The quality of a winter boot is the single most important predictor of its durability. High-quality boots are engineered systems, using superior materials and robust construction methods designed to resist constant exposure to moisture, abrasion, and structural stress. This directly translates into a much longer service life compared to cheaper alternatives, which often use materials and assembly techniques that fail at key stress points.

True durability isn't determined by a single feature; it's a result of how the boot's materials, construction, and design work together. A quality boot is built as a complete system to defend against its three primary enemies: water, abrasion, and stress.

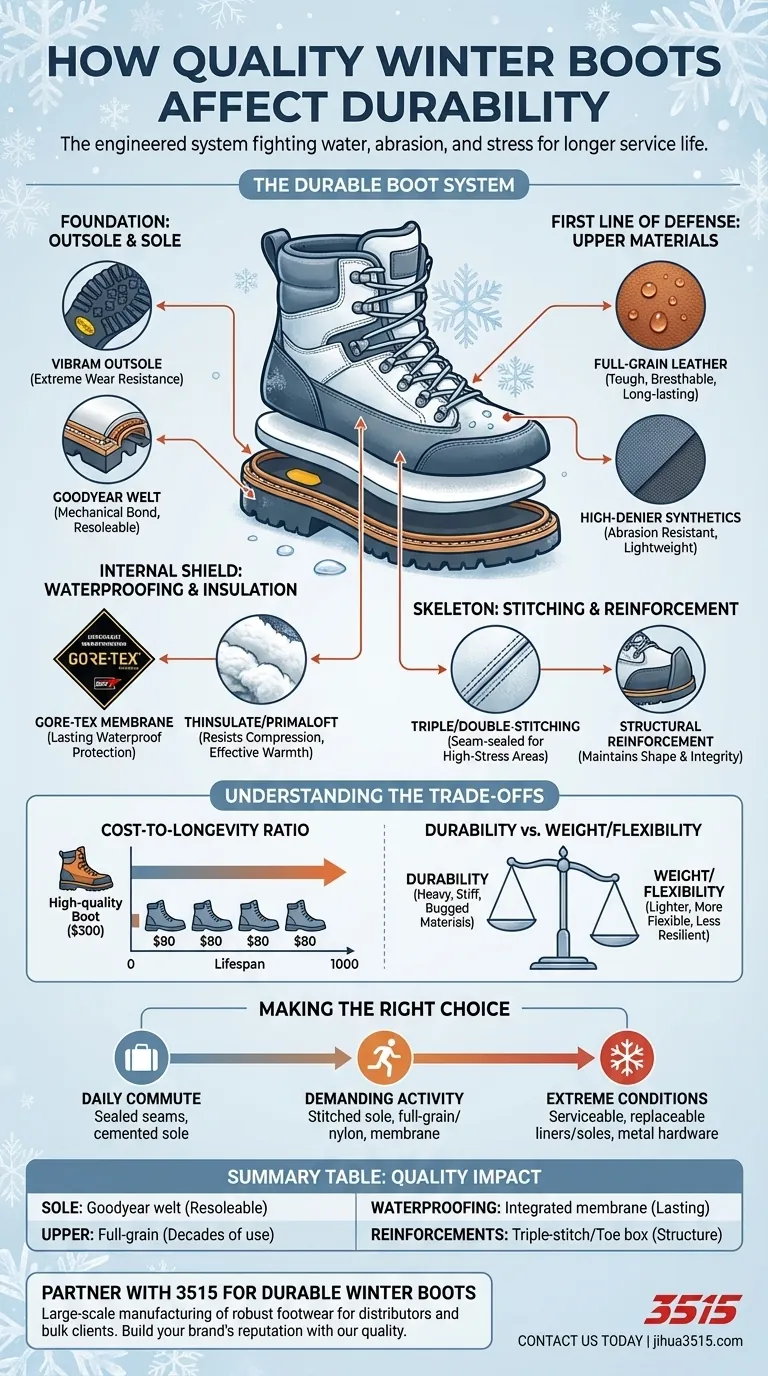

Deconstructing Quality: The Anatomy of a Durable Boot

To understand durability, you must look beyond brand names and price tags. Quality is found in the specific components and how they are assembled.

The Foundation: Outsole and Sole Construction

The outsole is the boot's point of contact with the world, enduring constant abrasion and impact. High-quality boots often use dense, proprietary rubber compounds from specialists like Vibram, which are engineered for grip and extreme wear resistance.

More importantly, look at how the sole is attached to the upper. A cemented construction (glued) is common and effective for lighter use. However, a Goodyear welt or similar stitched construction is the gold standard for durability, creating a mechanical bond that is far stronger and allows the boot to be resoled, dramatically extending its life.

The First Line of Defense: Upper Materials

The upper takes the brunt of scrapes, impacts, and moisture. The choice of material here is critical.

Full-grain leather is prized for its exceptional toughness, breathability, and ability to mold to your foot. It requires maintenance but can last for decades. High-denier synthetic fabrics, like Cordura nylon, offer excellent abrasion resistance at a lower weight.

Lower-quality boots often use split-grain leather or cheap, low-denier synthetics that degrade, crack, and tear much more quickly under stress.

The Internal Shield: Waterproofing and Insulation

A boot that leaks is a failed boot. Top-tier boots build in a waterproof, breathable membrane, such as a Gore-Tex bootie, between the outer material and the inner lining. This provides lasting waterproof protection that won't wear off.

Cheaper methods rely on a temporary water-repellent coating that quickly degrades. Likewise, quality insulation like Thinsulate or PrimaLoft resists compression, ensuring it continues to trap heat effectively season after season.

The Skeleton: Stitching and Reinforcement

Durability is often found in the details. Look for triple- or double-stitching in high-stress areas like the heel and forefoot. Seam-sealing, where seams are coated with waterproof sealant, is another hallmark of a well-made boot.

Finally, a quality boot features structural reinforcements. A rigid heel counter and a reinforced toe box not only protect your foot but also help the boot maintain its shape and structural integrity over years of use.

Understanding the Trade-offs

Choosing a winter boot involves balancing competing factors. A truly durable boot is the result of deliberate engineering choices.

The Cost-to-Longevity Ratio

A high-quality boot has a significantly higher upfront cost. However, this is an investment in longevity. You might buy one pair of $300 boots that lasts a decade, or five pairs of $80 boots over the same period.

If the high-end boot is resoleable, its potential lifespan is even longer, making it the more economical choice over the long term.

Durability vs. Weight and Flexibility

There is often a direct trade-off between absolute durability and comfort. The most rugged materials and construction methods—like thick leather, stiff soles, and extensive reinforcements—result in a heavier, stiffer boot.

For casual daily wear, this level of durability can be overkill. A lighter, more flexible boot may be more comfortable, but you sacrifice some resilience to achieve it.

The Myth of the "Indestructible" Boot

No boot lasts forever without care. Durability is a partnership between the manufacturer's quality and the owner's maintenance.

Regularly cleaning off salt and dirt, conditioning leather uppers, and properly drying the boots after use are essential to realizing their maximum potential lifespan.

Making the Right Choice for Your Goal

Select a boot that aligns with the intensity and frequency of your intended use.

- If your primary focus is daily commuting in moderate winter conditions: A boot with sealed seams and a quality cemented sole provides an excellent balance of durability, comfort, and value.

- If your primary focus is frequent, demanding outdoor activity like hiking or heavy work: Prioritize a stitched sole construction (like a Goodyear welt), full-grain leather or high-denier nylon uppers, and a reputable waterproof membrane.

- If your primary focus is extreme conditions and longevity above all else: Invest in boots with features designed for serviceability, such as replaceable liners and soles, and robust metal hardware for lacing.

Ultimately, investing in quality is about securing reliability and performance when you need it most.

Summary Table:

| Quality Factor | Impact on Durability |

|---|---|

| Sole Construction | Goodyear welt allows for resoling; cemented is less durable. |

| Upper Material | Full-grain leather offers decades of use; synthetics vary. |

| Waterproofing | Integrated membranes (e.g., Gore-Tex) last; coatings wear off. |

| Reinforcements | Double/triple stitching & toe boxes maintain boot structure. |

Partner with 3515 for Durable Winter Boots That Build Your Brand's Reputation

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities, from robust Goodyear welt construction to high-grade material selection, ensure the boots you sell are built to last, enhancing customer satisfaction and repeat business.

Contact us today to discuss your manufacturing needs and how we can deliver reliable, high-quality winter boots for your market.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes