In short, Cordura's performance is a direct function of its weight and weave. Heavier, denser fabrics like 1000D offer maximum abrasion resistance for industrial and tactical applications, while lighter weights like 500D provide a more flexible, balanced durability ideal for everyday gear and apparel. The specific style determines its resistance to tears, water, and even flames.

The key to selecting the right Cordura isn't simply choosing the heaviest option; it's about matching the fabric's specific denier (weight) and construction to your precise needs, balancing extreme durability against weight, flexibility, and feel.

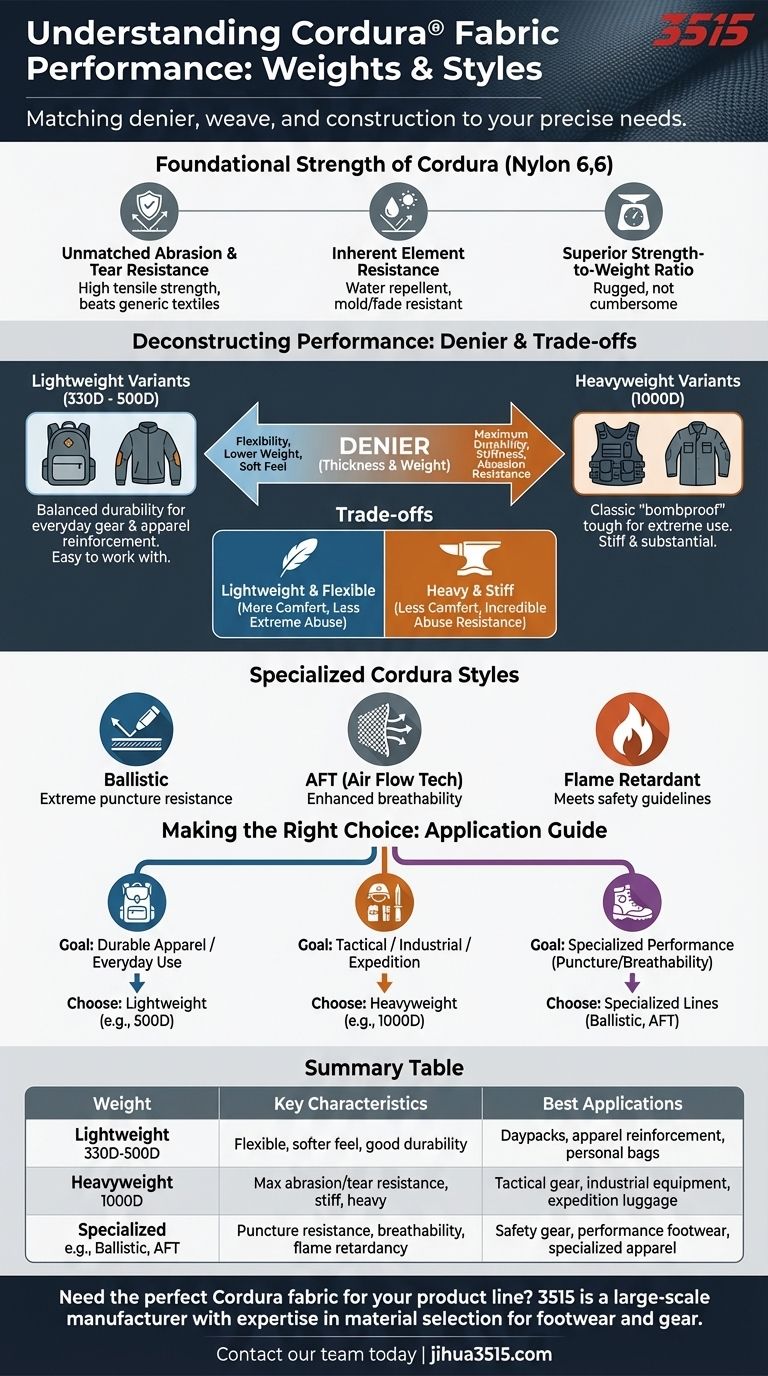

The Foundational Strength of Cordura

Before comparing different types, it's crucial to understand what makes all Cordura fabric a benchmark for durability. Its performance comes from using high-tenacity nylon 6,6 fiber technology.

