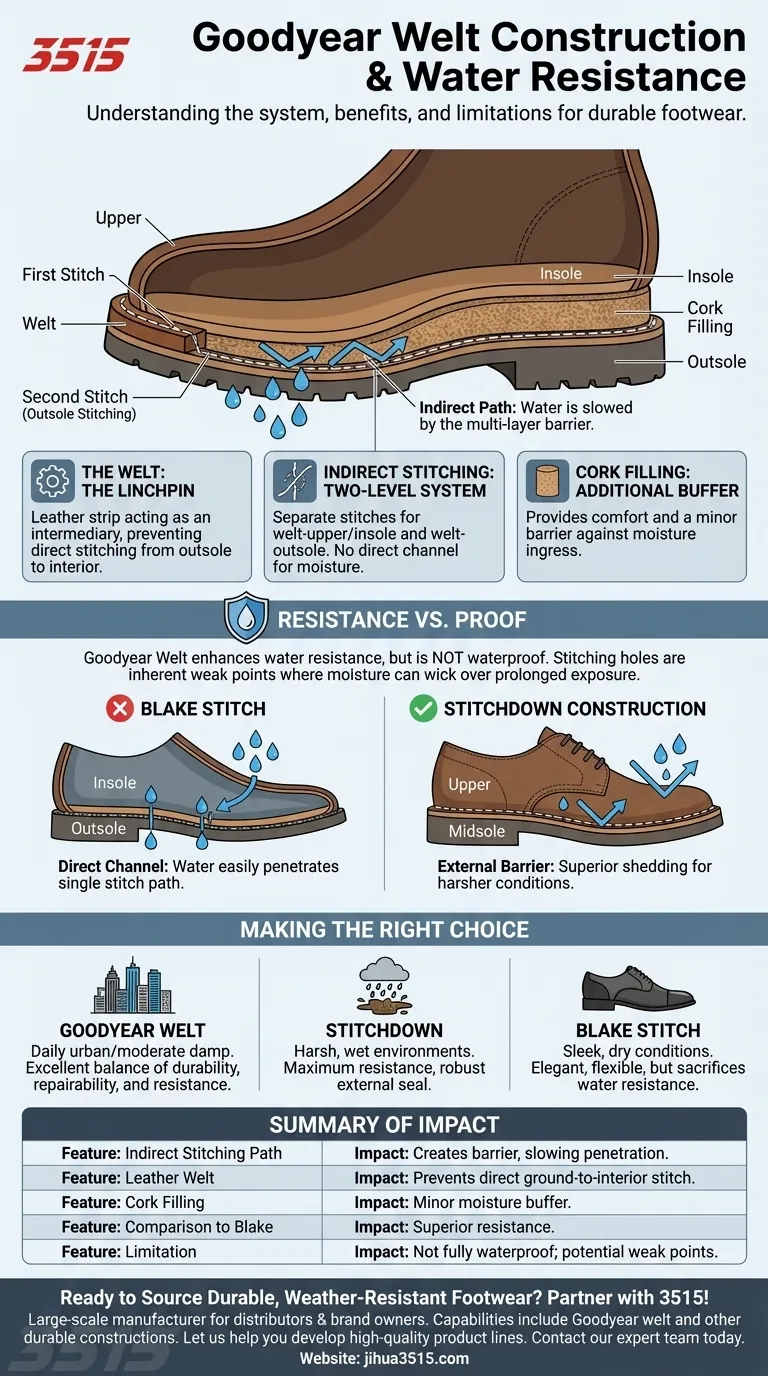

To be clear, Goodyear welt construction enhances water resistance but does not make a shoe waterproof. The key is its design, which stitches a leather strip (the welt) to the shoe's upper and insole, and then stitches that welt to the outsole. This creates a multi-layered barrier and places the primary stitching on the exterior of the shoe, rather than creating a direct channel from the wet ground to the insole.

The core principle is that a Goodyear welt creates a more complex and indirect path for water to travel. By avoiding a direct stitch between the outsole and the insole, it significantly slows down water penetration compared to simpler construction methods, but it's not a truly sealed system.

Unpacking the Construction: How the Layers Work

A shoe's resistance to water isn't about a single feature; it's about the system of construction. The Goodyear welt is a foundational part of that system.

The Role of the Welt

The welt is a strip of leather sewn around the perimeter of the upper. This single component is the linchpin of the construction's water resistance. It acts as an intermediary, preventing the outsole from being stitched directly into the interior of the shoe.

An Indirect Stitching Path

In a Goodyear welt, there are two independent sets of stitches. The first attaches the welt to the upper and insole. The second, completely separate stitch attaches the welt to the outsole.

This two-level stitching system is crucial. It means the holes created by the outsole stitching do not pass through to the inside of the shoe, which is a common entry point for moisture in other methods like Blake stitching.

The Cork-Filled Cavity

The space created between the insole and outsole by the welt is typically filled with a layer of cork. While primarily for comfort and molding to your foot, this cork layer provides an additional, minor buffer against moisture that might find its way past the outsole stitching.

Understanding the Trade-offs: Resistance vs. Proof

It's critical to distinguish between water resistance and being waterproof. The Goodyear welt method introduces its own set of vulnerabilities that prevent it from being a fully waterproof solution.

Stitching Holes are Inherent Weak Points

Any time you punch a hole in leather with a needle and thread, you create a potential point of entry for water. While the welt's design minimizes this risk, the stitches themselves can still wick moisture over time, especially during prolonged exposure to wet conditions.

Comparison to Other Methods

The limitations of a Goodyear welt are best understood by comparing it to other constructions. In a Blake stitch, the outsole is stitched directly to the insole, creating a clear and direct path for water to enter the shoe.

Conversely, Stitchdown construction, often used in heavy-duty work boots, folds the upper outward and stitches it directly to the midsole. This design creates a highly effective external barrier that sheds water away from the seams, often making it superior to a Goodyear welt for pure water resistance.

Making the Right Choice for Your Goal

Selecting the right shoe construction depends entirely on your intended use and environment.

- If your primary focus is daily wear in urban or moderately damp conditions: A Goodyear welt offers an excellent balance of durability, repairability, and sufficient water resistance to handle puddles and rain.

- If your primary focus is maximum water resistance for harsh, wet environments: Look for Stitchdown construction combined with water-resistant leathers, as this method provides a more robust seal against the elements.

- If your primary focus is a sleek, flexible dress shoe for dry conditions: A Blake-stitched shoe is often preferred, as its simpler construction allows for a closer-trimmed, more elegant sole, though it sacrifices significant water resistance.

Ultimately, the Goodyear welt is a proven method for building a durable and weather-capable shoe, but understanding its specific strengths and limitations is key to a wise investment.

Summary Table:

| Feature | Impact on Water Resistance |

|---|---|

| Indirect Stitching Path | Creates a barrier, slowing water penetration from the outsole to the insole. |

| Leather Welt | Acts as an intermediary strip, preventing a direct stitch from the ground to the shoe's interior. |

| Cork Filling | Provides a minor moisture buffer in the cavity between the insole and outsole. |

| Comparison to Blake Stitch | Superior resistance as it avoids a direct channel for water entry. |

| Limitation | Not fully waterproof; stitching holes remain potential weak points during prolonged exposure. |

Ready to Source Durable, Weather-Resistant Footwear? Partner with 3515!

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those built with durable constructions like the Goodyear welt.

We can help you develop a product line that balances durability, comfort, and weather resistance for your target market.

Contact our expert team today to discuss your manufacturing needs and bring high-quality footwear to your customers.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort