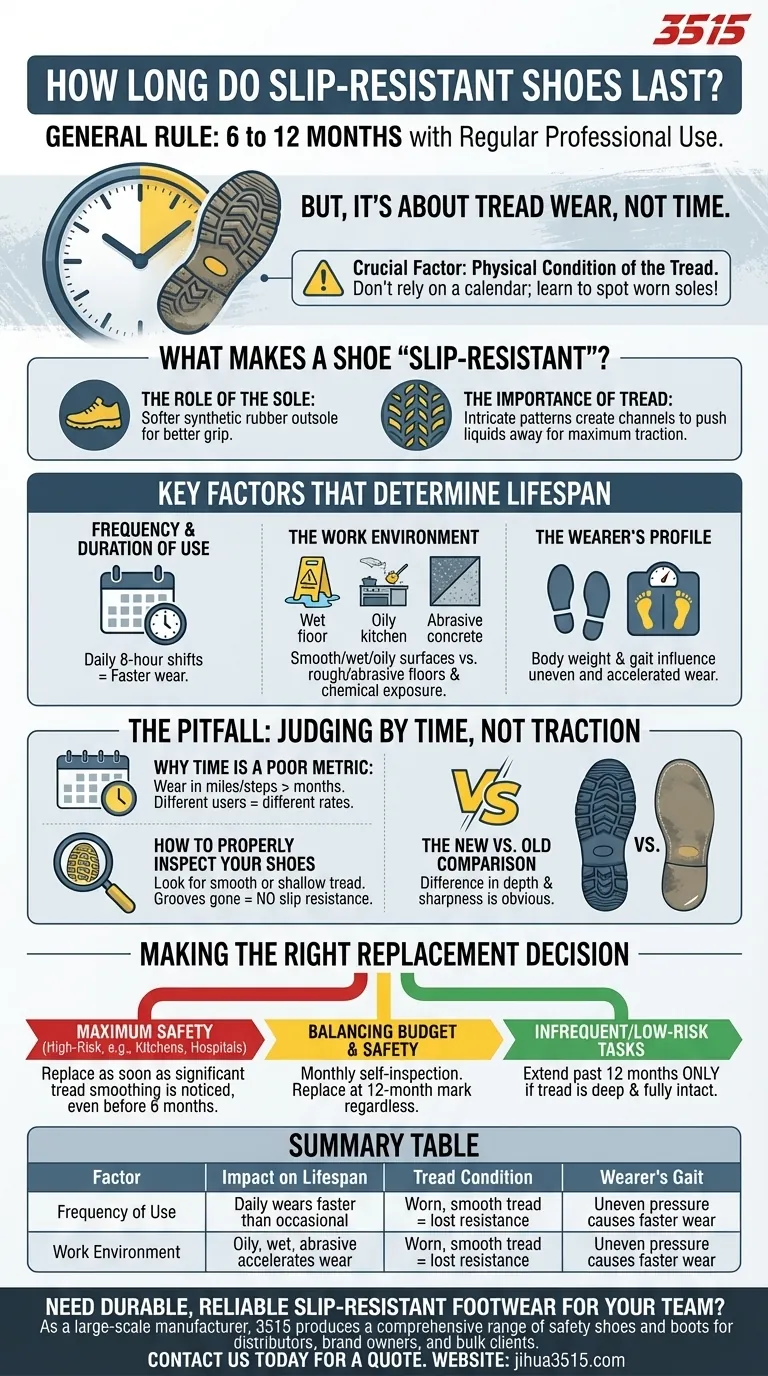

As a general rule, slip-resistant shoes last between six and twelve months with regular professional use. However, this timeframe is only a guideline, as the actual lifespan is determined by the rate of wear on the sole, not the calendar.

The most critical factor in a slip-resistant shoe's lifespan is the physical condition of its tread. Relying solely on a time-based replacement schedule can be misleading; you must instead learn to identify the signs of a worn-out, unsafe sole.

What Makes a Shoe "Slip-Resistant"?

The Role of the Sole

The safety of a slip-resistant shoe comes almost entirely from its outsole. Unlike standard shoes, these are made from softer synthetic rubber compounds designed to provide a better grip.

The Importance of Tread

These specialized soles feature intricate tread patterns. These patterns create channels that push liquids like water and oil away from the bottom of the shoe, allowing the sole to make direct contact with the surface for maximum traction.

Key Factors That Determine Lifespan

The 6-to-12-month estimate can change dramatically based on several key variables.

Frequency and Duration of Use

A shoe worn for an eight-hour shift five days a week will wear down significantly faster than one used less frequently. Many employers who require this footwear offer annual stipends, acknowledging this expected wear cycle.

The Work Environment

The surfaces you walk on have a major impact. Smooth, wet, or oily floors in a kitchen or hospital cause different wear than rough, abrasive concrete floors. Constant exposure to chemicals or grease can also degrade the rubber sole more quickly.

The Wearer's Profile

Your body weight and walking pattern, or gait, influence how quickly the tread wears down. Individuals who put more pressure on specific parts of the heel or forefoot will see uneven and accelerated wear in those areas.

The Pitfall: Judging by Time, Not Traction

Relying on a fixed timeline is the most common mistake. A shoe can look perfectly fine from the top while its sole is dangerously worn out.

Why Time is a Poor Metric

Measuring wear in miles or steps is more accurate than months. Two workers in the same role can have vastly different walking distances over a single shift, causing their shoes to wear out at different rates.

How to Properly Inspect Your Shoes

You must inspect the tread pattern on the outsole. Look for areas where the pattern has become smooth or shallow. If the intricate grooves are gone, the shoe can no longer channel away liquids and has lost its slip-resistant properties.

The New vs. Old Comparison

The easiest way to spot wear is to compare your shoe to a new one of the same model. The difference in tread depth and sharpness will make it immediately obvious when a replacement is necessary.

Making the Right Replacement Decision

Your replacement strategy should be based on your personal risk and environment.

- If your primary focus is maximum safety in a high-risk environment (e.g., kitchens, hospitals): Replace your shoes as soon as you notice any significant smoothing of the tread, even if it's before the six-month mark.

- If your primary focus is balancing budget with safety: Institute a monthly self-inspection of the shoe's tread and replace them at the 12-month mark regardless of condition.

- If you use them for infrequent or low-risk tasks: You may extend past 12 months, but only if a thorough inspection shows the tread is still deep and fully intact across the entire sole.

Ultimately, your safety depends on traction, and a worn-out tread offers a false sense of security.

Summary Table:

| Factor | Impact on Lifespan |

|---|---|

| Frequency of Use | Daily use wears soles faster than occasional use. |

| Work Environment | Oily, wet, or abrasive surfaces accelerate wear. |

| Tread Condition | Worn, smooth tread = lost slip resistance. |

| Wearer's Gait | Uneven pressure can cause faster, uneven wear. |

Need durable, reliable slip-resistant footwear for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures your workforce has the traction and protection they need. Contact us today for a quote and secure your supply of high-performance footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites