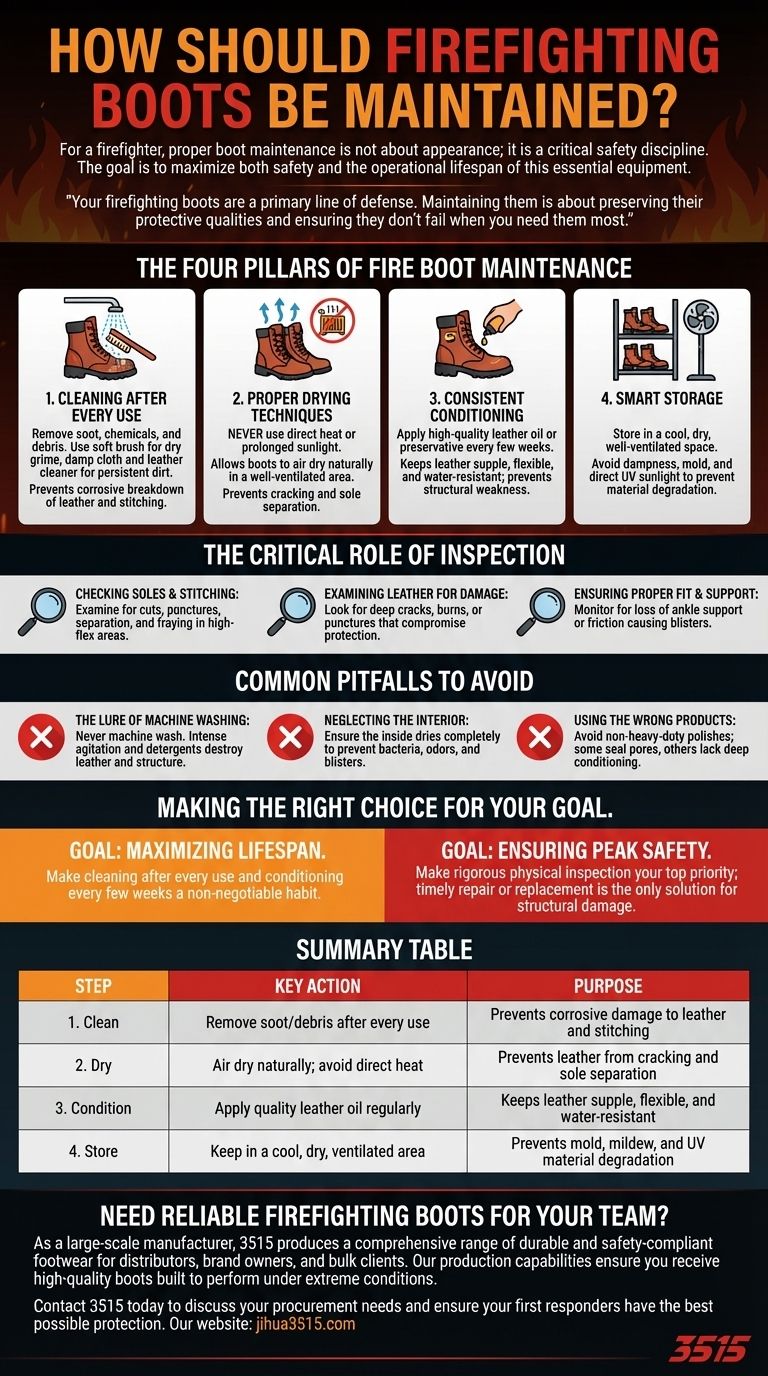

For a firefighter, proper boot maintenance is not about appearance; it is a critical safety discipline. The core process involves four distinct steps: cleaning to remove corrosive contaminants, inspecting for any signs of wear or structural failure, conditioning the leather to maintain its integrity, and storing the boots correctly to prevent material degradation.

Your firefighting boots are a primary line of defense. Maintaining them is about preserving their protective qualities and ensuring they don't fail when you need them most. The goal is to maximize both safety and the operational lifespan of this essential equipment.

The Four Pillars of Fire Boot Maintenance

Effective maintenance is a consistent cycle. Each step is designed to preserve the materials and structural integrity of the boot, ensuring it performs as designed under extreme conditions.

Step 1: Cleaning After Every Use

You must remove soot, chemicals, and other debris after each use. These contaminants can be abrasive and corrosive, actively breaking down the leather and stitching over time.

