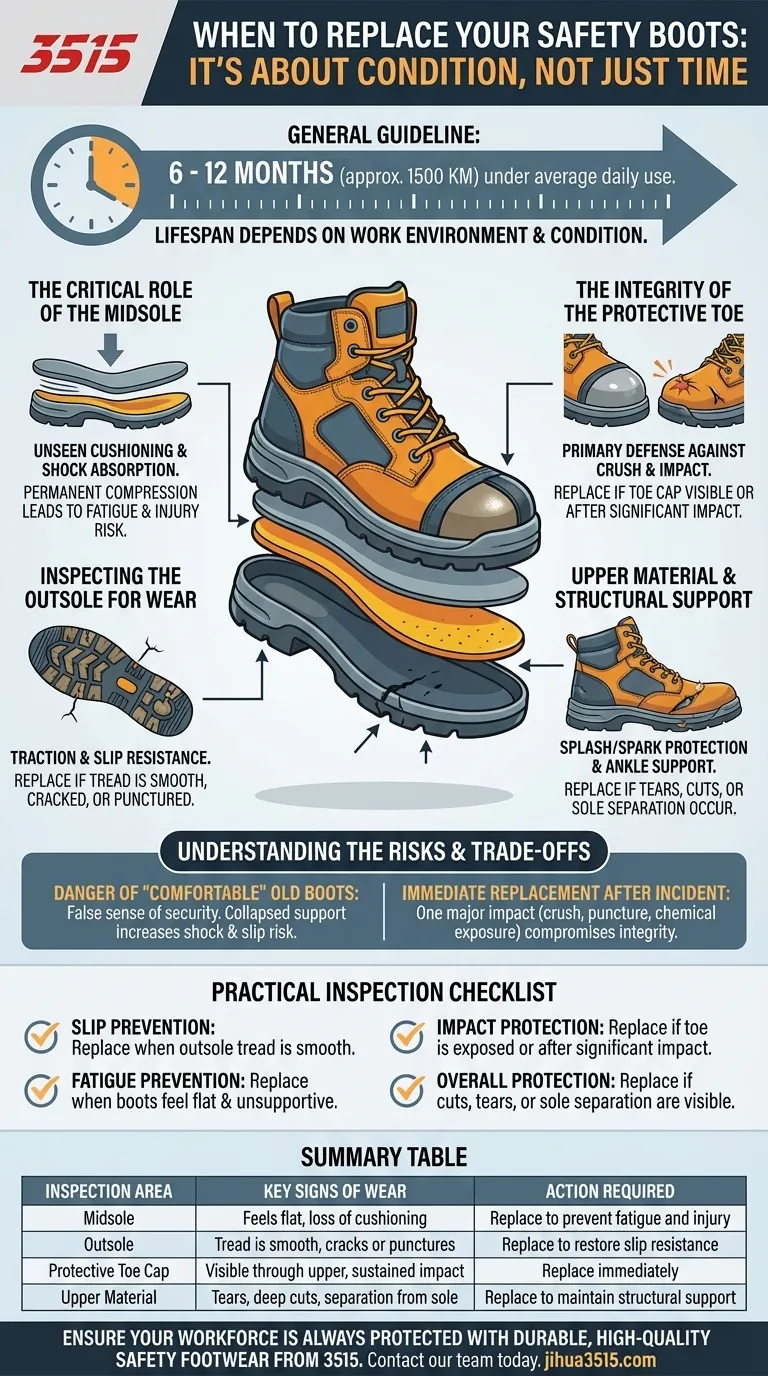

As a general guideline, you can expect to replace safety boots every 6 to 12 months under average daily use. The reference point of 1500 km is a reasonable estimate for when significant wear begins, but this is not a strict rule. The actual lifespan is determined entirely by the boot's condition, your work environment, and any specific incidents that occur.

The most critical takeaway is this: A safety boot's expiration is not set by a calendar date, but by the physical failure of its protective components. Regular, thorough inspection is the only reliable way to know when it's time for a replacement.

Beyond the Calendar: Key Failure Points in Safety Footwear

A boot's age in months is the least important metric for determining its viability. Instead, you must learn to assess the condition of the specific components responsible for keeping you safe.

The Critical Role of the Midsole

The midsole is the unseen layer of cushioning between the outsole (the part that touches the ground) and your foot. Its primary job is shock absorption.

Over time, this material permanently compresses, losing its ability to cushion impact. This leads directly to foot, leg, and even back fatigue, increasing the risk of long-term injury.

Inspecting the Outsole for Wear

The outsole provides traction and slip resistance. Once the tread pattern wears down and becomes smooth, the boot's grip on wet or oily surfaces is severely compromised.

Look for areas where the tread is gone, or for any deep cracks, splits, or punctures that could allow liquids or sharp objects to penetrate the boot.

The Integrity of the Protective Toe

The protective toe cap (whether steel, composite, or alloy) is your primary defense against crush and impact injuries.

If the toe cap becomes visible through the upper material due to abrasion, the boot must be replaced. More importantly, any boot that has sustained a significant impact must be retired immediately, even if there is no visible damage. The internal structure could be compromised.

Upper Material and Structural Support

The upper part of the boot protects you from splashes, sparks, and abrasions while also providing crucial ankle support.

Tears, deep cuts, or separation of the upper from the sole render the boot unsafe. This structural failure eliminates its protective qualities and reduces the stability needed to prevent sprains and falls.

Understanding the Trade-offs and Risks

Continuing to wear degraded safety footwear creates a false sense of security. It's crucial to prioritize safety over comfort or cost.

The Danger of "Comfortable" Old Boots

A heavily worn boot may feel comfortable because it has molded to your foot, but this comfort is deceptive. The supportive structures, particularly the midsole, have likely collapsed.

This lack of support means every step sends more shock through your body, and the compromised outsole offers inadequate protection against slips.

When to Replace After an Incident

The rule is simple and absolute: replace your boots after any single major incident.

This includes a heavy object falling on the toe, a sharp object attempting to puncture the sole, or significant chemical exposure. The boot has done its job once; its integrity cannot be guaranteed for a second event.

The Impact of Environment

The environment you work in dramatically accelerates wear. Boots used on rough gravel, in contact with chemicals, or constantly exposed to wet conditions will have a much shorter lifespan than those used on a smooth, dry factory floor.

A Practical Inspection Checklist

Use this checklist weekly or after any demanding shift to make an informed decision about your footwear.

- If your primary focus is slip prevention: Immediately replace boots when the outsole tread becomes smooth in key contact areas.

- If your primary focus is preventing fatigue and strain: Replace your boots when they feel flat and unsupportive underfoot, even if the exterior looks acceptable.

- If your primary focus is impact protection: Replace your boots the moment the safety toe becomes exposed or after they have sustained any significant impact.

- If your primary focus is overall protection and support: Replace your boots when you see any cuts, tears, or separation between the upper material and the sole.

Ultimately, inspecting your boots is a fundamental part of taking control of your own safety at work.

Summary Table:

| Inspection Area | Key Signs of Wear | Action Required |

|---|---|---|

| Midsole | Feels flat, loss of cushioning | Replace to prevent fatigue and injury |

| Outsole | Tread is smooth, cracks or punctures | Replace to restore slip resistance |

| Protective Toe Cap | Visible through upper, sustained impact | Replace immediately |

| Upper Material | Tears, deep cuts, separation from sole | Replace to maintain structural support |

Ensure your workforce is always protected with durable, high-quality safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive reliable footwear designed to withstand demanding work environments. Don't compromise on safety—contact our team today to discuss your needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Premium Waterproof Nubuck Safety Boots for Wholesale

People Also Ask

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection