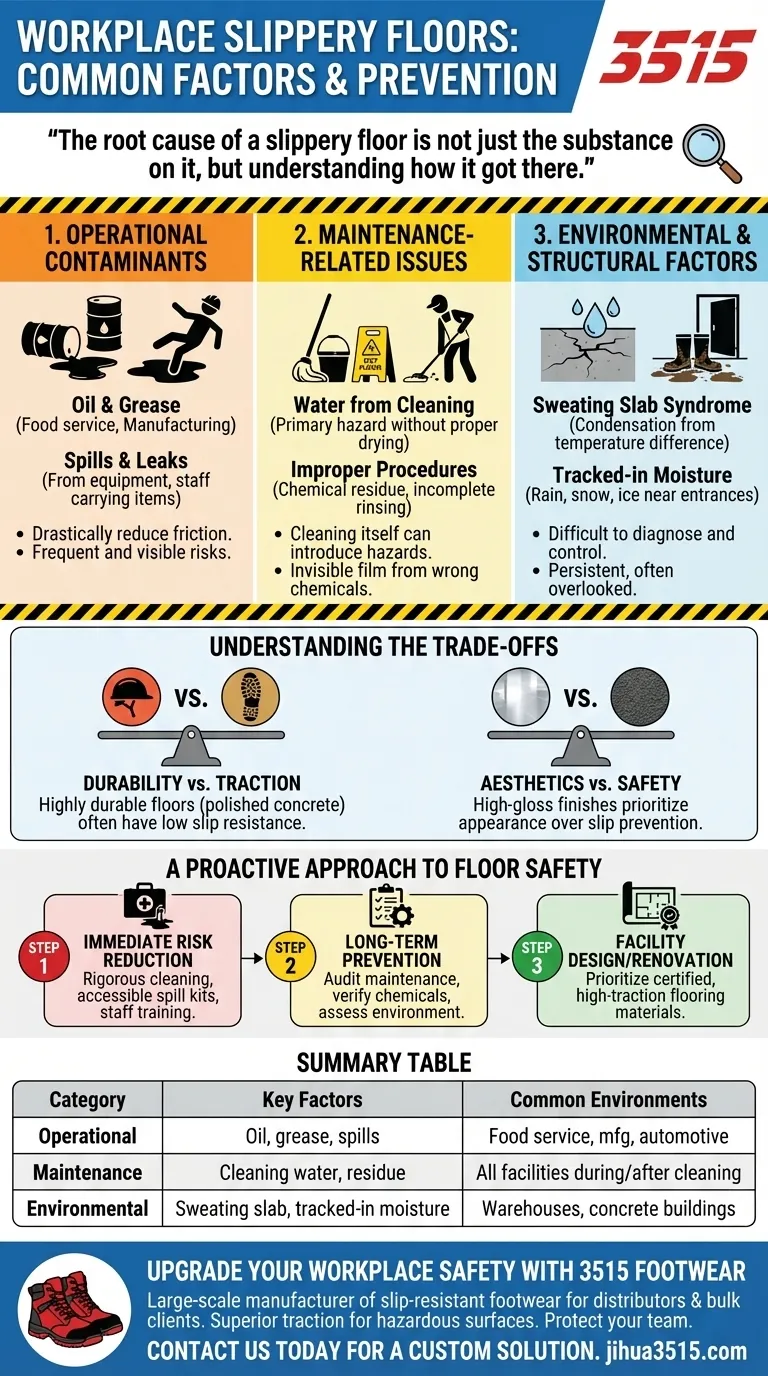

The Sources of Slip Hazards

To properly address slippery floors, we must categorize the sources of the problem. Most incidents trace back to one of three distinct areas: daily operations, maintenance procedures, or environmental conditions.

Category 1: Operational Contaminants

These are substances introduced to the floor during the course of normal work activities. They represent the most frequent and visible risks.

Oil and Grease These are among the most dangerous contaminants because they drastically reduce the friction between a shoe and the floor surface. They are especially prevalent in food service environments, like those for baristas and servers, as well as in manufacturing or automotive repair facilities.