Use a soft-bristled brush to remove dry debris. For more persistent grime, a damp cloth and a specialized leather cleaner are recommended.

Step 2: Proper Drying Techniques

Never expose your boots to direct heat from a fire, heater, or even prolonged direct sunlight to speed up drying. This is a critical mistake.

High heat causes leather to shrink, crack, and become brittle. It can also weaken the adhesives used to bond the sole, leading to catastrophic failure. Always allow boots to air dry naturally in a well-ventilated area.

Step 3: Consistent Conditioning

Leather is a skin; without moisture, it dries out and cracks. Conditioning replenishes the natural oils needed to keep the material supple, flexible, and water-resistant.

Apply a high-quality leather oil or heavy-duty leather preservative every few weeks, or more often if the boots are frequently exposed to wet conditions. This simple step prevents cracks from forming, which are primary points of structural weakness.

Step 4: Smart Storage

How you store your boots between calls directly impacts their longevity. The ideal environment is a cool, dry, and well-ventilated space.

Avoid damp or humid environments that promote mold and mildew, which can destroy leather. Storing them away from direct sunlight also prevents UV damage that can degrade boot materials over time.

The Critical Role of Inspection

Cleaning provides the perfect opportunity for a thorough inspection. This is where you proactively identify potential points of failure before they become a danger on the fireground.

Checking Soles and Stitching

Carefully examine the soles for deep cuts, punctures, or signs of separation from the upper part of the boot. Check all stitching, especially in high-flex areas, for any signs of fraying or coming undone.

Examining the Leather for Damage

Look for any deep cracks, burns, or punctures that could compromise the boot's protective barrier. A small crack today can become a complete tear during a critical moment.

Ensuring Proper Fit and Support

Pay attention to how the boot feels. Over time, the internal support structure can break down. If you notice a loss of ankle support or a fit that causes friction and blisters, the boot is no longer providing adequate protection and may be contributing to fatigue.

Common Pitfalls to Avoid

Knowing what not to do is as important as knowing the correct procedures. These common mistakes can ruin an expensive and vital piece of safety equipment.

The Lure of Machine Washing

Never put your leather firefighting boots in a washing machine. The intense agitation, prolonged water submersion, and harsh detergents will strip the leather of its essential oils and can severely damage the boot's structure.

Neglecting the Interior

While focusing on the exterior, it's easy to forget the inside. Ensure the interior of the boot dries completely to prevent bacterial growth and odors. A boot that is wet on the inside can also compromise fit and lead to blisters.

Using the Wrong Products

Avoid using polishes or creams that are not designed for heavy-duty work boots. Some products may seal the leather's pores, preventing it from breathing, while others may not offer the deep conditioning required for firefighting footwear.

Making the Right Choice for Your Goal

Your maintenance routine should align with your primary objective, whether it's maximizing value or ensuring absolute readiness.

- If your primary focus is maximizing lifespan: Make cleaning after every single use and conditioning every few weeks a non-negotiable habit.

- If your primary focus is ensuring peak safety: Make rigorous physical inspection your top priority, understanding that timely repair or replacement is the only solution for structural damage.

Ultimately, disciplined boot maintenance is a direct investment in your personal safety and professional readiness.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Clean | Remove soot/debris after every use | Prevents corrosive damage to leather and stitching |

| 2. Dry | Air dry naturally; avoid direct heat | Prevents leather from cracking and sole separation |

| 3. Condition | Apply quality leather oil regularly | Keeps leather supple, flexible, and water-resistant |

| 4. Store | Keep in a cool, dry, ventilated area | Prevents mold, mildew, and UV material degradation |

Need Reliable Firefighting Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive high-quality boots built to perform under extreme conditions.

Contact 3515 today to discuss your procurement needs and ensure your first responders have the best possible protection.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the benefits of the sole in police boots? Enhance Officer Safety and Endurance

- What materials are commonly used for the upper part of police boots? A Guide to Durability & Performance

- What shoes do police officers wear? Essential Footwear for Safety and Endurance

- How do well-designed law enforcement boots improve job performance? Enhance Officer Safety and Agility

- What are the three main components of police footwear? The Anatomy of a High-Performance Duty Boot

- What is the overall advice for selecting the right police boots? Prioritize Fit, Durability & Safety

- Why might an officer prefer police shoes over boots? For Superior Comfort & Agility on Duty

- What are the advantages of police boots? Superior Protection, Support & Durability for Law Enforcement