To incorporate a steel head into a PVC rain boot, manufacturers use a process called insert molding. The standard steel head is placed directly into the boot-shaped mold before the molten PVC material is injected. The liquid PVC then flows around the steel component, encapsulating it completely and forming a permanent, mechanical bond as it cools and solidifies into the final boot shape.

The core principle is simple and effective: the boot is not assembled from separate parts, but rather formed around the steel toe in a single manufacturing step, ensuring the protective component is an inseparable part of the final structure.

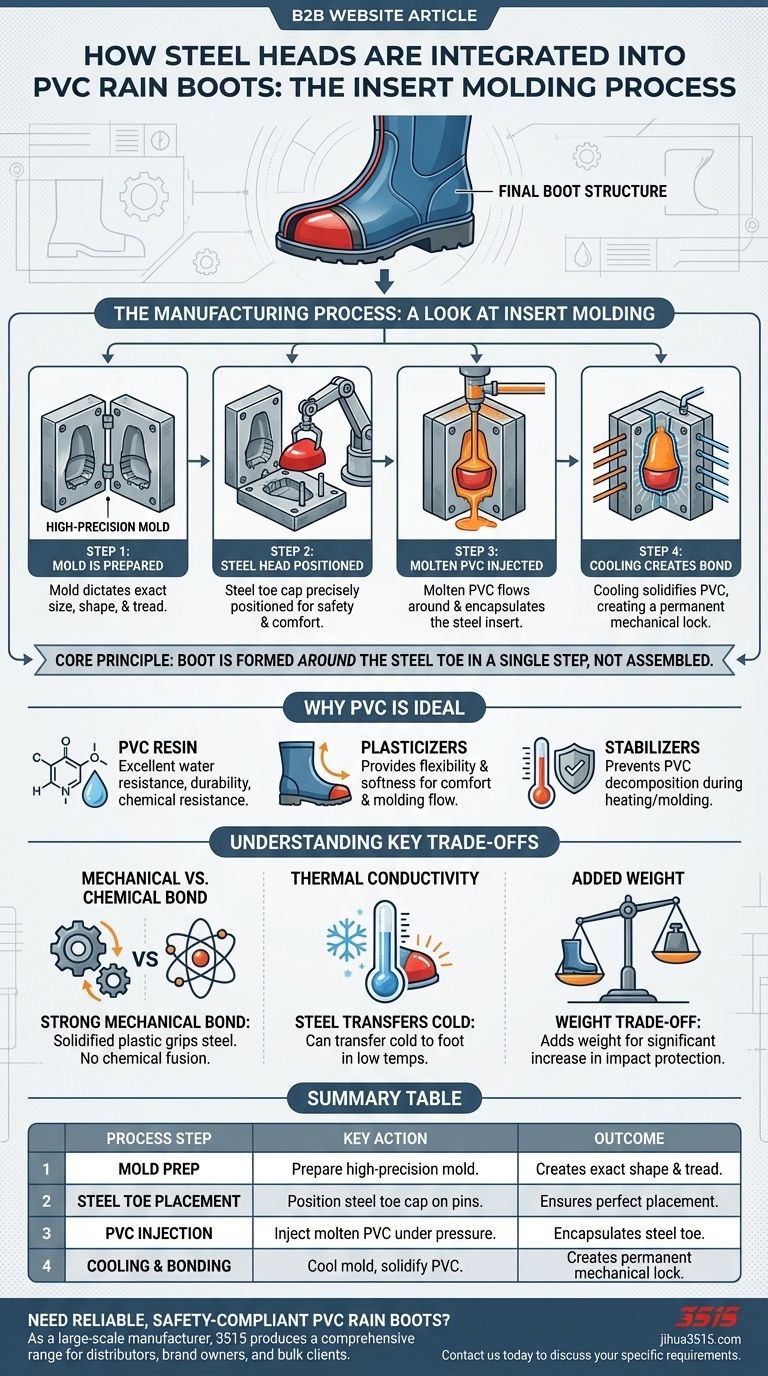

The Manufacturing Process: A Look at Insert Molding

The integration of a rigid component like a steel toe into a flexible material like PVC is a classic example of insert injection molding. This process is highly efficient and creates a robust final product.

Step 1: The Mold is Prepared

The process begins with a high-precision, two-part steel mold. This mold is the negative space of the final boot, dictating its exact size, shape, and tread pattern.

