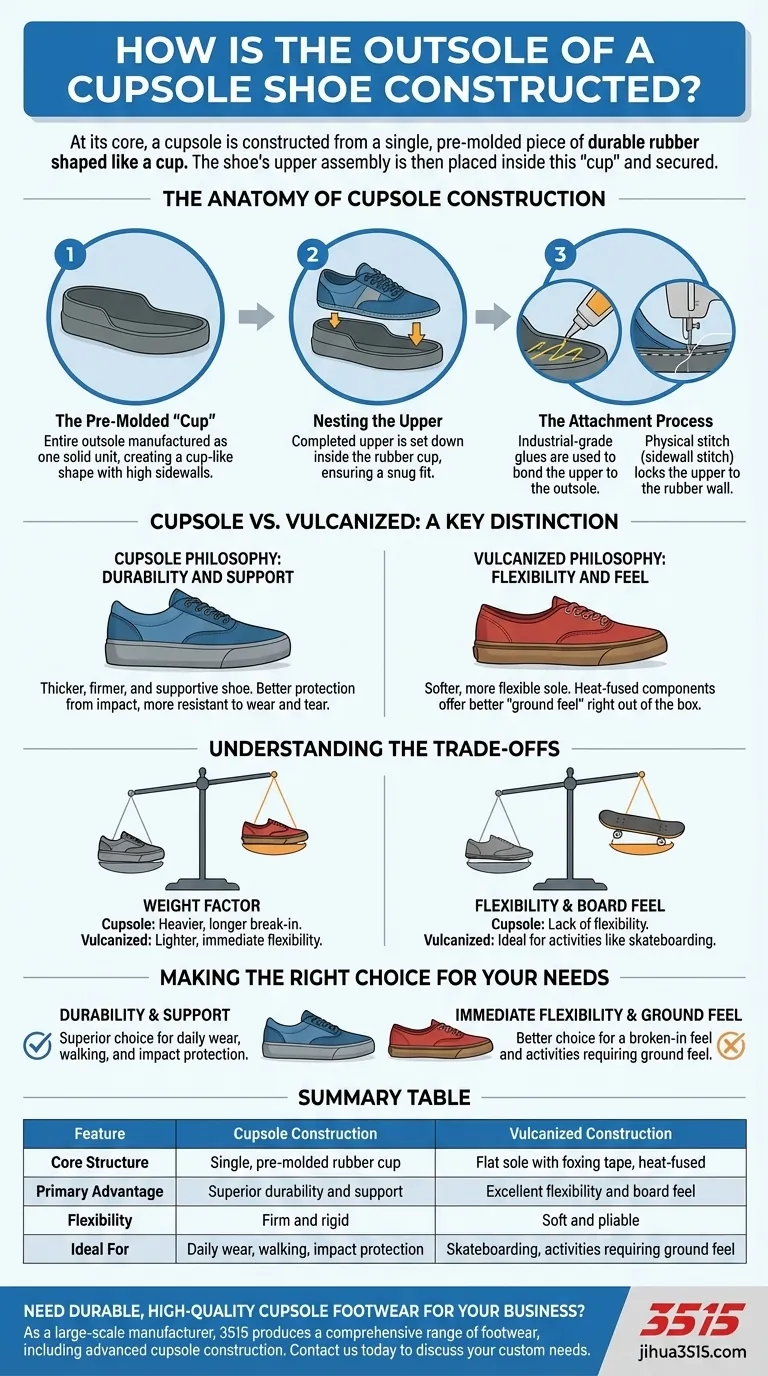

At its core, a cupsole is constructed from a single, pre-molded piece of durable rubber shaped like a cup. The shoe's upper assembly is then placed inside this "cup" and secured, most commonly with high-strength adhesives or by stitching it directly to the outsole's raised sidewalls.

The cupsole construction method prioritizes durability and support by creating a protective, pre-formed foundation that encases the bottom of the shoe's upper, in direct contrast to the heat-fused flexibility of a vulcanized sole.

The Anatomy of Cupsole Construction

Understanding the cupsole begins with visualizing its distinct, three-dimensional shape. It isn't built onto the shoe; rather, the shoe is built into it.

The Pre-Molded "Cup"

The entire outsole is manufactured as one solid unit. This process involves creating a rubber sole with high sidewalls, forming a cup-like shape that gives the construction its name.

Nesting the Upper

The completed upper part of the shoe, which includes all the fabric or leather panels, is then carefully set down inside this rubber cup. This ensures a snug and precise fit before the two components are permanently joined.

The Attachment Process

The final, critical step is to bond the upper to the outsole. This is typically achieved in one of two ways: powerful, industrial-grade glues or a physical stitch (often called a sidewall stitch) that runs along the perimeter of the shoe, locking the upper to the rubber wall.

Cupsole vs. Vulcanized: A Key Distinction

The value of the cupsole is best understood when compared to its primary alternative in casual footwear: the vulcanized sole.

The Cupsole Philosophy: Durability and Support

Cupsole construction results in a thicker, firmer, and often more supportive shoe. The substantial rubber base provides better protection from impact and is generally more resistant to wear and tear over time.

The Vulcanized Philosophy: Flexibility and Feel

A vulcanized shoe uses a different method. A flat rubber outsole is attached to the upper and then sealed with a strip of rubber "foxing tape" around the edge. The entire shoe is then heated in an oven, which bonds the components together, resulting in a much softer, more flexible sole with a better "ground feel."

Understanding the Trade-offs

Neither construction method is inherently superior; they simply serve different purposes and come with different compromises.

The Weight Factor

The durable, thick rubber of a cupsole makes it noticeably heavier and more rigid than a vulcanized sole. This often translates to a longer break-in period.

Flexibility and Board Feel

The primary trade-off for a cupsole's durability is a lack of flexibility. For activities like skateboarding, where feeling the board's contour is critical, the thinner and more pliable vulcanized sole is often preferred.

Making the Right Choice for Your Needs

Choosing between these constructions depends entirely on your priority.

- If your primary focus is durability and foot support: A cupsole is the superior choice for its protective, long-lasting construction, making it ideal for daily wear and walking.

- If your primary focus is immediate flexibility and ground feel: A vulcanized shoe will better serve your needs, offering a broken-in feel right out of the box.

Ultimately, understanding how your shoe's foundation is built is the key to selecting footwear that truly performs for its intended purpose.

Summary Table:

| Feature | Cupsole Construction | Vulcanized Construction |

|---|---|---|

| Core Structure | Single, pre-molded rubber cup | Flat sole with foxing tape, heat-fused |

| Primary Advantage | Superior durability and support | Excellent flexibility and board feel |

| Flexibility | Firm and rigid | Soft and pliable |

| Ideal For | Daily wear, walking, impact protection | Skateboarding, activities requiring ground feel |

Need durable, high-quality cupsole footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced cupsole construction designed for long-lasting performance.

Contact us today to discuss your custom footwear needs and leverage our manufacturing expertise to build a superior product line.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance