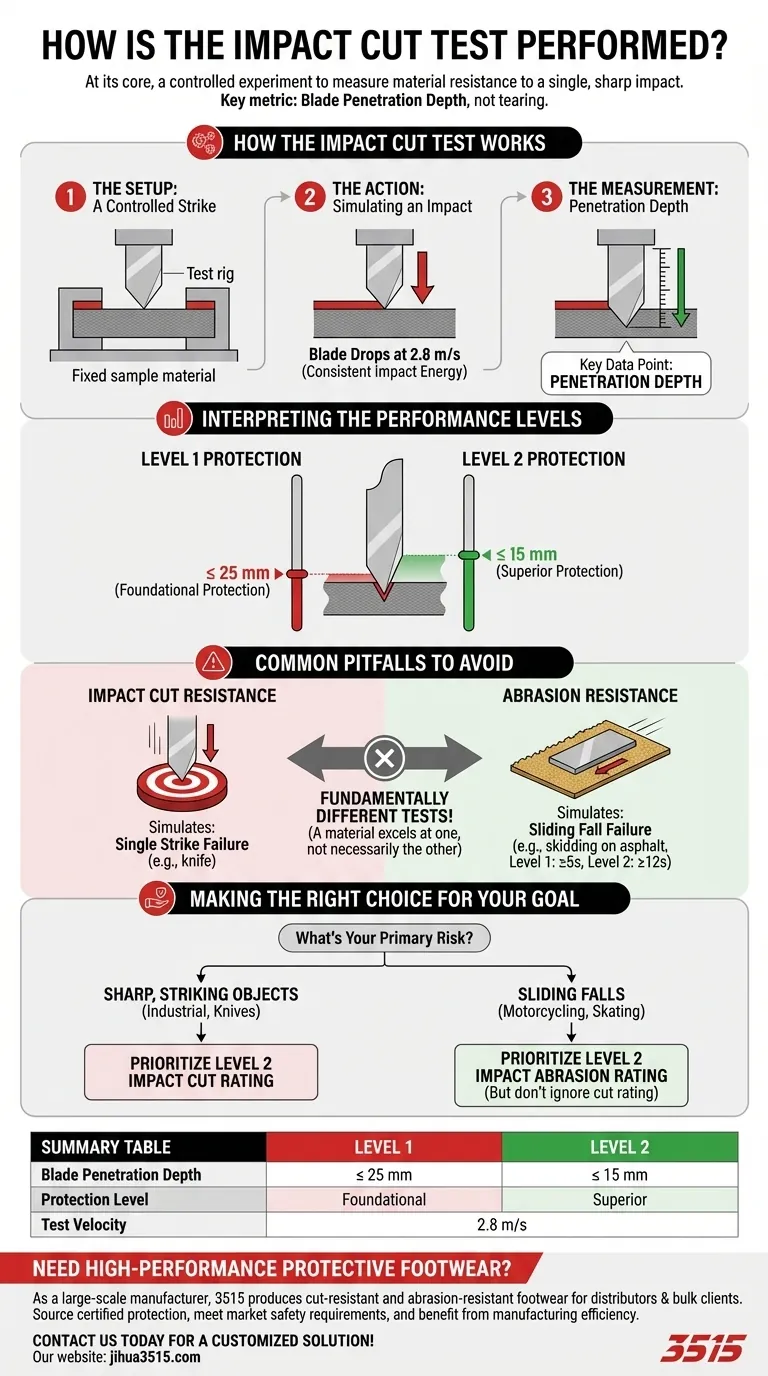

At its core, the impact cut test is a highly controlled experiment designed to measure a material's resistance to a single, sharp impact. A weighted blade is dropped from a set height onto a sample of the material, and the depth of the resulting cut determines its performance level.

This test simulates the real-world danger of a sharp object striking a protective material, where the key metric for safety is not how much the material tears, but how deeply the blade penetrates.

