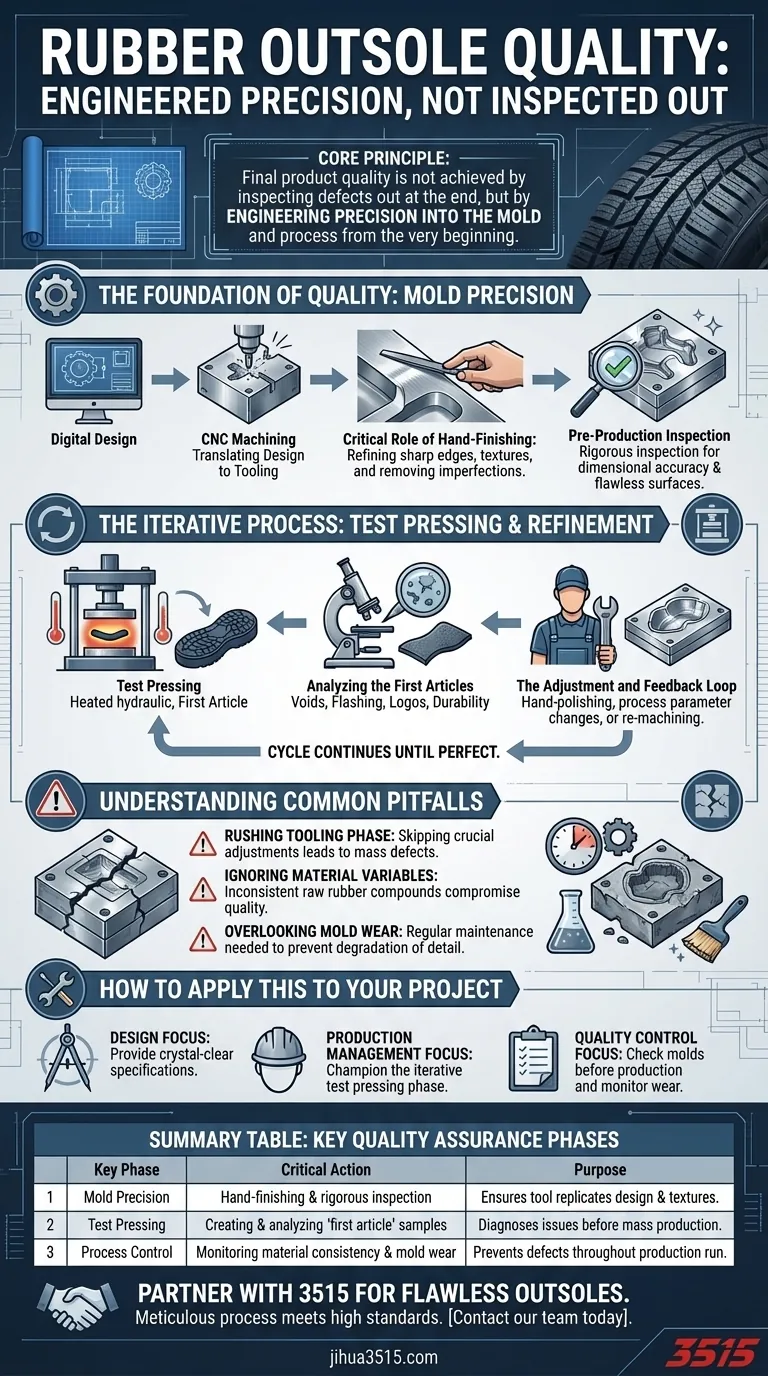

In short, rubber outsole quality is ensured through a meticulous, two-stage process that focuses on perfecting the tooling before mass production ever begins. It involves the precise hand-finishing and inspection of the production molds, followed by an iterative cycle of test pressing and adjustment to guarantee every detail meets design specifications.

The core principle is that final product quality is not achieved by inspecting defects out at the end, but by engineering precision into the mold and the process from the very beginning.

The Foundation of Quality: Mold Precision

The physical mold is the single most critical asset in outsole production. Its quality directly dictates the quality of every single part that will be made from it.

Translating Design to Tooling

An outsole begins as a digital design. This design is then used to create a physical mold, typically from steel or aluminum.

This translation from digital file to physical tool is the first critical point where errors can occur. Ensuring the mold matches the design specifications with extreme accuracy is paramount.

