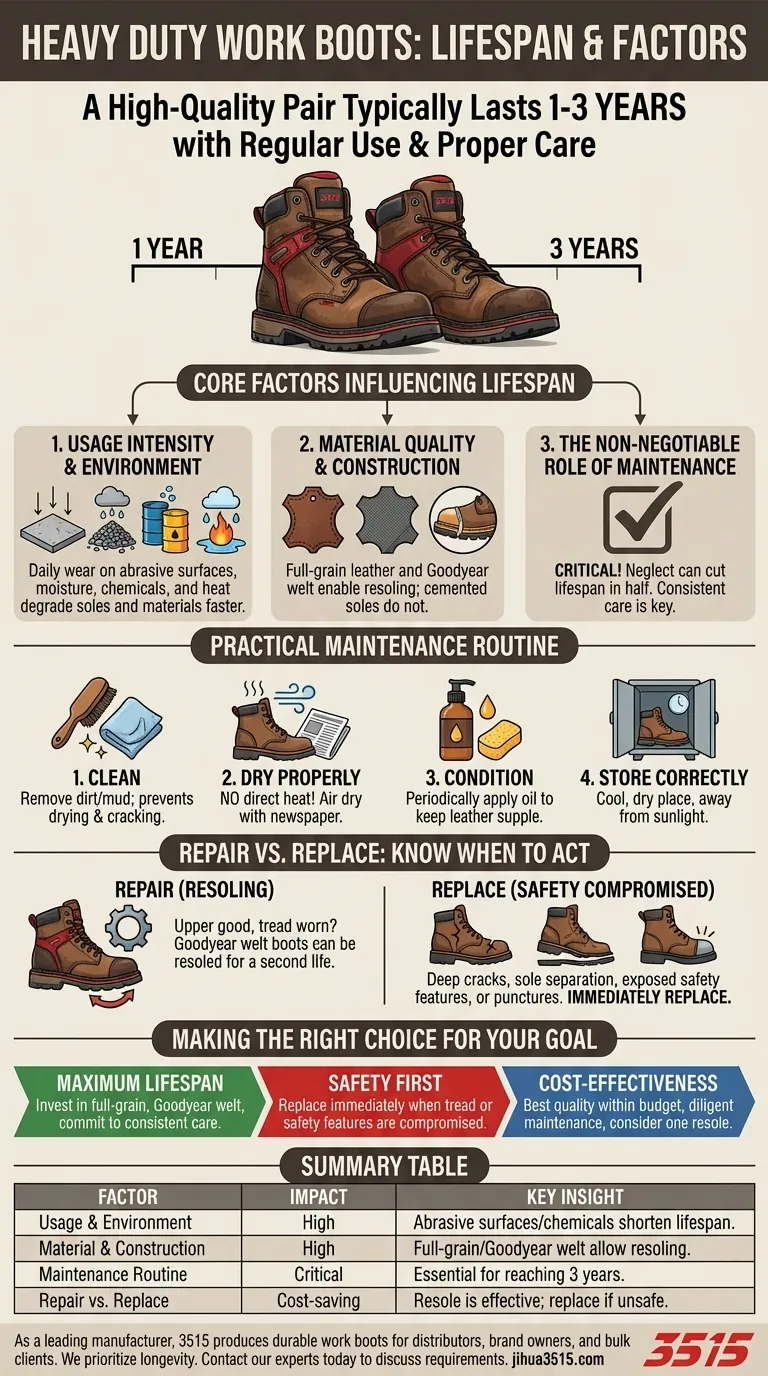

To be direct, a pair of high-quality, heavy-duty work boots should last between one and three years with regular use. This range is not arbitrary; it's a direct reflection of the materials used, the intensity of your work environment, and, most importantly, the consistency of your maintenance routine.

The lifespan of your work boots is not a fixed date on a calendar. It is a variable outcome that you directly influence through proper care and an understanding of when critical components have reached their functional limit.

The Core Factors Influencing Boot Lifespan

A boot's longevity is determined by a balance of three key elements. Understanding them allows you to make a better initial purchase and extend its functional life.

Usage Intensity and Work Environment

The single biggest factor is how and where you use your boots. Daily wear on abrasive surfaces like concrete or gravel will degrade soles far faster than work on softer ground.

Exposure to moisture, chemicals, or extreme heat also accelerates the breakdown of leather and adhesives, demanding more frequent maintenance.

Material Quality and Construction

Higher-quality materials inherently last longer. Full-grain leather, for example, is more durable and resilient than synthetic alternatives when properly cared for.

Construction methods also matter. Boots with a Goodyear welt construction can be resoled, effectively giving them a second life. Cemented (glued) soles, common on lighter boots, cannot be replaced once they wear out.

The Non-Negotiable Role of Maintenance

Proper care is not a suggestion; it's a requirement for achieving the upper end of the 1-3 year lifespan. Neglect can cut a boot's life in half.

A simple, consistent maintenance routine is the most cost-effective way to protect your investment.

A Practical Maintenance Routine

This routine prevents the most common causes of premature boot failure.

Regular Cleaning

Use a damp cloth or brush to remove dirt and debris after use. Caked-on mud can draw moisture out of leather as it dries, causing it to become brittle and crack.

Proper Drying

If your boots get wet, never use direct heat (like a radiator or fire) to dry them. This can permanently damage the leather. Stuff them with newspaper and let them air dry slowly.

Leather Conditioning

Periodically apply a quality leather oil or conditioner. This replenishes the natural oils in the leather, keeping it supple and preventing cracks.

Correct Storage

Store your boots in a cool, dry place away from direct sunlight. This prevents the materials from drying out and becoming brittle over time.

Understanding the Trade-offs: Repair vs. Replace

Knowing when to retire a pair of boots is a matter of safety, not just appearance.

When to Repair

The most common and worthwhile repair is resoling. If the upper part of the boot is still in good condition but the tread is worn down, resoling a well-constructed (e.g., Goodyear welted) boot is an excellent way to extend its life.

When to Replace

Replacement is non-negotiable when a boot's core structure or safety features are compromised.

Look for deep cracks in the leather, separation between the upper and the sole, or a compressed midsole that no longer provides support. Crucially, if a steel toe becomes exposed or the sole is punctured, the boot must be replaced immediately.

Making the Right Choice for Your Goal

Use your primary need to guide your approach to buying and maintaining your work boots.

- If your primary focus is maximum lifespan: Invest in high-quality, full-grain leather boots with a Goodyear welt construction and commit to a consistent cleaning and conditioning schedule.

- If your primary focus is safety above all else: Replace your boots as soon as the tread is significantly worn or any safety feature (like a protective toe or shank) is compromised, regardless of age.

- If your primary focus is cost-effectiveness: Choose the best quality boot within your budget and extend its life with diligent maintenance, considering a resole once before a full replacement.

Ultimately, treating your work boots as a critical piece of equipment is an investment in your own safety and comfort on the job.

Summary Table:

| Factor | Impact on Lifespan | Key Insight |

|---|---|---|

| Usage & Environment | High | Abrasive surfaces, chemicals, and moisture can drastically shorten lifespan. |

| Material & Construction | High | Full-grain leather and Goodyear welt construction allow for resoling and longer use. |

| Maintenance Routine | Critical | Proper cleaning, drying, and conditioning are essential to reach the 3-year mark. |

| Repair vs. Replace | Cost-saving | Resoling is cost-effective; replace if safety features are compromised. |

As a leading manufacturer, 3515 produces durable work boots for distributors, brand owners, and bulk clients. We understand that longevity is paramount. Our production capabilities cover all types of safety footwear built with high-quality materials and construction methods designed to last. Let us help you source boots that meet your durability and safety standards.

Ready to equip your workforce with reliable footwear? Contact our experts today to discuss your requirements and explore our comprehensive range.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health