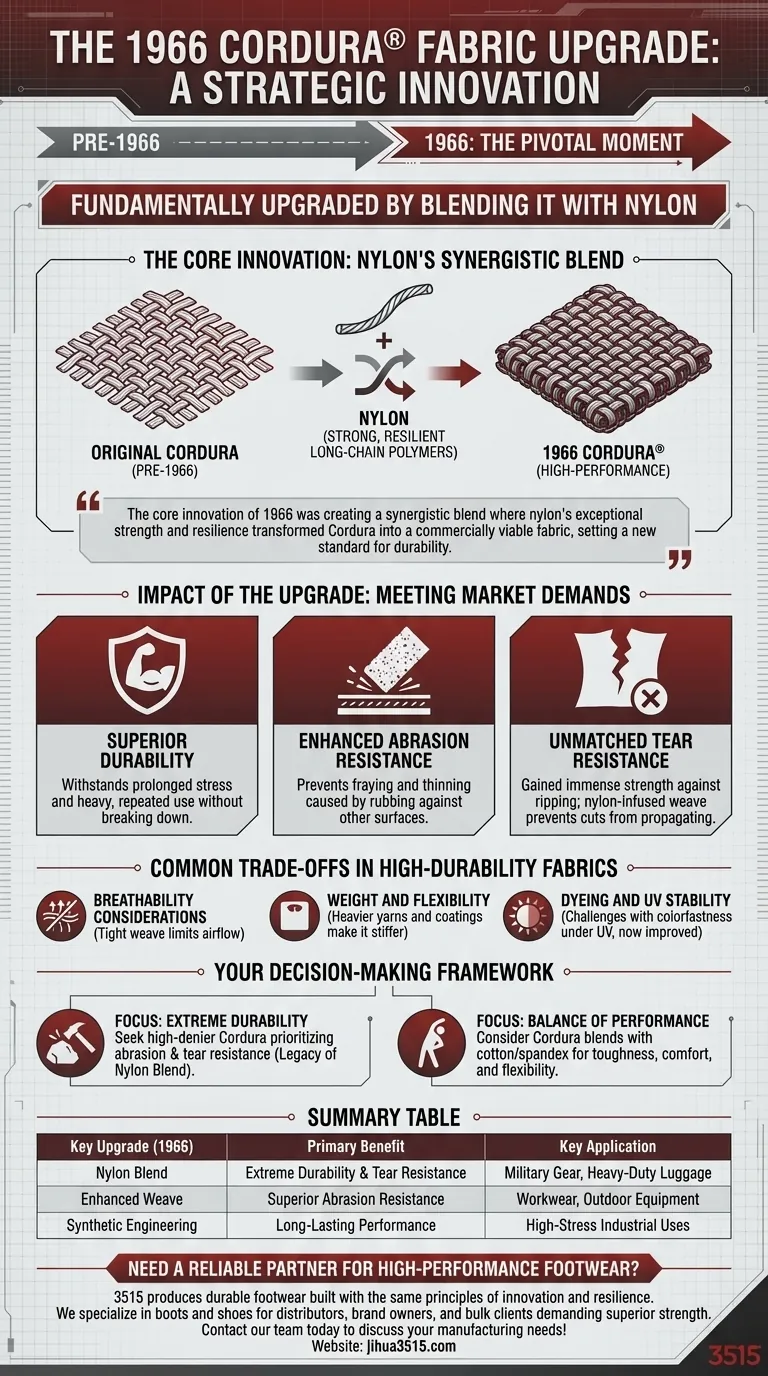

In 1966, Cordura fabric was fundamentally upgraded by blending it with nylon. This strategic innovation dramatically enhanced its strength, creating a new version of the fabric with significantly improved durability, tear resistance, and abrasion resistance that could meet growing market demands for high-performance textiles.

The core innovation of 1966 was creating a synergistic blend where nylon's exceptional strength and resilience transformed Cordura into a commercially viable fabric, setting a new standard for durability.

The Technical Leap of 1966

The 1966 upgrade was not a minor tweak; it was a complete re-engineering of the material that established Cordura's modern reputation. The key was leveraging a new, powerful synthetic fiber.

The Key Innovation: Introducing Nylon

The most critical change was the introduction of nylon into the fabric's composition. This specific blend created a material far superior to its predecessors.

Researchers effectively combined the properties of two different materials to create a composite with enhanced characteristics.

Why Nylon Was the Missing Piece

Nylon brought exceptional durability and resilience to the table. Its long-chain polymers are incredibly strong and resistant to damage from friction, pulling, and tearing.

This blend directly addressed the primary weaknesses of earlier fabrics, transforming Cordura into a material suitable for demanding applications.

Meeting a New Market Demand

By the mid-1960s, there was a clear commercial need for tougher, longer-lasting fabrics for everything from luggage to military gear.

The new nylon-blended Cordura perfectly met this demand, leading to its rapid adoption and increased commercial value. It solved a real-world problem for manufacturers who needed a more reliable textile.

Understanding the Impact of the Upgrade

The specific performance benefits of the nylon blend were immediate and significant, defining the characteristics that the Cordura brand is still known for today.

Superior Durability

The new fabric could withstand prolonged stress and use without breaking down. This made it ideal for products that see heavy, repeated use.

Enhanced Abrasion Resistance

One of the most notable improvements was its ability to resist surface wear. The nylon blend prevented fraying and thinning caused by rubbing against other surfaces.

Unmatched Tear Resistance

The fabric also gained immense strength against ripping and tearing. Once a small puncture or cut occurred, the nylon-infused weave helped prevent it from propagating further.

Common Trade-offs in High-Durability Fabrics

While the 1966 upgrade created an exceptionally tough material, it's important to understand the inherent trade-offs that come with such nylon-based, high-denier textiles. This context is crucial for any technical evaluation.

Breathability Considerations

Fabrics engineered for maximum durability often have a tight weave that can limit airflow. This makes them less breathable than natural fibers like cotton or wool, which is a key consideration for certain types of apparel.

Weight and Flexibility

Increasing tear and abrasion resistance often involves using heavier yarns and coatings. This can make the resulting fabric stiffer and heavier than less-durable alternatives.

Dyeing and UV Stability

Historically, synthetic fibers like nylon presented unique challenges for dyeing and long-term colorfastness, especially under prolonged UV exposure. While modern formulations have vastly improved this, it remains a fundamental area of innovation for all performance textiles.

How This Applies to Your Decision-Making

Understanding this pivotal moment in Cordura's history provides a framework for evaluating modern performance fabrics. The principles behind the 1966 upgrade still drive textile innovation today.

- If your primary focus is extreme durability: The legacy of the nylon blend is what you are seeking; look for high-denier Cordura fabrics that prioritize abrasion and tear resistance above all else.

- If your primary focus is a balance of performance: Recognize that the original innovation has spawned a family of fabrics, some of which blend Cordura with other materials like cotton or spandex to balance toughness with comfort and flexibility.

This strategic enhancement in 1966 was the pivotal moment that defined Cordura's legacy as a benchmark for toughness.

Summary Table:

| Key Upgrade (1966) | Primary Benefit | Key Application |

|---|---|---|

| Nylon Blend | Extreme Durability & Tear Resistance | Military Gear, Heavy-Duty Luggage |

| Enhanced Weave | Superior Abrasion Resistance | Workwear, Outdoor Equipment |

| Synthetic Engineering | Long-Lasting Performance | High-Stress Industrial Uses |

Need a Reliable Partner for High-Performance Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear built with the same principles of innovation and resilience that defined the 1966 Cordura upgrade. We specialize in creating boots and shoes for distributors, brand owners, and bulk clients who demand superior strength, abrasion resistance, and long-lasting performance.

Let us help you develop the perfect footwear solution for your market. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

People Also Ask

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style

- What are the steps to clean suede military boots? A Complete Guide to Gentle, Effective Care

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- Why are slip-resistant military boots important? The Foundation of Soldier Safety and Mission Success