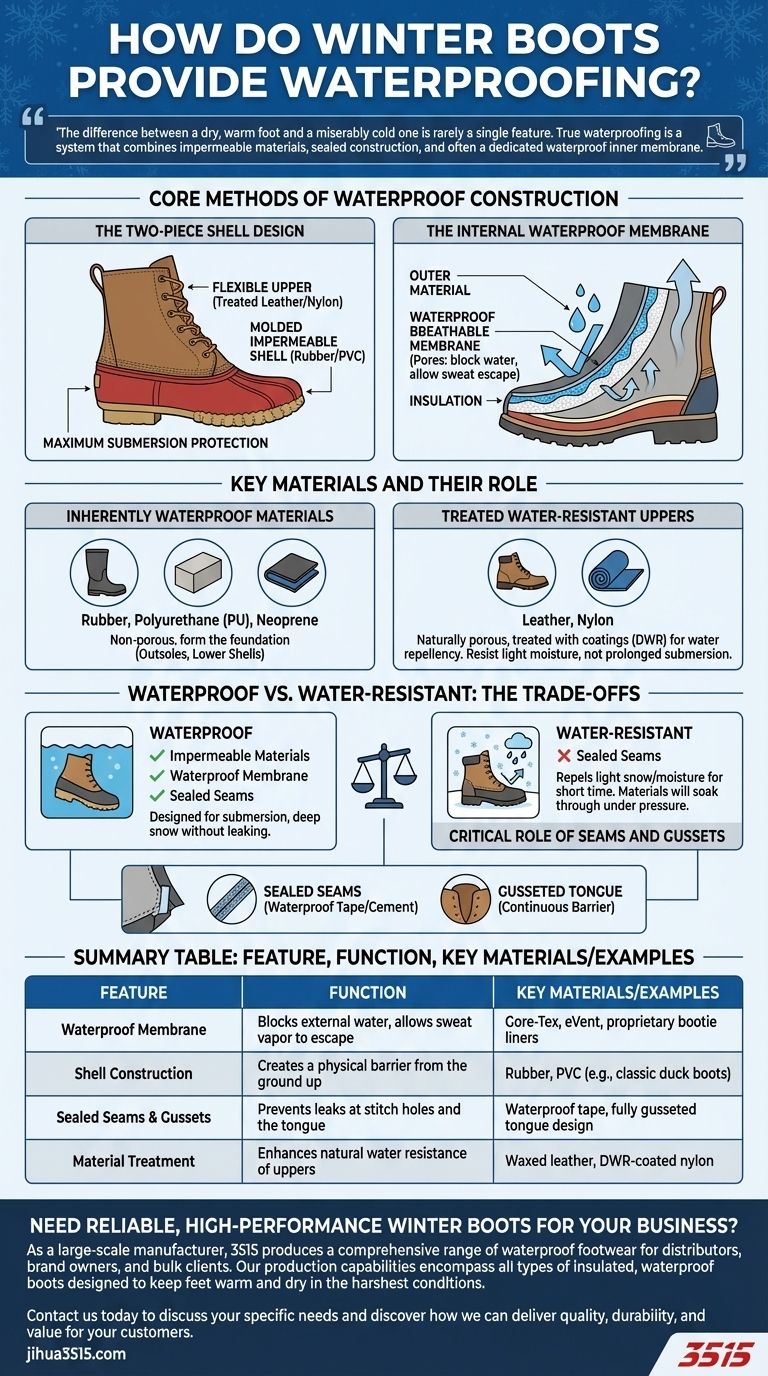

Winter boots achieve waterproofing through two primary strategies: using inherently impermeable materials like rubber to build a physical barrier, or integrating a waterproof, breathable membrane into the boot’s construction. This core design is reinforced by critical details like sealed seams and gusseted tongues to prevent moisture from seeping through weak points.

The difference between a dry, warm foot and a miserably cold one is rarely a single feature. True waterproofing is a system that combines impermeable materials, sealed construction, and often a dedicated waterproof inner membrane.

The Core Methods of Waterproof Construction

A boot's ability to keep water out is determined by its fundamental design. Most waterproof winter boots rely on one of two proven construction methods.

The Two-Piece Shell Design

This is a classic and highly effective approach, often seen in "duck boot" styles. It involves creating a lower section, or shell, from a single piece of molded, non-porous material like rubber or PVC.

This lower shell is then stitched to a more flexible upper made from materials like treated leather or nylon. This design provides maximum, failsafe protection for the part of your foot most likely to be submerged in snow or slush.

The Internal Waterproof Membrane

This modern technique places a waterproof and breathable liner, often shaped like a sock or "bootie," between the boot's outer material and its inner insulation.

This membrane contains microscopic pores that are too small for water droplets to pass through from the outside, but large enough for water vapor (sweat) to escape from the inside. This keeps your feet dry from both external moisture and internal perspiration.

Key Materials and Their Role

The materials chosen for a boot are the first line of defense against the elements. They fall into two distinct categories.

Inherently Waterproof Materials

These materials are non-porous and do not allow water to penetrate their structure. They form the foundation of any truly waterproof boot.

Common examples include rubber, polyurethane (PU), and neoprene. They are most often used for outsoles and the lower protective shells of boots.

Treated Water-Resistant Uppers

Materials like leather and nylon are naturally porous but are valued for their durability and flexibility. To be used in winter boots, they must be treated with coatings to repel water.

While these materials can fend off light moisture, they are best described as water-resistant. They will eventually become saturated if exposed to wet conditions for a prolonged period unless they are backed by a waterproof membrane.

Understanding the Trade-offs: Waterproof vs. Water-Resistant

Marketing terms can be confusing, but the distinction between "waterproof" and "water-resistant" is critical for performance.

Defining "Waterproof"

A truly waterproof boot is designed to be submerged in water or deep snow up to a certain height without leaking. This level of protection is only possible when the design includes impermeable materials, a waterproof membrane, and sealed seams.

Defining "Water-Resistant"

A water-resistant boot can repel light snow and resist moisture for a short time. However, its seams are typically not sealed, and its materials will eventually soak through under sustained pressure or exposure.

The Critical Role of Seams and Gussets

A boot is only as waterproof as its weakest point. Even the best materials will fail if the seams where they are joined together are not sealed with waterproof tape or cement.

Similarly, look for a gusseted tongue—one that is connected to the uppers along the sides. This feature creates a continuous barrier that prevents water and debris from entering through the lace area.

Making the Right Choice for Your Needs

To choose the right boot, align its waterproof technology with your intended use.

- If your primary focus is maximum protection in deep snow and slush: Look for boots with a high rubber shell or a certified waterproof membrane and a fully gusseted tongue.

- If your primary focus is casual wear in light snow or cold, dry conditions: A water-resistant boot with treated leather or nylon uppers may be sufficient and often provides more style flexibility.

- If your primary focus is maintaining your current boots: Regularly clean them and apply the correct waterproofing treatment (wax, spray, or oil) for the specific material to preserve its water repellency.

Understanding how a boot is constructed is the key to ensuring your feet remain warm and dry in any winter condition.

Summary Table:

| Feature | Function | Key Materials/Examples |

|---|---|---|

| Waterproof Membrane | Blocks external water, allows sweat vapor to escape | Gore-Tex, eVent, proprietary bootie liners |

| Shell Construction | Creates a physical barrier from the ground up | Rubber, PVC (e.g., classic duck boots) |

| Sealed Seams & Gussets | Prevents leaks at stitch holes and the tongue | Waterproof tape, fully gusseted tongue design |

| Material Treatment | Enhances natural water resistance of uppers | Waxed leather, DWR-coated nylon |

Need Reliable, High-Performance Winter Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated, waterproof boots designed to keep feet warm and dry in the harshest conditions.

Contact us today to discuss your specific needs and discover how we can deliver quality, durability, and value for your customers.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why must insole materials exhibit high resilience and anti-deformation properties? Essential for Heavy-Load Safety

- What are the best cowboy boot shapes for wide feet? Find Your Perfect, Comfortable Fit

- What concerns are raised about using boots? Managing Heat and Pressure Risks for Horse Legs

- What are the advantages of bovine leather for cowboy boots? The Ultimate Guide to Durability & Comfort

- Why are capacitive thin-film pressure sensor arrays preferred for smart footwear R&D? High-Precision Data Solutions

- What is cement construction in footwear, and what are its limitations? A Guide to Modern Shoe Manufacturing

- How does foot care routine impact standing workers? Prevent Pain & Boost Productivity

- Why might Goretex be ineffective in boots? The Hidden System Flaw That Traps Moisture