How the Impact Cut Test Works

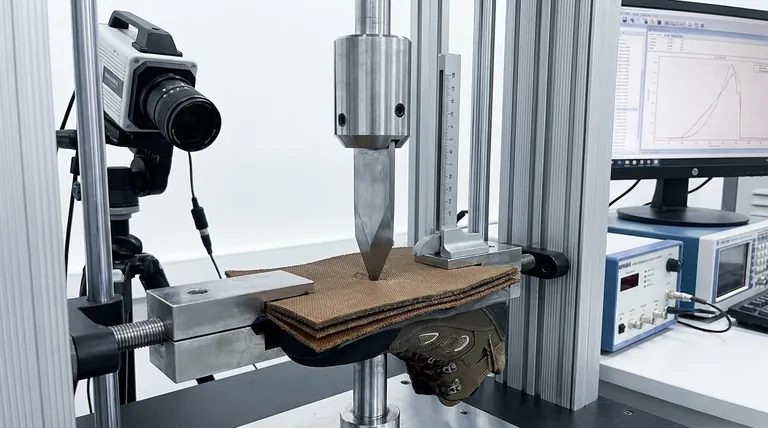

The procedure is standardized to ensure results are repeatable and comparable across different materials. It focuses on simulating a specific type of failure: a cut from a direct impact force.

The Setup: A Controlled Strike

A small sample of the test material is securely fixed in place. A sharp blade of a specified mass and geometry is positioned above it within a guided rig.

The Action: Simulating an Impact

The blade is dropped, accelerating to a precise velocity of 2.8 meters per second just before it strikes the material. This speed is critical for creating a consistent impact energy for every test.

The Measurement: Penetration Depth

After the strike, the key measurement is taken: the depth to which the blade penetrated the material sample. This single data point is the sole determinant of the material's rating in this test.

Interpreting the Performance Levels

The results are not graded on a curve but are compared against two absolute thresholds. These levels provide a clear and immediate understanding of the material's protective capabilities against this specific hazard.

Level 1 Protection

To achieve a Level 1 rating, the blade's penetration into the material must be less than or equal to 25 millimeters. This represents a foundational level of protection.

Level 2 Protection

Level 2 is a significantly higher standard of protection. To qualify, the blade's penetration must be less than or equal to 15 millimeters, indicating a superior resistance to the impact cut.

Common Pitfalls to Avoid

A common and critical mistake is to confuse impact cut resistance with abrasion resistance. They are fundamentally different tests that measure a material's ability to withstand two distinct types of damage.

Impact Cut vs. Impact Abrasion

The impact cut test uses a falling blade to simulate a single strike. In contrast, the impact abrasion test simulates a sliding fall, like skidding on asphalt. It does this by pressing the material against 60-grit sandpaper moving at 8 m/s and measuring how long it takes to wear through (Level 1: ≥5 seconds; Level 2: ≥12 seconds).

A Material's Dual Role

A material that excels at one test will not automatically excel at the other. For example, a rigid plate might easily stop a blade (high cut resistance) but could shatter or perform poorly during a long slide (low abrasion resistance). Conversely, a tough, leathery fabric might withstand abrasion well but be more easily punctured by a sharp blade.

Making the Right Choice for Your Goal

Understanding these distinct tests is crucial when selecting protective equipment, as the optimal choice depends entirely on the primary risks you face.

- If your primary focus is protection from sharp, striking objects (e.g., industrial work, knives): Prioritize a Level 2 rating in the impact cut test, as this directly measures the performance you need.

- If your primary focus is protection from sliding falls (e.g., motorcycling, skating): Prioritize a Level 2 rating in the impact abrasion test, but do not ignore the impact cut rating for comprehensive safety.

Ultimately, knowing what each test measures empowers you to choose the material that offers the most effective protection for your specific environment.

Summary Table:

| Aspect | Level 1 Protection | Level 2 Protection |

|---|---|---|

| Blade Penetration Depth | ≤ 25 mm | ≤ 15 mm |

| Protection Level | Foundational | Superior |

| Test Velocity | 2.8 m/s | 2.8 m/s |

Need High-Performance Protective Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of cut-resistant and abrasion-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet rigorous standards like the impact cut test.

We can help you:

- Source or develop footwear with certified impact cut protection.

- Ensure your products meet the specific safety requirements of your market.

- Benefit from our large-scale manufacturing efficiency and expertise.

Contact us today to discuss your protective footwear needs and receive a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management