Unmatched Abrasion and Tear Resistance

All Cordura variants are engineered for high tensile strength, giving them exceptional resistance to long-term wear, scuffs, and abrasions. Compared to other common materials, it is significantly more durable than standard polyester and nylon fabrics.

Inherent Element Resistance

The fabric is naturally water-repellent, causing moisture to bead up and roll off. It is also highly resistant to performance degradation from mold, mildew, and fading due to sun exposure, making it ideal for outdoor equipment.

Superior Strength-to-Weight Ratio

One of Cordura's most valued characteristics is its impressive durability relative to its weight. This allows for the creation of rugged products that are not excessively heavy or cumbersome.

Deconstructing Cordura: Weight, Denier, and Style

The primary differentiator in Cordura's performance is its "denier," a unit of measurement for the thickness and weight of the fiber. A higher denier number indicates a heavier, thicker, and generally more rugged fabric.

Lightweight Variants (e.g., 330D - 500D)

These fabrics prioritize flexibility and reduced weight while still offering durability far superior to generic textiles. They are soft to the touch and easy to work with.

This range is the standard for high-quality daypacks, apparel reinforcement (on knees or shoulders), and personal bags where a balance of toughness and comfort is essential.

Heavyweight Variants (e.g., 1000D)

This is the classic, "bombproof" Cordura that built the brand's reputation. A typical weight is around 11 ounces per square yard, making it a substantial and incredibly tough material.

Its primary application is in environments where failure is not an option. Think military-grade bags, heavy-duty industrial covers, and luggage designed for extreme use. The texture is stiffer and more abrasive than its lighter-weight counterparts.

Specialized Cordura Styles

Beyond standard weaves, Cordura offers specialized lines for specific performance needs. This includes Ballistic nylon for extreme puncture resistance and AFT (Air Flow Technology) fabrics, which offer enhanced breathability for footwear and apparel. Some variants are also treated to be flame-retardant, meeting strict safety guidelines.

Understanding the Trade-offs

Choosing the right Cordura requires acknowledging that every benefit comes with a corresponding compromise. An expert decision involves weighing these factors against your goal.

Durability vs. Weight and Flexibility

This is the most significant trade-off. While 1000D Cordura can withstand incredible abuse, it is also heavy and stiff. A 500D Cordura bag will be significantly lighter and more pliable, but it won't endure the same level of punishment as its heavier counterpart.

Breathability Considerations

While Cordura offers some breathability, heavier and more densely woven versions will inherently restrict airflow more than lighter ones. Additional coatings for water- or flame-resistance will further reduce this property.

Texture and Comfort

The ruggedness of heavyweight Cordura comes with a coarse texture. For items that will have direct, prolonged contact with skin, a lighter denier fabric is almost always the more comfortable choice.

Making the Right Choice for Your Application

Use your primary goal to guide your selection.

- If your primary focus is durable apparel or an everyday-use backpack: A lighter weight like 500D offers the ideal blend of excellent durability, flexibility, and manageable weight.

- If your primary focus is maximum toughness for tactical, industrial, or expedition gear: A heavyweight 1000D fabric provides the uncompromising abrasion and tear resistance required for harsh environments.

- If your primary focus is specialized performance like puncture resistance or breathability: Look beyond standard denier and investigate specialized lines like Cordura Ballistic or AFT.

By understanding these core principles, you can select a Cordura fabric that performs precisely as your mission demands.

Summary Table:

| Cordura Weight | Key Characteristics | Best Applications |

|---|---|---|

| Lightweight (330D-500D) | Flexible, softer feel, good durability | Daypacks, apparel reinforcement, personal bags |

| Heavyweight (1000D) | Maximum abrasion/tear resistance, stiff, heavy | Tactical gear, industrial equipment, expedition luggage |

| Specialized (e.g., Ballistic, AFT) | Puncture resistance, breathability, flame retardancy | Safety gear, performance footwear, specialized apparel |

Need the perfect Cordura fabric for your product line? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and gear for distributors, brand owners, and bulk clients. Our expertise in material selection ensures your products meet the exact balance of durability, weight, and performance your customers demand. Contact our team today to discuss your specific needs and get a custom solution.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

People Also Ask

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability