To be clear, slip-resistant shoes comply with OSHA regulations by acting as a critical form of Personal Protective Equipment (PPE) that addresses a known workplace hazard. OSHA mandates that employers provide a work environment free from recognized slip, trip, and fall dangers. Certified slip-resistant footwear is a primary and accepted method for employers to meet this requirement in environments with slippery walking surfaces.

The core principle is this: OSHA doesn't certify specific shoe brands, but it does mandate the prevention of slip hazards. Using properly rated slip-resistant shoes is how an employer demonstrates compliance with that mandate, effectively mitigating risk and fulfilling their legal responsibility for worker safety.

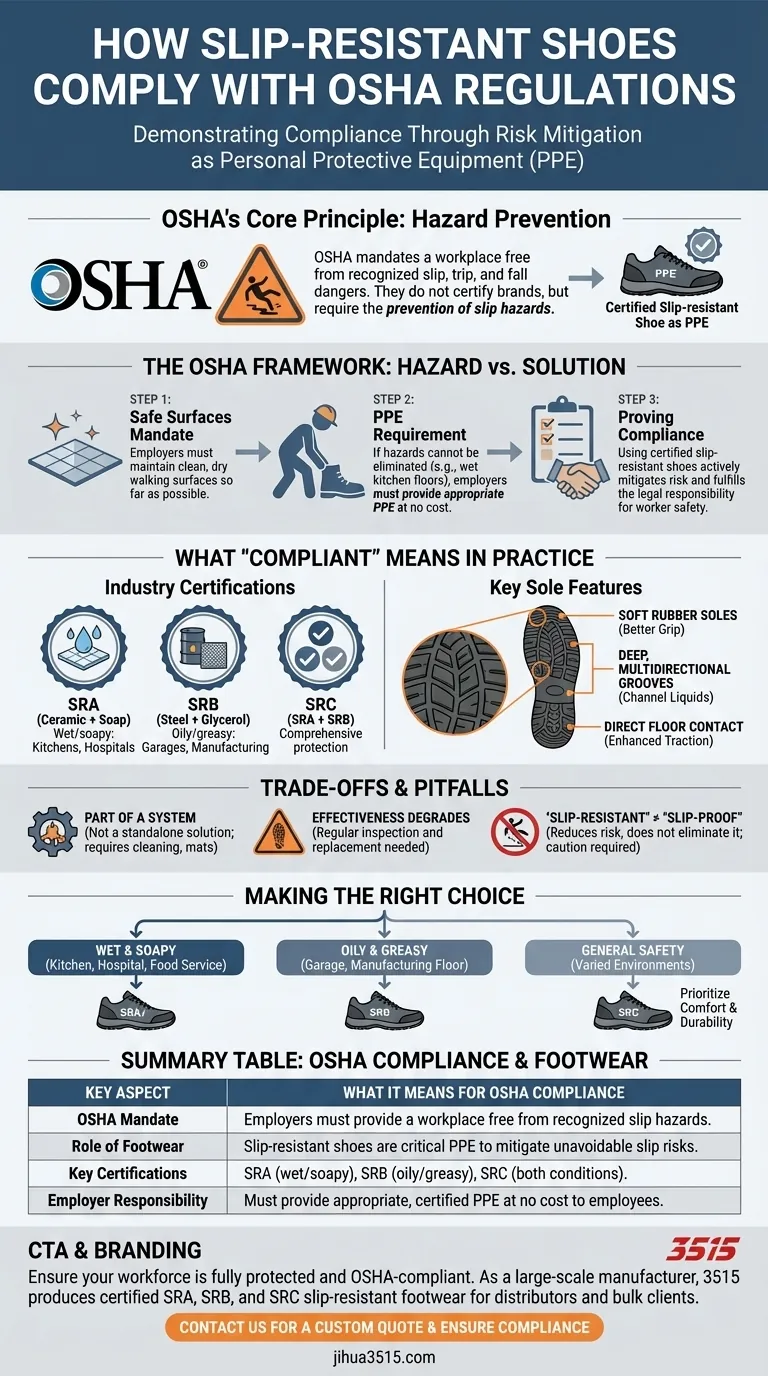

The OSHA Framework: Hazard vs. Solution

OSHA's approach to workplace safety is built on identifying and mitigating hazards. Slip-resistant footwear is not a regulation in itself, but rather a solution to a regulated problem.

OSHA's Mandate for Safe Surfaces

The foundation of this requirement is OSHA's standard for walking-working surfaces. The regulation states that floors in a workplace must be maintained in a clean and, so far as possible, a dry condition.

The Role of Personal Protective Equipment (PPE)

When a hazard cannot be eliminated entirely—such as in a commercial kitchen where floors are frequently wet—OSHA requires employers to provide workers with appropriate PPE at no cost. Slip-resistant shoes fall directly into this category.

Proving Compliance Through Use

By providing employees with footwear designed to prevent slips on the specific surfaces they encounter, an employer actively demonstrates they are taking necessary steps to protect their team and comply with the spirit and letter of the law.

What "Compliant" Means in Practice

True compliance goes beyond simply buying any shoe labeled "slip-resistant." It involves selecting footwear with verifiable performance features that match the specific risks of your environment.

Look for Industry Certifications

The most reliable indicators of performance are industry-standard certifications. These ratings show a shoe has passed rigorous, standardized tests.

Key certifications include SRA, tested on ceramic tile with a soap solution, and SRB, tested on smooth steel with glycerol. A shoe rated SRC has passed both SRA and SRB test conditions, offering the most comprehensive protection.

Key Features of an Effective Sole

The design of the outsole is what provides traction. Look for soft rubber soles, which offer a better grip than hard plastic materials.

The most effective designs feature deep, multidirectional grooves or tread patterns. This helps channel liquids out from under the shoe, allowing the sole to make direct contact with the floor.

Understanding the Test Environment

The certification that matters most depends on your work environment. SRA is ideal for soapy or wet conditions, like kitchens and hospitals. SRB is critical for greasy or oily surfaces, common in garages and manufacturing.

Understanding the Trade-offs and Pitfalls

While essential, slip-resistant shoes are not a complete solution on their own and come with their own set of considerations.

They Are Part of a System

Slip-resistant shoes are your last line of defense. A comprehensive safety program must also include regular cleaning of spills, proper drainage, and the use of high-traction floor mats.

Effectiveness Degrades Over Time

The tread on any shoe wears down with use. As the deep grooves become shallow, the shoe's ability to resist slips diminishes significantly. Regular inspection and replacement are critical for maintaining safety.

"Slip-Resistant" Is Not "Slip-Proof"

No shoe can guarantee a complete prevention of slips in all conditions. They drastically reduce risk, but they do not eliminate it. Caution and awareness remain essential worker responsibilities.

Making the Right Choice for Your Goal

To ensure genuine compliance and safety, select footwear based on the specific hazards your team faces.

- If your primary focus is a kitchen, hospital, or food service area: Prioritize shoes with an SRA or, ideally, an SRC rating to handle wet and soapy conditions.

- If your primary focus is an industrial garage or manufacturing floor: An SRB or SRC rating is non-negotiable to protect against oil and glycerol-based slips.

- If your primary focus is general safety across varied environments: Choose an SRC-rated shoe and prioritize comfort and durability to ensure employees wear them consistently and correctly.

Ultimately, choosing the right footwear is a proactive investment in a safe and compliant workplace.

Summary Table:

| Key Aspect | What It Means for OSHA Compliance |

|---|---|

| OSHA Mandate | Employers must provide a workplace free from recognized slip hazards. |

| Role of Footwear | Slip-resistant shoes are critical PPE to mitigate unavoidable slip risks. |

| Key Certifications | SRA (wet/soapy surfaces), SRB (oily/greasy surfaces), SRC (both conditions). |

| Employer Responsibility | Must provide appropriate, certified PPE at no cost to employees. |

Ensure your workforce is fully protected and OSHA-compliant.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet SRA, SRB, and SRC standards, helping you mitigate risk and fulfill your legal safety obligations.

Contact us today to discuss your specific needs and receive a custom quote for reliable, compliant footwear solutions.

Get a Custom Quote & Ensure Compliance

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- What is the purpose of steel-toe moc toe boots? Achieve All-Day Safety and Comfort

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide