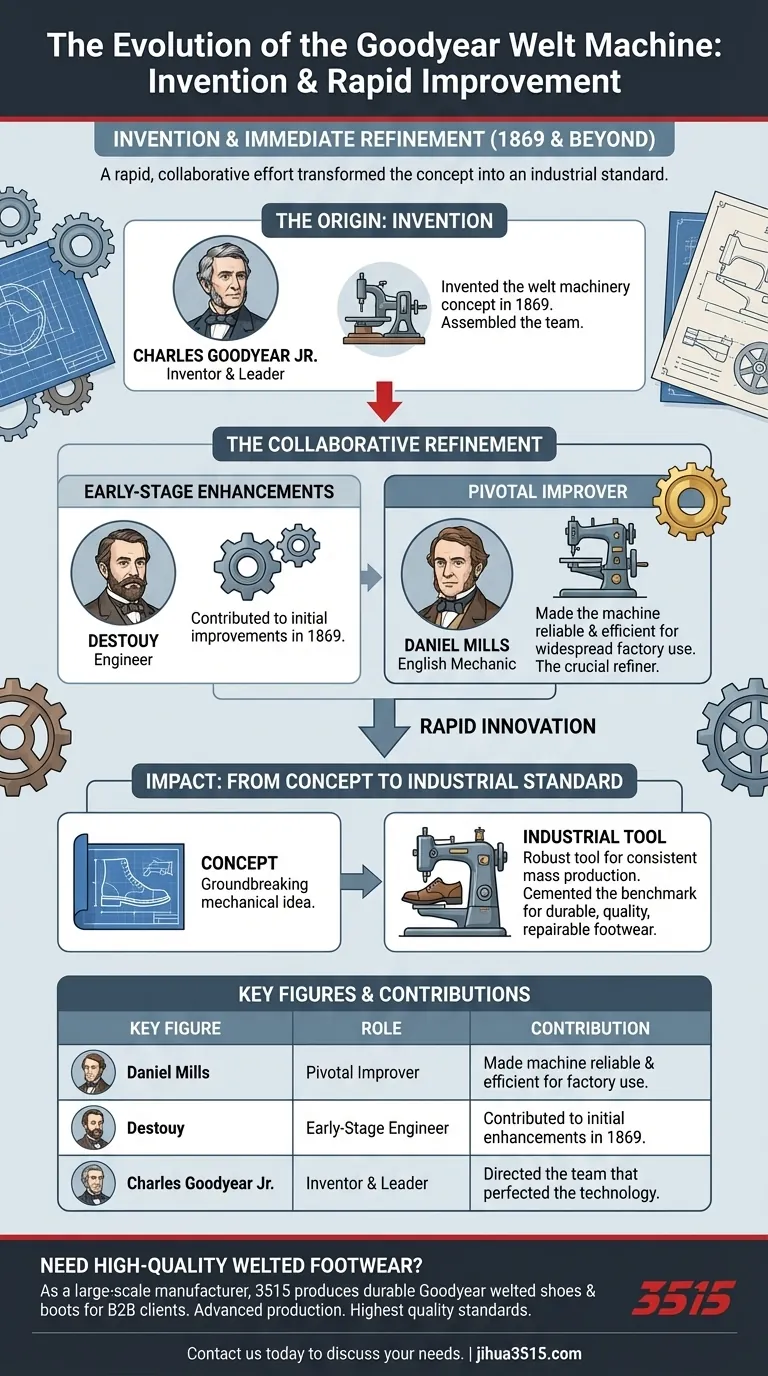

Immediately following its invention, the Goodyear welt machine was significantly improved in 1869 and the years after by two key individuals in the employ of the inventor, Charles Goodyear Jr. These improvements were driven by an engineer named Destouy and, most critically, by an English mechanic named Daniel Mills.

The evolution of the Goodyear welt machine was not a single event but a rapid, collaborative refinement. While Charles Goodyear Jr. invented the machinery, it was the immediate and crucial improvements by his employee Daniel Mills that perfected it for industrial use.

The Key Figures Behind the Refinement

To understand how the machine evolved, we must look at the specific roles of the people involved. The process was a clear example of an inventor leading a team of specialists to perfect a new technology.

Charles Goodyear Jr.: The Inventor and Leader

Charles Goodyear Jr., son of the famous vulcanized rubber inventor Charles Goodyear, is credited with inventing the machinery for the welt process in 1869. His primary role was that of the innovator and the director who assembled the talent needed to turn his concept into a commercial reality.

Destouy's Contributions

One of the engineers employed by Goodyear Jr. was a man named Destouy. He was one of the first individuals tasked with improving upon the initial machine design in 1869, contributing to its early-stage enhancements.

Daniel Mills: The Pivotal Improver

The most significant contributions came from Daniel Mills, an English mechanic also working for Goodyear Jr. The historical record emphasizes his work as being more important, suggesting his refinements were pivotal in making the machine reliable, efficient, and ready for widespread factory adoption.

The Impact of Rapid Innovation

The timeline of the Goodyear welt machine is condensed, with invention and improvement happening almost simultaneously. This highlights the intense focus on making the technology viable from day one.

From Concept to Industrial Tool

The initial invention provided the mechanical concept. However, the subsequent improvements by Mills and Destouy were what transformed it from a groundbreaking idea into a robust industrial tool capable of consistent mass production.

Setting the Standard for Footwear

These early refinements were so effective that they cemented the Goodyear welting process as the benchmark for durable, high-quality, and repairable footwear. The core principles established by these improvements still define the process today.

Key Takeaways on the Goodyear Welt's Evolution

Understanding the history requires appreciating the different contributions that led to its success.

- If your primary focus is the inventor: Credit Charles Goodyear Jr. for creating the machinery in 1869.

- If your primary focus is the crucial improvement: Acknowledge Daniel Mills as the key mechanic whose work perfected the machine for industrial use.

- If your primary focus is the overall team: Recognize that the success was a collaborative effort led by Goodyear Jr. and executed by engineers like Destouy and Mills.

This focused, collaborative effort is why the Goodyear welt quickly became the enduring standard for quality shoemaking.

Summary Table:

| Key Figure | Role in Improvement | Contribution |

|---|---|---|

| Daniel Mills | Pivotal Improver | Made the machine reliable & efficient for factory use |

| Destouy | Early-Stage Engineer | Contributed to initial enhancements in 1869 |

| Charles Goodyear Jr. | Inventor & Leader | Directed the team that perfected the technology |

Need High-Quality Welted Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure the highest standards of quality and consistency.

Contact us today to discuss your footwear needs and leverage our manufacturing expertise for your brand.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

People Also Ask

- What makes work boots durable? The 3 Key Factors for Long-Lasting Footwear

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- What are the advantages and disadvantages of leather as a shoe material? Unlock Durability, Comfort & Style

- How can the flexibility of leather work boots be maximized? Achieve Lasting Comfort & Performance

- What are the best practices for storing leather work boots? Preserve Your Investment for Years