First, I'm going to dig into the user's needs. They want "additional tips," but what's the real goal? Safety, comfort, and a smart purchase that lasts. They are moving from a basic understanding of non-slip shoes to needing very specific information about the right features for their job. I need to make them an expert.

I'm structuring the article with an impactful opening, immediately addressing the key "additional tips," like third-party certifications, employer recommendations, and fit. Then, I'll emphasize the core takeaway: it's about matching the shoe to the work environment and the person's feet.

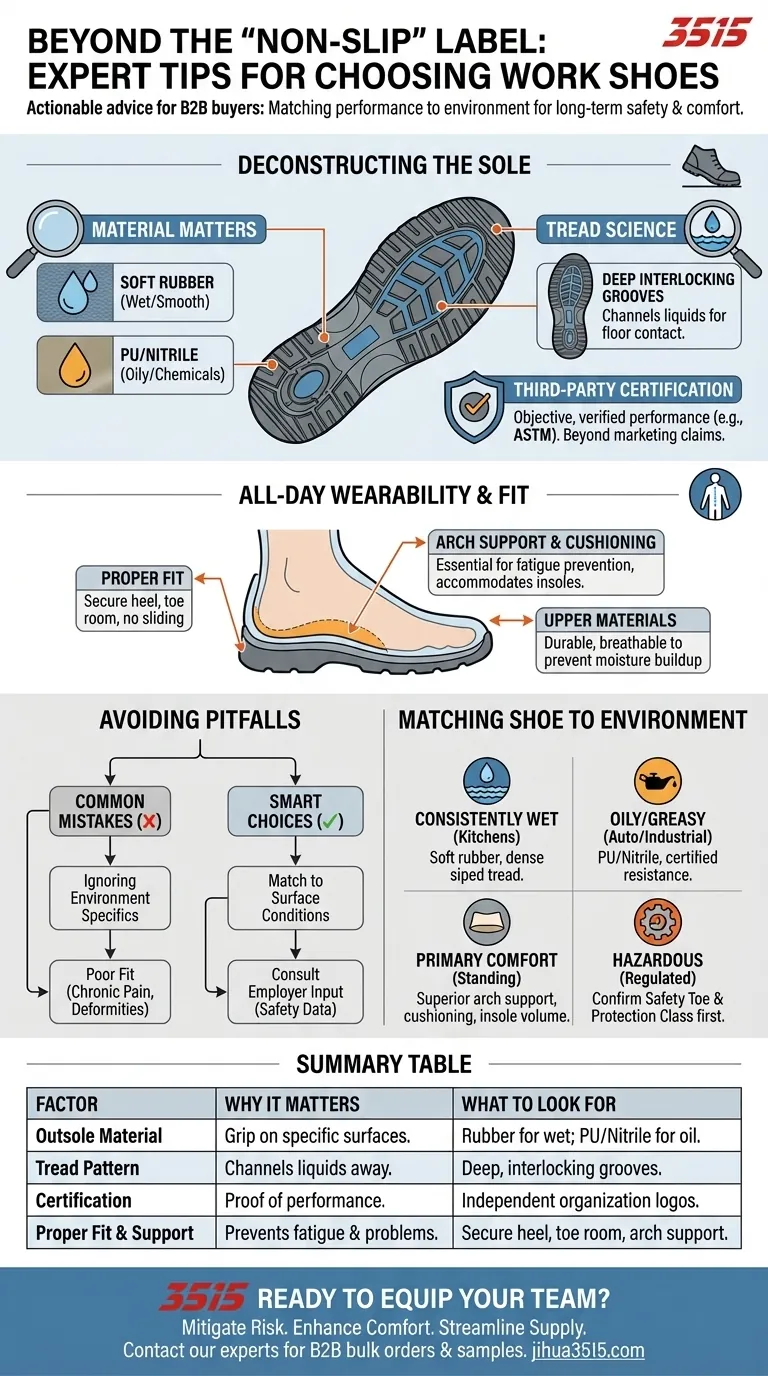

The main body will tackle the technical details. I'll deconstruct the "non-slip" outsole, explaining the importance of the material (rubber vs. PU), and the science behind tread patterns, especially the importance of interlocking patterns. I'll stress the value of third-party certification.

The second part focuses on all-day wearability. I will stress the importance of proper fit and good arch support, and I'll touch on the role of upper materials.

Then, there'll be a section on trade-offs. Not all "non-slip" shoes are equal, and there's a real cost to a poor fit, both in comfort and in safety. I will reiterate that they should speak to their employer.

The concluding section will be all about actionable advice, in a bulleted format for easy reference. I'll give specific recommendations based on the work environment, whether it's wet, oily, or primarily about comfort.

Throughout, I'll synthesize the information from the provided references. I'll translate the technical details into plain language, explaining why things matter (like "deep tread" creating liquid channels). My tone will be calm, objective, and authoritative. I will ensure the final piece is both comprehensive and practical, empowering the user to make a truly informed decision. Ultimately, this isn't just about shoes; it's about investing in daily safety and long-term well-being. Beyond the "non-slip" label, the most crucial steps in selecting work shoes involve verifying their performance through third-party certifications, understanding the specific design of the outsole, and ensuring a precise fit for all-day comfort and stability. Your employer can also be a valuable resource, often providing recommendations based on the specific hazards of your workplace.

The goal is not just to find a shoe marketed as "non-slip," but to match the specific outsole material, tread design, and overall construction to your unique work environment and personal anatomy. This holistic approach is the true key to workplace safety and long-term foot health.

Deconstructing the "Non-Slip" Outsole

The effectiveness of a non-slip shoe is determined by the engineering of its outsole. Understanding these components allows you to look past marketing claims and assess the shoe's true performance potential.

Material Matters: Rubber and PU

The material of the outsole is your first point of contact with the ground. Soft rubber is a common choice, offering excellent grip on wet or smooth surfaces. Another popular option is a polyurethane (PU) sole, which provides good traction and is often more durable and resistant to chemicals.

The Science of Tread Patterns

A flat sole is a hazardous sole. The pattern of the tread is designed to increase the surface area and channel away liquids that cause slips. Look for deep tread grooves or an interlocked tread pattern. These designs create pathways for water, oil, and other fluids to disperse, allowing the sole to maintain direct contact with the floor.

Look for Third-Party Certification

The most reliable way to verify a shoe's slip resistance is to look for independent certification. A shoe that has been tested and certified by a third-party organization meets objective, standardized criteria for performance, giving you confidence that goes beyond the manufacturer's own claims.

Beyond the Sole: Prioritizing All-Day Wearability

An effective work shoe must be safe, but it must also be comfortable enough to wear for an entire shift. Discomfort leads to distraction and fatigue, which can increase the risk of accidents.

The Critical Importance of Proper Fit

A shoe that is too large allows your foot to slide internally, causing instability. A shoe that is too small can cause pain, blisters, and long-term foot problems. Always try on shoes before purchasing, and ensure there is enough room for your toes without excessive movement in the heel.

Assessing Arch Support and Cushioning

Many work shoes offer minimal arch support out of the box. If you spend long hours on your feet, proper arch support and cushioning are non-negotiable for preventing fatigue and conditions like plantar fasciitis. Factor in whether the shoe has enough room to accommodate a supportive insole or custom orthotic if needed.

The Role of Upper Materials

The upper part of the shoe contributes to both durability and comfort. Look for durable materials that can withstand the wear and tear of your job. Breathability is also key, as it helps prevent sweat and moisture buildup, keeping your feet dry and reducing the risk of fungal infections.

Understanding the Trade-offs and Pitfalls

Choosing the right shoe involves balancing competing factors and avoiding common mistakes that can compromise your safety and comfort.

Not All "Non-Slip" Shoes Are Equal

A shoe designed for a wet kitchen floor may not perform well on an oily auto shop floor. The term "non-slip" is context-dependent. Always match the shoe's specified capabilities to the exact surface conditions you face daily.

The Hidden Cost of a Poor Fit

The consequences of an improper fit go beyond temporary discomfort. Over time, poorly fitting footwear can contribute to chronic pain, bunions, and other foot deformities, ultimately impacting your ability to work safely and effectively.

Forgetting Your Employer's Input

Your employer or safety manager has a vested interest in preventing workplace accidents. They often have specific footwear requirements or brand recommendations based on historical incident data and the unique hazards present in your work environment. Always consult them before making a final decision.

Making the Right Choice for Your Environment

Your specific job dictates the right features. Use these guidelines to narrow your focus and select the ideal shoe for your needs.

- If you work on consistently wet surfaces (e.g., kitchens, food processing): Prioritize soft rubber outsoles with dense, siped tread patterns designed to channel water away effectively.

- If you work on oily or greasy surfaces (e.g., auto shops, industrial settings): Focus on shoes with certified slip-resistance and a PU or nitrile rubber sole that resists chemical breakdown.

- If your primary concern is all-day comfort while standing: Look for superior built-in arch support and cushioning, and ensure there is enough volume for custom orthotics.

- If you work in a regulated or hazardous environment: Always start by confirming the required safety toe type and protection class (e.g., ASTM ratings) before considering any other feature.

Investing in the right footwear is a direct investment in your daily safety and long-term well-being.

Summary Table:

| Key Selection Factor | Why It Matters | What to Look For |

|---|---|---|

| Outsole Material | Determines grip on specific surfaces (wet vs. oily). | Soft rubber for wet floors; PU/nitrile for oily environments. |

| Tread Pattern | Channels liquids away to maintain floor contact. | Deep, interlocking grooves and sipes (slits) for superior slip resistance. |

| Third-Party Certification | Provides objective proof of performance beyond marketing claims. | Look for logos from independent testing organizations. |

| Proper Fit & Support | Prevents fatigue, instability, and long-term foot problems. | Secure heel, room for toes, and adequate arch support/cushioning. |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip work shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, engineered with the precise outsole materials, tread patterns, and comfort features detailed in this guide.

We help you:

- Mitigate Workplace Risks: Provide your team with certified, high-traction footwear tailored to your specific environmental hazards.

- Enhance Worker Comfort & Productivity: Offer durable boots and shoes with excellent support for all-day wear, reducing fatigue.

- Streamline Your Supply Chain: Benefit from our high-volume manufacturing, consistent quality, and reliable delivery for all your bulk orders.

Let's discuss your specific needs. Whether you're a distributor, brand owner, or a large enterprise, we can provide the perfect footwear solution.

Contact our experts today for a consultation and to request samples.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites