To put it directly, the new boot integrates a specialized ballistic fabric-like layer under the sole to achieve its puncture resistance. This modern material is specifically engineered to stop sharp foreign objects from penetrating the footwear and injuring the foot, a design tailored for specific environmental hazards.

The core innovation is the shift from traditional rigid metal plates to a flexible, high-strength fabric. This provides targeted protection against environmental threats like sharpened sticks while significantly enhancing user mobility and comfort.

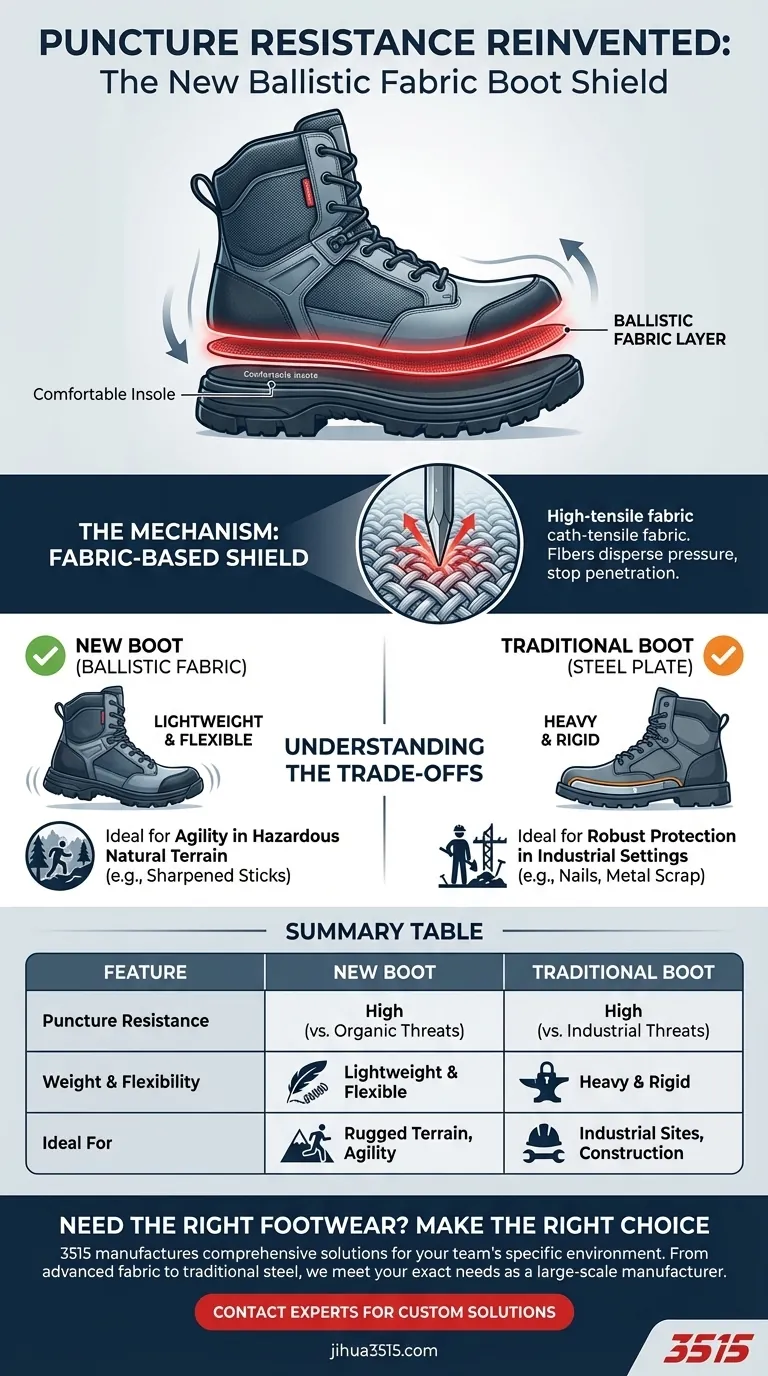

The Mechanism of Protection: A Fabric-Based Shield

The boot's design represents a modern approach to foot protection. It moves beyond the classic methods seen in many work boots to address a unique set of challenges.

The Ballistic Fabric Layer

Positioned between the boot's outsole and insole is a layer of tightly woven, high-tensile fabric. This material is similar in principle to fabrics used in body armor, though engineered specifically for footwear.

How It Defeats Punctures

When a sharp object attempts to penetrate the sole, the force is met by the fabric's extremely strong fibers. These fibers catch the tip of the object and disperse the pressure across a wider surface area, preventing it from passing through to the foot.

Designed for a Specific Threat

This technology was developed with environmental hazards in mind, such as the punji sticks still found in some jungle environments. The design is optimized to counter sharp, organic materials encountered in rugged, off-trail terrain.

A Comparison with Traditional Methods

Understanding this new system requires comparing it to the industry standard for puncture-resistant footwear.

The Standard: Steel Plates

For decades, the most common form of puncture resistance has been a thin steel plate embedded in the boot's sole. This method provides a rigid, impenetrable barrier against a wide array of sharp objects.

Fabric vs. Metal

While a steel plate is highly effective, it adds significant weight and rigidity to the boot, which can impede natural foot movement and cause fatigue. The ballistic fabric offers a lightweight and flexible alternative, allowing the boot to bend and move more naturally with the foot.

Understanding the Trade-offs

No single design is perfect for every scenario. The choice between a fabric layer and a metal plate involves clear trade-offs in performance and application.

Flexibility and Mobility

The primary advantage of the ballistic fabric is flexibility. For users who need to move quickly and quietly through uneven terrain, this feature is critical. It allows for a more natural stride and reduces the energy required for each step.

Type of Protection

The fabric is highly effective against the specific threats it was designed for. However, a solid steel plate may offer more robust protection in an industrial setting, where threats include fine nails, sharp metal scrap, or heavy-duty construction debris.

Scope of Protection

It is important to note this feature specifically protects the bottom of the foot from punctures through the sole. Overall foot safety also depends on other elements, such as a reinforced or steel toe cap, which protects against impacts and punctures to the front of the boot.

Making the Right Choice for Your Environment

Your specific operational environment should dictate your choice of protective footwear. The goal is to match the technology to the most likely threat.

- If your primary focus is agility in hazardous natural terrain: The new boot's flexible ballistic fabric offers excellent protection against environmental threats without compromising mobility.

- If your primary focus is safety on a construction or industrial site: A boot featuring a traditional steel plate may provide more appropriate protection against nails and metal scrap.

Ultimately, understanding the specific technology allows you to select the precise tool required for your mission.

Summary Table:

| Feature | New Boot (Ballistic Fabric) | Traditional Boot (Steel Plate) |

|---|---|---|

| Puncture Resistance | High (vs. organic threats) | High (vs. industrial threats) |

| Weight & Flexibility | Lightweight & Flexible | Heavy & Rigid |

| Ideal For | Rugged terrain, agility-focused tasks | Industrial sites, construction debris |

Need the right protective footwear for your team's specific environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your priority is agile movement in natural terrain with our advanced fabric technology or robust protection in industrial settings with traditional steel plates, we have the production capabilities to meet your exact needs.

Contact our experts today to discuss custom solutions for your operational challenges.

Visual Guide

Related Products

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What is the significance of providing standardized steel-toed safety shoes? Enhance Occupational Health Research Accuracy

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- How does the flexibility design of industrial safety shoes assist shipyard electricians? Boost Agility & Back Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort