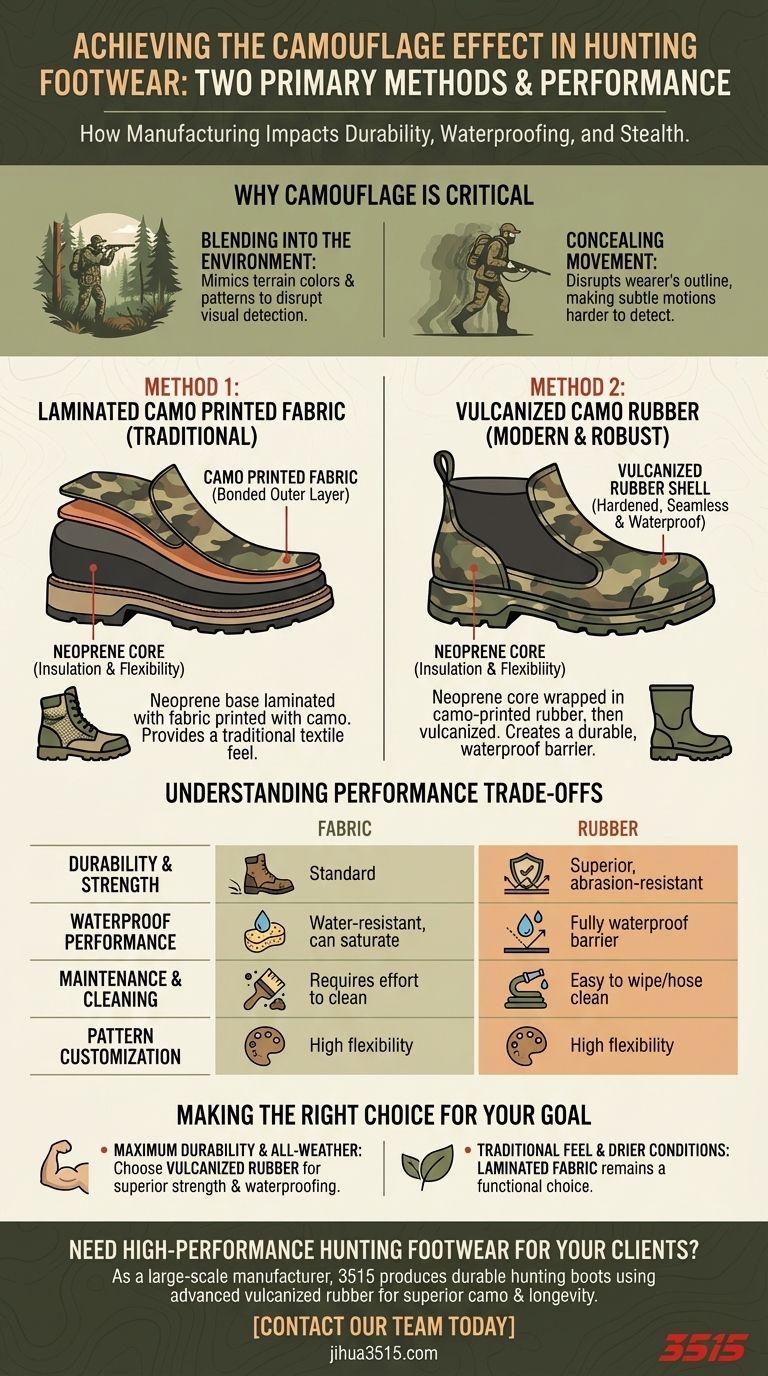

In hunting footwear, the camouflage effect is achieved through two primary manufacturing methods. The traditional approach involves laminating a neoprene base with a camouflage-printed fabric. A more modern and robust method involves wrapping the neoprene core with a pre-printed, vulcanized rubber shell that offers superior durability and weather resistance.

The core decision is not just about the camouflage pattern, but the material used to apply it. The choice between laminated fabric and vulcanized rubber directly impacts the boot's durability, waterproof performance, and ease of maintenance.

Why Camouflage is Critical in Hunting Footwear

The fundamental purpose of camouflage is to break up the wearer's outline and help them blend into the natural environment. This is essential for hunters who rely on stealth to get close to their game.

Blending into the Environment

Effective camouflage mimics the colors, tones, and patterns of the surrounding terrain, such as forests, marshes, or rocky landscapes. This visual disruption makes it significantly harder for animals with keen eyesight to distinguish the hunter from the background.

Concealing Movement

Even slight movements can alert game. By disrupting the clear outline of a foot and leg, camouflage makes it more difficult for animals to detect the subtle motions of a hunter stalking or waiting in a blind, preserving the element of surprise.

The Two Primary Methods of Camo Application

While the visual goal is the same, the way the pattern is applied to the boot's exterior dictates its real-world performance.

Method 1: Laminated Camo Printed Fabric

This is the classic technique. A layer of neoprene, which provides insulation and flexibility, is laminated (bonded) with an outer layer of fabric that has been printed with the desired camouflage pattern.

This method is well-established and produces a boot with a traditional textile feel.

Method 2: Vulcanized Camo Rubber

This more current method also uses a neoprene core. However, instead of fabric, the boot is wrapped with a sheet of specialized rubber that is printed with the camouflage pattern and then vulcanized.

Vulcanization is a chemical process that hardens the rubber, creating a seamless, durable, and completely waterproof outer shell.

Understanding the Performance Trade-offs

The choice between fabric and rubber goes far beyond aesthetics. It represents a clear trade-off in performance and longevity.

Durability and Strength

Vulcanized rubber is inherently more resistant to abrasions, scuffs, and punctures than fabric. This makes it a superior choice for navigating dense underbrush, rocky terrain, or any environment that is harsh on footwear.

Waterproof Performance

While the underlying neoprene offers water resistance, the vulcanized rubber shell creates a truly waterproof barrier. Fabric, on the other hand, can become saturated and may rely on a separate waterproof membrane that can be compromised over time.

Maintenance and Cleaning

A smooth rubber surface is significantly easier to clean. Mud, dirt, and other debris can be wiped or hosed off easily. Fabric surfaces can trap dirt in their weave, requiring more effort to clean and dry.

Pattern Customization

Both methods offer excellent flexibility for customization. Any digital camouflage pattern can be printed onto either the fabric or the rubber before it is applied to the boot, allowing for a wide variety of designs.

Making the Right Choice for Your Goal

Your selection should be guided by the conditions you expect to face and your performance priorities.

- If your primary focus is maximum durability and all-weather protection: Choose boots made with the vulcanized camouflage rubber method for their superior strength and waterproofing.

- If your primary focus is a traditional textile feel for less demanding or drier conditions: Boots using laminated camo fabric remain a functional and effective choice.

Ultimately, understanding how a boot is constructed empowers you to select footwear based on its performance capabilities, not just its pattern.

Summary Table:

| Method | Key Material | Durability | Waterproofing | Maintenance |

|---|---|---|---|---|

| Laminated Fabric | Camo-printed fabric bonded to neoprene | Standard | Water-resistant (can saturate) | Requires more effort to clean |

| Vulcanized Rubber | Camo-printed, hardened rubber shell | Superior, abrasion-resistant | Fully waterproof barrier | Easy to wipe or hose clean |

Need High-Performance Hunting Footwear for Your Clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable hunting boots using advanced methods like vulcanized rubber for superior camouflage, weather resistance, and longevity. We provide reliable, high-quality footwear solutions for distributors, brand owners, and bulk clients.

Contact our team today to discuss your specific needs and explore our production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- Why is weight (body + pack) important when choosing hunting boots? The Key to a Safe and Successful Hunt

- What factors were considered in testing gardening shoes? A Guide to Finding the Perfect Shoe for Your Garden

- How should hunting boot flexibility vary by season? Optimize Stealth and Support for Every Hunt

- What are hunt or top boots used for? The Ultimate Guide to Equestrian Tradition

- Are there hybrid boots that combine the benefits of snake and rubber boots? Stay Dry and Protected

- What are the key considerations when choosing motorcycle boots? Find Your Perfect Fit for Safety & Style

- What are dirt bike boots and how do they differ from ADV boots? Choose the Right Protection for Your Ride

- What are the design advantages of footwear engineered for high-density pedestrian environments? Optimized Urban Safety