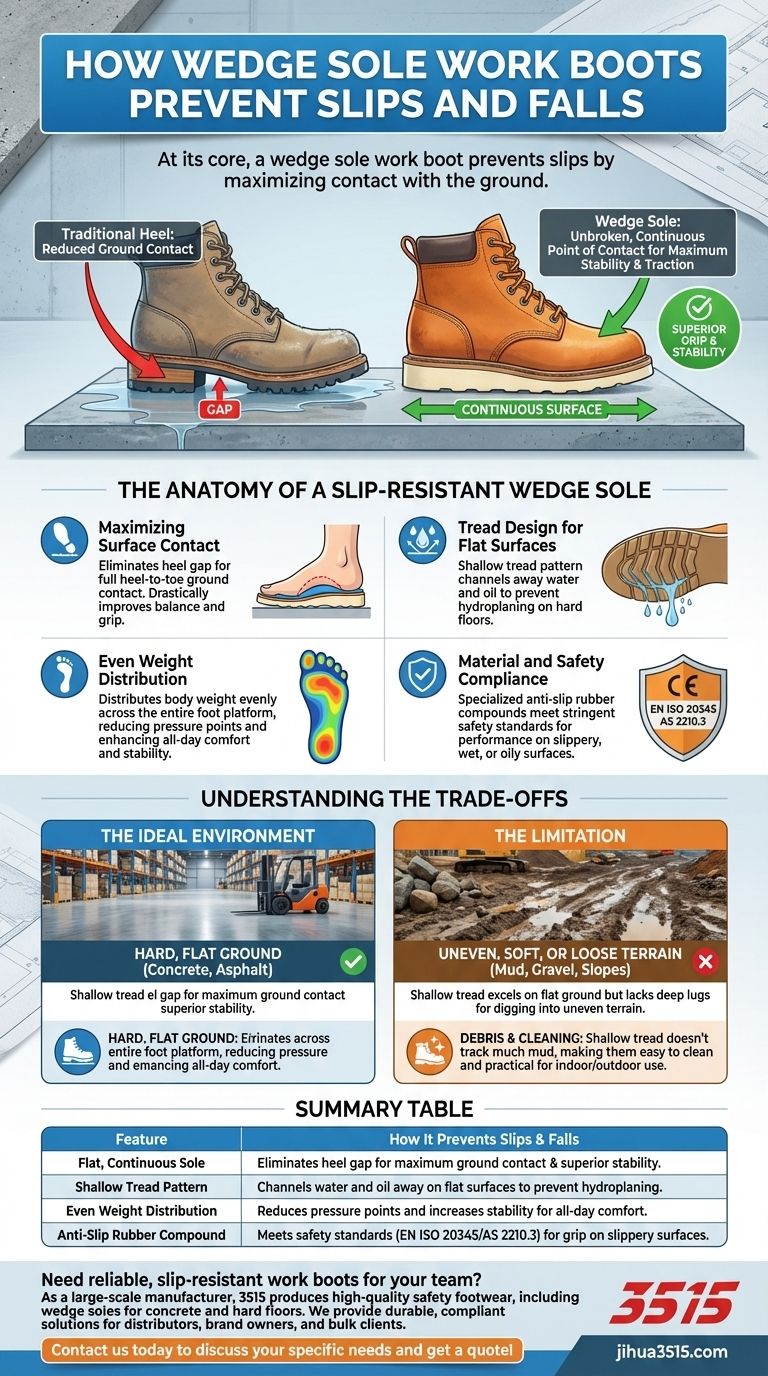

At its core, a wedge sole work boot prevents slips by maximizing contact with the ground. Unlike a traditional heeled boot, its flat-bottomed outsole is a single, solid piece that runs the entire length of the boot. This continuous surface area provides superior grip and stability, especially on hard, flat surfaces like concrete or asphalt.

The primary advantage of a wedge sole is not complex tread patterns, but its fundamental design: providing an unbroken, continuous point of contact between you and the walking surface for maximum stability and traction.

The Anatomy of a Slip-Resistant Wedge Sole

To understand why wedge soles are effective, you must look at how their specific design features work together to keep you upright and stable in demanding environments.

Maximizing Surface Contact

The most critical feature of a wedge sole is its uninterrupted surface. A traditional boot has a heel, creating a gap where the sole does not touch the ground.

A wedge sole eliminates this gap. This design ensures your entire foot, from heel to toe, maintains contact with the ground at all times, drastically improving your balance and grip.

Tread Design for Flat Surfaces

Wedge soles typically have a shallower tread pattern compared to deep-lugged logger or hiking boots.

This design is highly effective at channeling away liquids like water and oil on flat ground. It prevents fluids from getting trapped under the boot, which is a common cause of hydroplaning and slipping.

Even Weight Distribution

The flat, continuous nature of the sole distributes your body weight evenly across the entire platform of your foot.

This even distribution not only enhances all-day comfort by reducing pressure points but also contributes to a more stable and secure footing, reducing the likelihood of a misstep.

Material and Safety Compliance

Modern wedge soles are made from specialized anti-slip rubber compounds engineered for grip.

To be sold as safety footwear, these boots must meet stringent standards, such as EN ISO 20345 or AS 2210.3, which certify their performance on slippery, wet, or oily surfaces.

Understanding the Trade-offs

While highly effective, the wedge sole is a specialized tool. Its design offers clear benefits in certain conditions but comes with limitations in others.

The Ideal Environment: Hard, Flat Ground

Wedge soles provide their greatest advantage in environments with hard, flat surfaces.

Think of warehouse floors, manufacturing plants, garages, and paved construction sites. In these settings, the maximized surface contact provides unmatched slip resistance.

The Limitation: Uneven and Soft Terrain

The same shallow tread that excels on flat ground becomes a liability on uneven, soft, or loose terrain.

On mud, gravel, or steep inclines, a wedge sole lacks the deep, aggressive lugs needed to dig in and provide grip. A traditional heeled boot is superior in these conditions.

Debris and Cleaning

A secondary benefit of the shallow tread is that it doesn't track much mud or debris. This makes wedge soles easy to clean and a practical choice for workers who move between outdoor and indoor environments.

Making the Right Choice for Your Work

Selecting the right sole is about matching the boot's design to your primary work environment.

- If your primary focus is safety on concrete or asphalt: The maximum surface contact of a wedge sole offers superior slip resistance and stability for these environments.

- If your primary focus is all-day comfort on hard floors: The even weight distribution of a wedge sole is a significant advantage for reducing foot fatigue.

- If your primary focus is traction on mud, gravel, or hills: A traditional heeled boot with deep, aggressive lugs will provide the necessary grip that a wedge sole cannot.

Ultimately, choosing the right work boot means understanding that the sole is the most critical tool for keeping you safe and stable on your feet.

Summary Table:

| Feature | How It Prevents Slips & Falls |

|---|---|

| Flat, Continuous Sole | Eliminates heel gap for maximum ground contact and superior stability. |

| Shallow Tread Pattern | Channels water and oil away on flat surfaces to prevent hydroplaning. |

| Even Weight Distribution | Reduces pressure points and increases stability for all-day comfort. |

| Anti-Slip Rubber Compound | Meets safety standards (EN ISO 20345/AS 2210.3) for grip on slippery surfaces. |

Need reliable, slip-resistant work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety footwear, including specialized wedge sole boots designed for maximum grip on concrete and hard floors. We provide durable, compliant footwear solutions for distributors, brand owners, and bulk clients.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are moc toe boots inspired by? A Deep Dive into Rugged Heritage & Style

- Why do fire boots have a heel? The Critical Safety Feature for Firefighters

- Why are cowboy boots a practical footwear choice? Discover Their Durable, Purpose-Built Design

- How can you extend the lifespan of work shoes? A Systematic Guide to Doubling Your Footwear's Life

- Who commonly wears harness boots? From Motorcycle Riders to Fashion Icons

- How can you create a Minimalist Modern Style with moc toe boots? Elevate Your Wardrobe

- What are the conductive properties requirements in ASTM standards? A Guide to CD vs. SD Footwear

- When are High Leg boots recommended? For Maximum Ankle Support on Hazardous Terrain