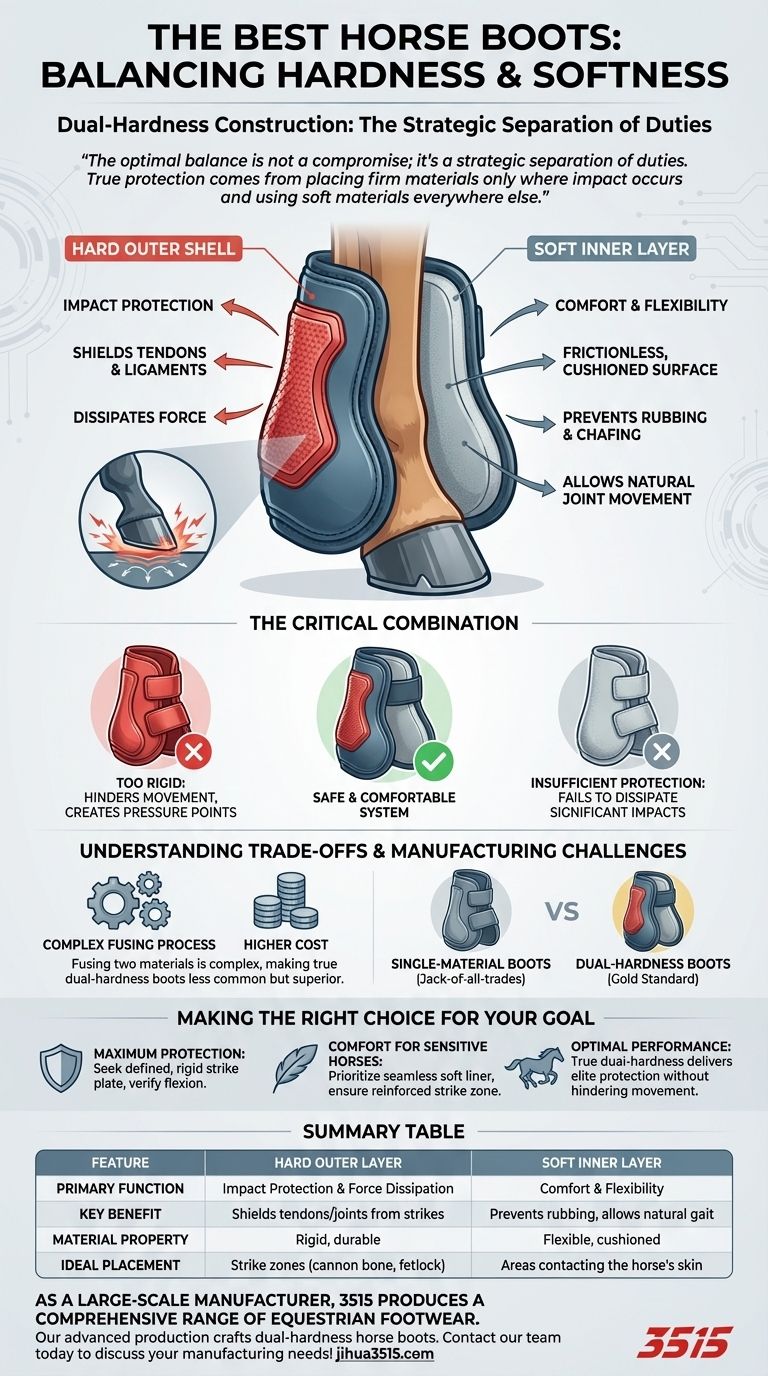

The hallmark of a superior horse boot lies not in finding a single perfect material, but in its intelligent use of two distinct materials. The best designs feature a dual-hardness construction, combining a firm, protective outer layer in key strike zones with a softer, flexible inner layer that contacts the horse's leg. This sophisticated approach provides robust protection without compromising comfort or the horse's natural range of motion.

The optimal balance between hardness and softness is not a compromise; it's a strategic separation of duties. True protection comes from placing firm materials only where impact occurs and using soft materials everywhere else for comfort and flexibility.

The Anatomy of a Dual-Hardness Boot

To understand why this balance is so crucial, you must think of a boot as having two distinct jobs: dissipating force and ensuring comfort. A single material cannot excel at both.

The Protective Outer Shell

The hard outer material serves one primary purpose: impact protection. It is strategically placed over the areas most vulnerable to strikes, such as the back of the cannon bone and the fetlock joint.

This firm layer acts like a shield, distributing the force of a direct impact over a wider area. This prevents the concentrated energy from a hoof or a pole from causing a severe injury to the delicate tendons and ligaments beneath.

The Comfortable Inner Layer

The soft inner material is what directly touches the horse's sensitive skin and contours to the leg. Its role is to provide a frictionless, cushioned surface.

This layer prevents rubbing and chafing, allows the joint to flex without restriction, and helps the boot conform securely to the leg. A boot that is too rigid everywhere will inevitably hinder movement and create painful pressure points.

Why This Combination is Critical

A boot made entirely of hard material would be excessively restrictive and uncomfortable, potentially altering the horse's gait. Conversely, a boot made entirely of soft material would offer insufficient protection against a sharp, forceful strike.

The dual-hardness design solves this dilemma by assigning each task to a specialized material, creating a system that is both safe and comfortable.

Understanding the Trade-offs

While the dual-hardness principle represents the gold standard in boot design, its implementation presents challenges that lead to compromises in many products on the market.

The Manufacturing Challenge

Fusing two materials with different hardness levels into a single, seamless product is a complex and costly manufacturing process.

This difficulty is why true dual-hardness boots are less common and often command a higher price. It is simpler and cheaper to produce a boot from a single mold of uniform material.

The Risk of Single-Material Boots

Many boots are made from a single material that attempts to be a "jack-of-all-trades." This approach is always a compromise.

If the material is hard enough to offer good protection, it's often too stiff for optimal comfort. If it's soft enough for comfort, it likely lacks the rigidity needed to dissipate a significant impact.

Making the Right Choice for Your Goal

When evaluating horse boots, look past the color and marketing and focus on the underlying construction. Your priority will determine which features matter most.

- If your primary focus is maximum protection: Seek out a boot with a clearly defined, rigid strike plate on the exterior, and verify that the rest of the boot allows for proper flexion.

- If your primary focus is comfort for sensitive horses: Prioritize a boot with a seamless, soft inner lining, but do not sacrifice the essential reinforced strike zone on the outer shell.

- If your primary focus is optimal performance: A true dual-hardness boot is the ideal choice, as it delivers elite protection without hindering the horse's natural movement.

By understanding this core design principle, you can more effectively assess a boot's true quality and make an informed decision that supports your horse's safety and well-being.

Summary Table:

| Feature | Hard Outer Layer | Soft Inner Layer |

|---|---|---|

| Primary Function | Impact Protection & Force Dissipation | Comfort & Flexibility |

| Key Benefit | Shields tendons/joints from strikes | Prevents rubbing, allows natural gait |

| Material Property | Rigid, durable | Flexible, cushioned |

| Ideal Placement | Strike zones (cannon bone, fetlock) | Areas contacting the horse's skin |

As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities allow us to expertly craft dual-hardness horse boots that deliver the perfect balance of protection and comfort. Let us help you develop high-performance boots that meet your exact specifications. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the largest venomous snake in South America? The Bushmaster's Formidable Threat

- What is the function of infrared reflective anatomical markers in footwear modeling? Unlock Biomechanical Precision

- Why is metal fabric selected as the substrate material for smart electronic skins? Superior Conductive Skelton Benefits

- Why is research into the durability and stretchability of fabrics essential for smart gear? Optimize Safety Designs

- What are the advantages of organic cotton, hemp, or recycled fabrics in footwear? Boost Sustainability & Efficiency

- What are the variations in cowboy boot height and design? Find the Perfect Fit for Your Needs

- Why is the use of high-performance footwear necessary during the biomechanical adjustment and dynamic capture process?

- What dual roles does EVA foam perform in a capacitive pressure sensor? Unlocking Precision in Smart Footwear Sensors