The Critical Role of Hand-Finishing

Even with advanced CNC machining, molds require manual hand-finishing. This highly skilled process is essential for refining sharp edges, perfecting surface textures, and removing any minute imperfections left by the machining process.

Without this step, subtle but critical design details, like the texture needed for grip, would be lost or inconsistent.

Pre-Production Inspection

Before any rubber is pressed, the mold itself undergoes a rigorous inspection. Quality engineers check for dimensional accuracy against the original design, ensure all details are sharp, and verify that the mold surfaces are flawless.

The Iterative Process: Test Pressing and Refinement

Once the mold is approved, the process moves to iterative testing. This is where the mold's performance is validated with the actual rubber compound.

What is Test Pressing?

Test pressing involves creating a small number of "first article" outsoles using the finished mold. This is the first time the design is rendered in its final material.

These initial samples are not intended for sale; their sole purpose is to diagnose any issues with the mold or the process parameters (like temperature, pressure, and cure time).

Analyzing the First Articles

The test samples are scrutinized for a range of potential defects. Engineers look for incomplete filling (voids), excess material leaking from the mold (flashing), and ensure the surface texture and logos are perfectly replicated.

They also perform physical tests to confirm the rubber cured correctly and will meet durability standards.

The Adjustment and Feedback Loop

Based on the analysis of the test samples, adjustments are made. This might involve further hand-polishing of the mold, altering process parameters, or even re-machining small sections of the tooling.

A new round of test pressing is then conducted. This "press, analyze, adjust" loop continues until the outsoles produced are a perfect, repeatable match for the design intent.

Understanding the Common Pitfalls

Achieving consistent quality requires avoiding common traps that compromise the integrity of the manufacturing process.

Rushing the Tooling Phase

The most significant pitfall is rushing the mold-making and test-pressing stages. Pressure to start full-scale production can lead to skipping crucial adjustments, resulting in thousands of defective parts down the line.

Ignoring Material Variables

A perfect mold can still produce a faulty part if the rubber compound is inconsistent. Quality assurance must also include rigorous testing of the raw material batches to ensure they meet the required specifications for hardness, elasticity, and color.

Overlooking Mold Wear

Production molds do not last forever. Over a long production run, the high pressure and heat can cause microscopic wear, leading to a degradation in detail. A robust quality plan includes regular mold inspection and maintenance schedules.

How to Apply This to Your Project

Ensuring quality is about focusing on the right stage of the process based on your role.

- If your primary focus is design: Provide crystal-clear specifications for textures, edge sharpness, and critical dimensions to guide the mold makers.

- If your primary focus is production management: Champion the iterative test pressing phase and protect it from timeline pressures, as this is your best tool for preventing costly errors.

- If your primary focus is quality control: Implement a system that checks the mold itself before production and monitors for mold wear throughout the entire run, not just the final product.

Ultimately, exceptional outsole quality is the direct result of a disciplined, front-loaded process that prioritizes precision long before the first product is ever shipped.

Summary Table:

| Key Quality Assurance Phase | Critical Action | Purpose |

|---|---|---|

| Mold Precision | Hand-finishing & rigorous inspection of the mold | Ensures the tool perfectly replicates the design, including textures and logos. |

| Test Pressing | Creating and analyzing initial "first article" samples | Diagnoses and corrects issues with mold or process before mass production. |

| Process Control | Monitoring material consistency and mold wear | Prevents defects and maintains quality throughout the entire production run. |

Partner with 3515 for Flawless Outsoles

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our commitment to the meticulous process described above guarantees that every pair of shoes and boots we produce meets the highest standards of durability and design accuracy.

Let us apply our disciplined production expertise to your project. Contact our team today to discuss your outsole and footwear manufacturing needs.

Visual Guide

Related Products

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is choosing the right work boot important? The Ultimate Guide to Industry-Specific Footwear Safety

- How did the brand's fabric technology evolve in the 1970s? From Industrial Toughness to Urban Softness

- How should you air out work shoes to keep them fresh? A Guide to Eliminating Odor & Extending Lifespan

- How does the drainage design of anti-slip footwear contribute to stability during zero-degree temperature transitions?

- What are the protective advantages of professional safety shoes? Crucial Safety for Fiber Extraction and Finishing