At first glance, Western boots and work boots share a rugged aesthetic, but their core designs are engineered for fundamentally different environments: the saddle versus the job site. A traditional Western boot is a specialized tool for horseback riding, featuring a high, angled heel and smooth leather sole for stirrup control. A work boot is a piece of safety equipment, prioritizing on-the-ground stability and protection with a low, flat-treaded heel and features like steel toes.

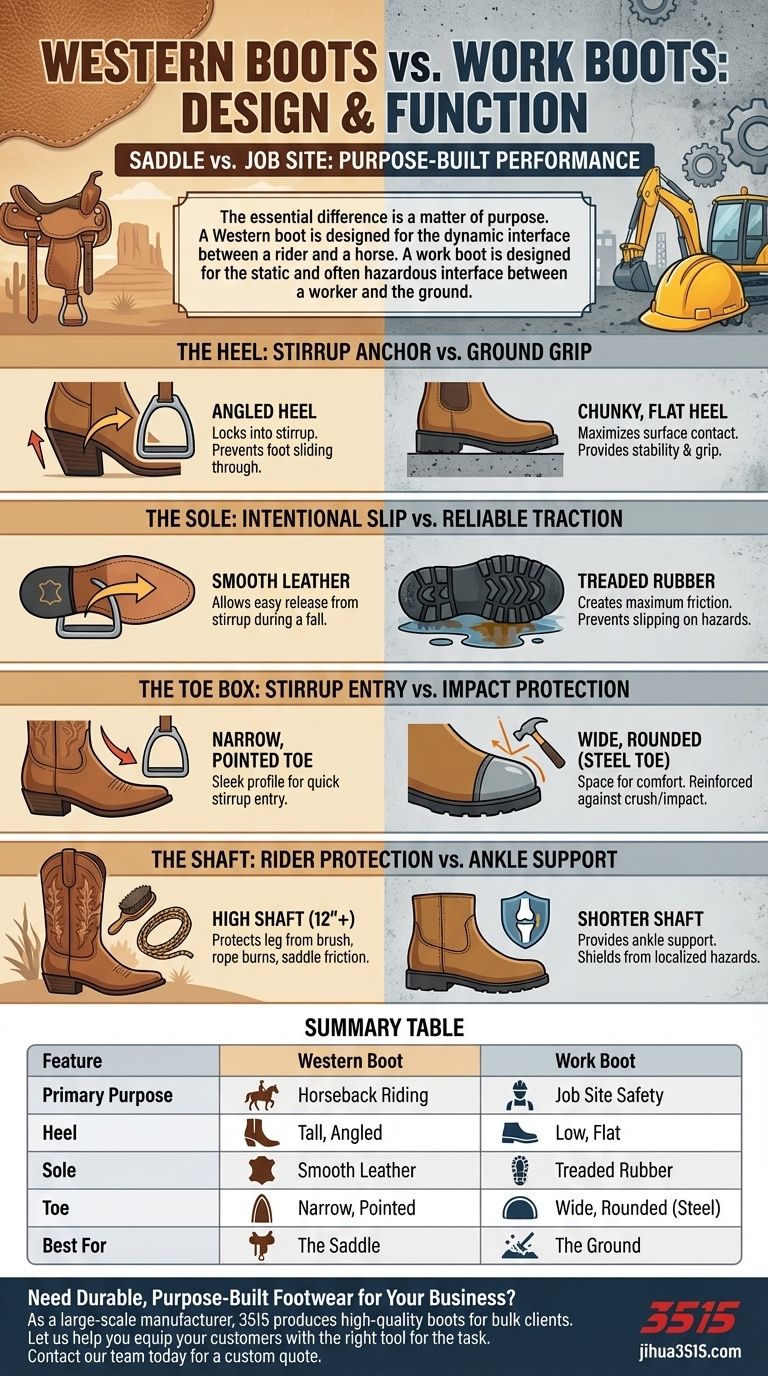

The essential difference is a matter of purpose. A Western boot is designed for the dynamic interface between a rider and a horse. A work boot is designed for the static and often hazardous interface between a worker and the ground.

Deconstructing the Design: Environment Dictates Form

Every element of a boot's construction is a direct response to the demands of its intended use. Understanding these design choices reveals why the two styles are not interchangeable.

The Heel: Stirrup Anchor vs. Ground Grip

A traditional Western boot features a tall, angled heel, often called a "Cuban" or "underslung" heel. Its primary function is to lock into a stirrup, preventing the rider's foot from sliding too far forward and getting stuck.

Work boots, in contrast, have a much lower, chunkier heel with a wide, flat base. This design maximizes surface contact with the ground, providing stability and grip, especially on uneven or slippery surfaces.

The Sole: Intentional Slip vs. Reliable Traction

The sole of a classic Western boot is made of smooth leather. This is a critical safety feature for riding, allowing the boot to easily slide out of the stirrup if the rider falls.

Work boots are equipped with thick rubber outsoles that feature deep, aggressive treads. Their purpose is the exact opposite: to create maximum friction and prevent slipping on industrial surfaces like concrete, mud, or steel.

The Toe Box: Stirrup Entry vs. Impact Protection

Western boots traditionally have a narrow, pointed toe. This sleek profile makes it easier for a rider to quickly guide their foot into the stirrup.

Work boots feature a much wider, more rounded toe box, often reinforced with a steel toe cap. This space and reinforcement are designed purely for protection against crushing or impact hazards common on job sites.

The Shaft: Rider Protection vs. Ankle Support

The iconic high shaft of a Western boot (often 12 inches or more) serves two purposes. It protects the rider's legs from brush, rope burns, and the friction of the saddle. It also serves as a canvas for decorative stitching and style.

Work boots typically have a shorter shaft designed to provide support and protection for the ankle. The focus is on preventing sprains and shielding from localized hazards, not shielding the entire lower leg.

The Rise of the Hybrid: The Western Work Boot

A significant category has emerged that blends the aesthetics of a Western boot with the practical features of a work boot. This hybrid is often called a "Western work boot" or "roper" style.

Blending Form and Function

These boots retain the pull-on style and general shape of a Western boot but replace the riding-specific features with work-oriented ones. They are a direct response to the needs of individuals who work on their feet but prefer the Western look.

Key Features of a Western Work Boot

A Western work boot typically has a lower, straight heel (a "roper" heel), a wider square or round toe box, and a treaded rubber outsole for traction. The design prioritizes walking comfort and on-the-ground stability over stirrup compatibility.

Understanding the Trade-offs and Safety Risks

Using the wrong boot for the environment is not just inefficient; it can be dangerous. Each design's strengths in one context become critical weaknesses in another.

The Danger of Traditional Boots on a Job Site

Wearing a classic Western boot on a construction site is a significant risk. The smooth leather sole offers almost no grip on slick surfaces, and the lack of a protective toe cap leaves the foot vulnerable to serious injury.

The Awkwardness of Work Boots in the Saddle

Conversely, a work boot's chunky rubber sole can be a safety hazard for riding. The deep tread can easily get caught in a stirrup, preventing a rider's foot from coming free during a fall and creating a risk of being dragged.

The Compromise of the Hybrid

While versatile, the Western work boot is a compromise. It is not as specialized for riding as a traditional boot and may not meet the specific, stringent safety certifications (like ASTM ratings) required for certain industrial job sites.

Making the Right Choice for Your Purpose

Your decision should be guided by a clear understanding of your primary activity.

- If your primary focus is horseback riding: Choose a traditional Western boot with a smooth leather sole and an angled heel for optimal stirrup safety and control.

- If your primary focus is safety on an industrial job site: Select a dedicated, certified work boot with a protective toe, a slip-resistant rubber outsole, and any other required safety features.

- If your primary focus is all-day wear for farming, ranching, or outdoor work on foot: A Western work boot is an excellent choice, providing the necessary traction and durability with a familiar style.

Ultimately, your choice of boot is a decision about selecting the right tool for the task at hand.

Summary Table:

| Feature | Western Boot | Work Boot |

|---|---|---|

| Primary Purpose | Horseback Riding | Job Site Safety |

| Heel | Tall, Angled (for stirrups) | Low, Flat (for stability) |

| Sole | Smooth Leather (easy stirrup release) | Treaded Rubber (slip resistance) |

| Toe | Narrow, Pointed | Wide, Rounded (often steel-toed) |

| Best For | The Saddle | The Ground |

Need Durable, Purpose-Built Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality boots for distributors, brand owners, and bulk clients. Whether you need authentic Western boots for equestrian markets or certified safety work boots for industrial applications, our production capabilities ensure superior craftsmanship, durability, and style.

Let us help you equip your customers with the right tool for the task.

Contact our team today to discuss your manufacturing needs and receive a custom quote.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the difference between regular boots and waterproof boots in terms of design? The Critical Feature Explained

- Can motorcycle boots be worn for everyday use? Finding the Perfect Balance for Daily Wear

- What industries are Western work boots suitable for? A Guide for Demanding Professionals

- Why perform macrofoam swab sampling on work boots? Ensure Site Safety & Prevent Hazardous Cross-Contamination

- How many layers of wax are recommended for optimal waterproofing? The Secret to a Durable Seal

- What are the sizing and fit considerations for women's work boots? A Safety & Comfort Guide

- What are the different types of boot toes available? Choose the Right Toe for Your Job

- How do enclosed safety boots provide environmental isolation? Block Dust and Liquids in Hazardous Workplaces