Step 2: The Steel Head is Positioned

Before the mold is closed, a standard steel head (or "toe cap") is manually or robotically placed onto locating pins inside the mold. This precision is critical to ensure the toe cap is perfectly positioned in the final product for maximum safety and comfort.

Step 3: Molten PVC is Injected

Once the steel head is secure and the mold is closed, molten PVC is injected under high pressure. This hot, liquid plastic flows into every cavity of the mold, completely surrounding the steel insert.

Step 4: Cooling Creates a Permanent Bond

The mold is then cooled. As the PVC cools and solidifies, it shrinks slightly, gripping the steel toe cap tightly. This creates an incredibly strong mechanical lock, making the steel toe an integral and permanent part of the boot's structure.

Why PVC is Ideal for This Application

The specific properties of Polyvinyl Chloride (PVC) and its additives are what make this seamless integration possible and effective.

The Role of PVC Resin

The base PVC resin provides the fundamental characteristics of the boot: excellent water resistance, durability, and resistance to chemicals like acids and oils.

The Function of Plasticizers

Plasticizers are critical additives that give the PVC its flexibility and softness. This allows the boot to be comfortable to wear while still being tough enough to flow perfectly around the steel insert during molding.

The Need for Stabilizers

During the heating and molding process, PVC can begin to decompose. Stabilizers are added to the mixture to prevent this, ensuring the material maintains its structural integrity and performance characteristics in the finished boot.

Understanding the Key Trade-offs

While insert molding is an excellent method, it's important to understand the inherent characteristics and limitations of integrating a steel toe in this way.

Mechanical vs. Chemical Bond

The bond between the PVC and the steel toe is purely mechanical. The solidified plastic grips the steel component; they do not chemically fuse. This is an extremely strong and reliable bond for footwear applications.

Thermal Conductivity

Steel is an excellent thermal conductor. In cold environments, the steel toe can transfer cold to the wearer's foot more readily than the rest of the boot, potentially causing discomfort.

Added Weight

The inclusion of a solid steel component inevitably adds weight to the footwear compared to non-safety alternatives. This is a direct trade-off for the significant increase in impact and compression protection.

Making the Right Choice for Your Needs

Understanding how a steel toe is integrated helps you evaluate safety footwear based on its core construction.

- If your primary focus is certified impact protection: The insert molding process ensures the steel toe is properly and permanently encapsulated, meeting established safety standards reliably.

- If your primary focus is all-day comfort: Be mindful of the added weight of steel-toed boots and look for designs that prioritize ergonomic shapes and cushioning.

- If your primary focus is working in cold climates: Consider boots with integrated insulation to counteract the thermal conductivity of the steel toe cap.

By understanding the manufacturing process, you can better appreciate the balance between safety, material science, and design in your footwear.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| 1. Mold Preparation | High-precision steel mold is prepared. | Creates the exact shape and tread of the final boot. |

| 2. Steel Toe Placement | Steel toe cap is positioned on pins inside the mold. | Ensures perfect placement for safety and comfort. |

| 3. PVC Injection | Molten PVC is injected under high pressure. | Liquid PVC flows around and completely encapsulates the steel toe. |

| 4. Cooling & Bonding | The mold is cooled, solidifying the PVC. | Creates a permanent, mechanical lock between the PVC and steel. |

Need reliable, safety-compliant PVC rain boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel-toed footwear for distributors, brand owners, and bulk clients. Our expertise in insert molding ensures your footwear meets the highest standards of impact protection and durability.

Contact us today to discuss your specific requirements and leverage our full production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What features should the best wellington boots provide? A Guide to Material, Lining & Sole

- What type of socks should children wear with wellies to keep feet warm? Choose Wool or Thermal Materials

- What features should be considered when choosing wellies for toddlers and babies? A Guide to Safety & Comfort

- How can you shine rubber boots? Restore Their Like-New Shine with Simple Conditioning

- What should you do if your Wellington boots get damaged? A Guide to Repair and Longevity

- What features of wellington boots help prevent slips? The Science of Grip in Slippery Conditions

- What should you consider when choosing shoes for wet weather? Key Features for Dry, Safe Feet

- What materials are commonly used to make gumboots? Rubber vs. PVC for Durability & Comfort