Spills and Leaks Even small amounts of liquid from leaking equipment or customer spills can create a significant hazard. The risk is compounded in areas where staff are often carrying items, which can obstruct their view of the floor.

Category 2: Maintenance-Related Issues

Ironically, the very act of cleaning and maintaining a floor can introduce its own set of slip hazards if not performed correctly.

Water from Floor Maintenance Mopping or scrubbing floors introduces water, which is a primary slip hazard. Without proper signage, barricades, and adequate drying time, a recently cleaned floor is one of the most dangerous areas in any facility.

Improper Cleaning Procedures Using the wrong type of cleaning chemical or an incorrect dilution can leave behind a slippery residue. Similarly, failing to fully rinse away detergents can create a slick, invisible film that becomes extremely hazardous when exposed to even a small amount of moisture.

Category 3: Environmental and Structural Factors

Some hazards are not caused by spills or cleaning but by the building and its environment. These are often the most difficult to diagnose and control.

Sweating Slab Syndrome This phenomenon occurs when a concrete floor slab's temperature is cooler than the dew point of the ambient air. This temperature difference causes moisture to condense directly onto the floor surface, making it damp and slippery without any leak or spill.

Tracked-in Moisture Rain, snow, or ice can be tracked into a building on employees' and visitors' shoes. This water accumulates near entrances, creating a persistent and often overlooked slip hazard.

Understanding the Trade-offs

Choosing and maintaining a flooring system involves balancing competing priorities. What makes a floor desirable for one reason can make it hazardous for another.

Durability vs. Traction

Highly durable and non-porous floors, like polished concrete or epoxy coatings, are popular for their longevity and ease of cleaning. However, their smooth, hard surfaces can offer very low slip resistance, especially when wet or contaminated.

Aesthetics vs. Safety

A high-gloss, mirror-like finish is often a key aesthetic goal for retail and corporate spaces. Unfortunately, the processes used to achieve this shine often result in a smoother, less textured surface with a lower coefficient of friction, prioritizing appearance over slip prevention.

A Proactive Approach to Floor Safety

Your strategy for preventing slips and falls should be determined by your specific environment and goals.

- If your primary focus is immediate risk reduction: Implement rigorous daily cleaning protocols, ensure spill kits are accessible, and train all staff on immediate spill management.

- If your primary focus is long-term prevention: Audit your floor maintenance procedures, verify the use of correct cleaning agents, and assess your facility for environmental factors like sweating slab syndrome.

- If your primary focus is facility design or renovation: Prioritize flooring materials that offer a certified, high coefficient of friction even when wet, balancing durability with proven safety.

Ultimately, creating a safe walking surface is a foundational responsibility, built by understanding the complete life cycle of your floors.

Summary Table:

| Category | Key Factors | Common Environments |

|---|---|---|

| Operational Contaminants | Oil, grease, liquid spills | Food service, manufacturing, automotive |

| Maintenance-Related Issues | Water from cleaning, improper chemicals | All facilities during/after cleaning |

| Environmental Factors | Sweating slab syndrome, tracked-in moisture | Warehouses, buildings with concrete slabs |

Upgrade your workplace safety with the right footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes designed to provide superior traction on hazardous surfaces. Protect your team and reduce slip-and-fall risks—contact us today for a custom solution!

Visual Guide

Related Products

- Durable Moc Toe Wedge Sole Work Boots for Wholesale and Private Label

- Durable Leather Moc Toe Work Boots for Wholesale & Custom Manufacturing

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the important characteristics for work boot soles? Match the Sole to Your Job for Safety & Comfort

- Why is it important to take care of your feet? Secure Your Mobility and Overall Health

- Why are slip-on moc toe shoes a practical choice for formal events? Unlock Effortless Style & Comfort

- How do wedge sole work boots prevent slips and falls? Maximize Grip on Concrete & Hard Floors

- What weather-related protections do work boots offer? Essential Guide to Dry, Warm, & Safe Feet