At its core, the difference between a Western work boot and a traditional Western boot comes down to a single principle: purpose. One is a specialized tool designed for working safely and comfortably on your feet all day, while the other is engineered specifically for the unique demands of riding a horse. Every design element, from the heel to the toe, reflects this fundamental distinction.

While they may share a silhouette, Western work boots are built from the ground up for stability, traction, and safety on foot. Traditional cowboy boots, in contrast, are purpose-built for the saddle, prioritizing features that enhance a rider's connection and safety with the stirrup.

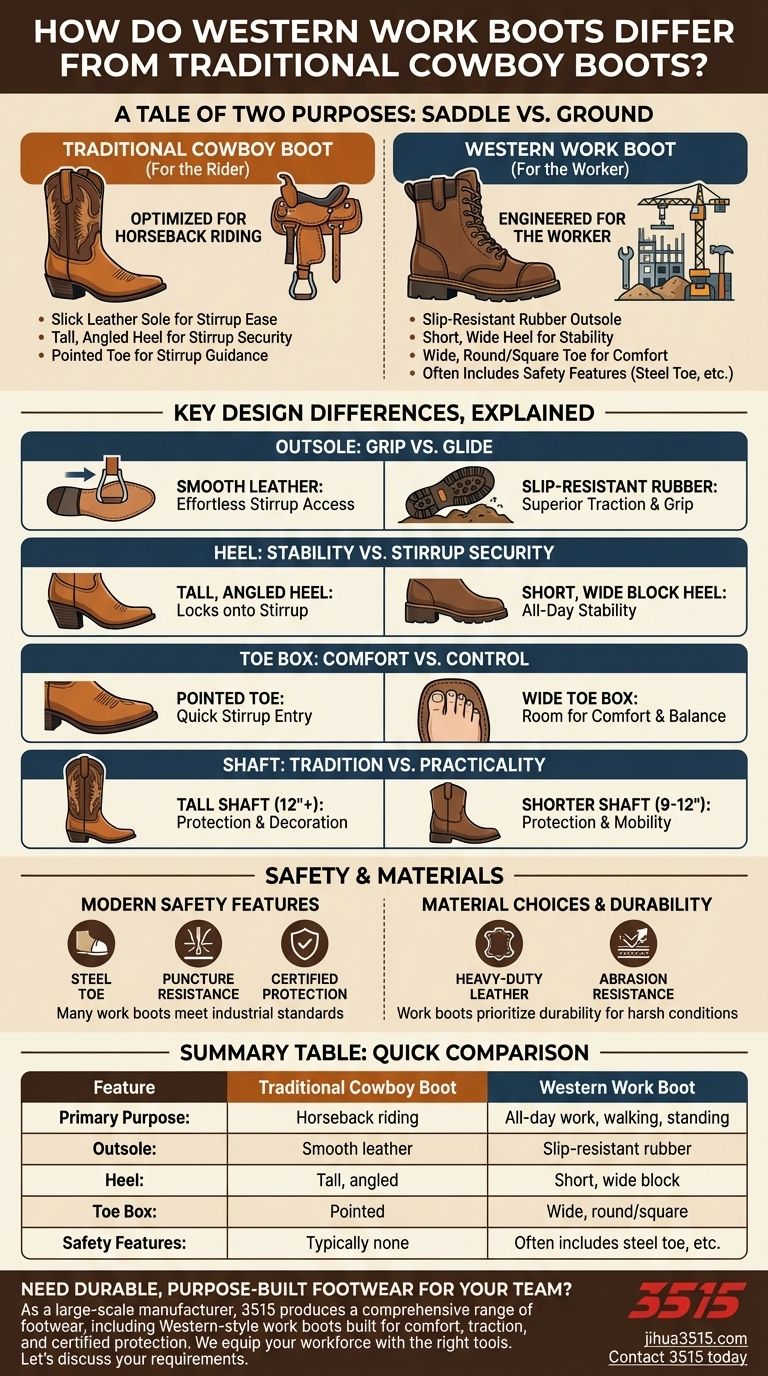

A Tale of Two Purposes: The Saddle vs. The Ground

The visual similarities between these boots can be misleading. Their designs evolved to solve two very different problems, resulting in critical functional differences.

The Traditional Cowboy Boot: A Tool for the Rider

A traditional cowboy boot is optimized for horseback riding. Its features are a direct response to the needs of a rider in a Western saddle.

The slick leather sole and pointed toe allow the boot to slide easily into and out of a stirrup, which is a crucial safety feature. The tall, angled heel is designed to catch the back of the stirrup, preventing the foot from sliding too far forward and getting dangerously stuck.

The Western Work Boot: Engineered for the Worker

The Western work boot, often called a roper or rancher boot, is designed for long hours of walking, standing, and labor. It sacrifices riding-specific features in favor of comfort, stability, and safety on the ground.

Its design prioritizes all-day wearability for tasks ranging from ranch duties to industrial job site work.

Key Design Differences, Explained

Function dictates form. Examining the four key components of the boot reveals how each is tailored to its intended environment.

The Outsole: Grip vs. Glide

A traditional cowboy boot features a smooth leather outsole. This is intentional, as it allows the boot to glide effortlessly into and out of a stirrup without catching.

A Western work boot has a slip-resistant rubber outsole, often with an aggressive tread pattern. This provides superior traction and grip on varied and uneven surfaces, a critical feature for workplace safety.

The Heel: Stability vs. Stirrup Security

Cowboy boots have a tall, angled "Cuban" heel, typically over an inch high. Its primary function is to lock onto the back of a stirrup, providing a secure anchor for the rider.

Work boots feature a short, wide block heel, often called a "roper" heel, which is usually a half-inch high and straight. This lower, broader base provides significantly more stability for walking and standing, reducing fatigue over a long day.

The Toe Box: Comfort vs. Control

The classic cowboy boot has a pointed toe. This design helps guide the rider's foot into the stirrup quickly and efficiently.

Western work boots use a much wider round or square toe box. This gives the toes more room to spread out, which is essential for comfort and balance when walking or standing for extended periods.

The Shaft: Tradition vs. Practicality

Traditional cowboy boots often have a tall shaft, typically 12 inches or more, which offers protection from brush and can be highly decorative.

Western work boots generally have a shorter shaft, from 9 to 12 inches. This provides adequate protection while allowing for greater flexibility and ease of movement for on-foot labor.

Understanding the Trade-offs: Safety and Materials

Beyond the core design, the choice of materials and inclusion of modern safety features create a clear line between the two styles.

The Role of Modern Safety Features

Many Western work boots are built to meet industrial job site standards. They frequently include steel toes, puncture-resistant plates, and other certified safety components that are absent in traditional cowboy boots.

Material Choices and Durability

While both boots use leather, traditional cowboy boots may feature polished or exotic leathers chosen for style and cultural identity. Work boots prioritize heavy-duty, durable materials designed to withstand harsh conditions, chemicals, and abrasion.

Making the Right Choice for Your Needs

Selecting the right boot requires a clear understanding of your primary activity.

- If your primary focus is horseback riding: A traditional cowboy boot with its smooth sole and angled heel is the correct and safer tool for the job.

- If your primary focus is all-day labor, walking, or ranch work: A Western work boot will provide the necessary comfort, traction, and stability.

- If you need certified protection for an industrial job site: You must choose a Western work boot that is explicitly rated for safety standards like steel toe or electrical hazard resistance.

Ultimately, choosing the right boot is about matching its purpose-built design to your daily demands.

Summary Table:

| Feature | Traditional Cowboy Boot | Western Work Boot |

|---|---|---|

| Primary Purpose | Horseback riding | All-day work, walking, standing |

| Outsole | Smooth leather for easy stirrup access | Slip-resistant rubber for traction |

| Heel | Tall, angled 'Cuban' heel for stirrup security | Short, wide 'roper' heel for stability |

| Toe Box | Pointed for stirrup guidance | Wide, round/square for comfort |

| Safety Features | Typically none | Often includes steel toe, puncture-resistant plates |

Need Durable, Purpose-Built Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, including Western-style work boots built for comfort, traction, and certified protection.

We help you equip your workforce with the right tools for the job, ensuring safety and reducing fatigue. Let's discuss your specific requirements and how our manufacturing expertise can deliver the quality and volume you need.

Contact 3515 today for a consultation and to request a quote.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why is it important to waterproof leather work boots? Protect Your Investment and Performance

- How are engineer boots typically styled? Master the Rugged, Timeless Look

- What safety features are critical for electrical work boots? Choose the Right Protection for Your Job

- What should be done before wearing new work boots for the first time? A 3-Step Guide for Optimal Fit & Durability

- What features should roofers look for in work boots? Essential Safety and Comfort for the Job

- Which occupations typically prefer composite toe boots? Lightweight, Non-Conductive Safety for Electricians & Engineers

- What are the potential drawbacks of pull-on work boots? Limited Ankle Support & Fit Issues

- What advantages do 8 inch boots offer over 6 inch boots? Superior Ankle Support & Protection