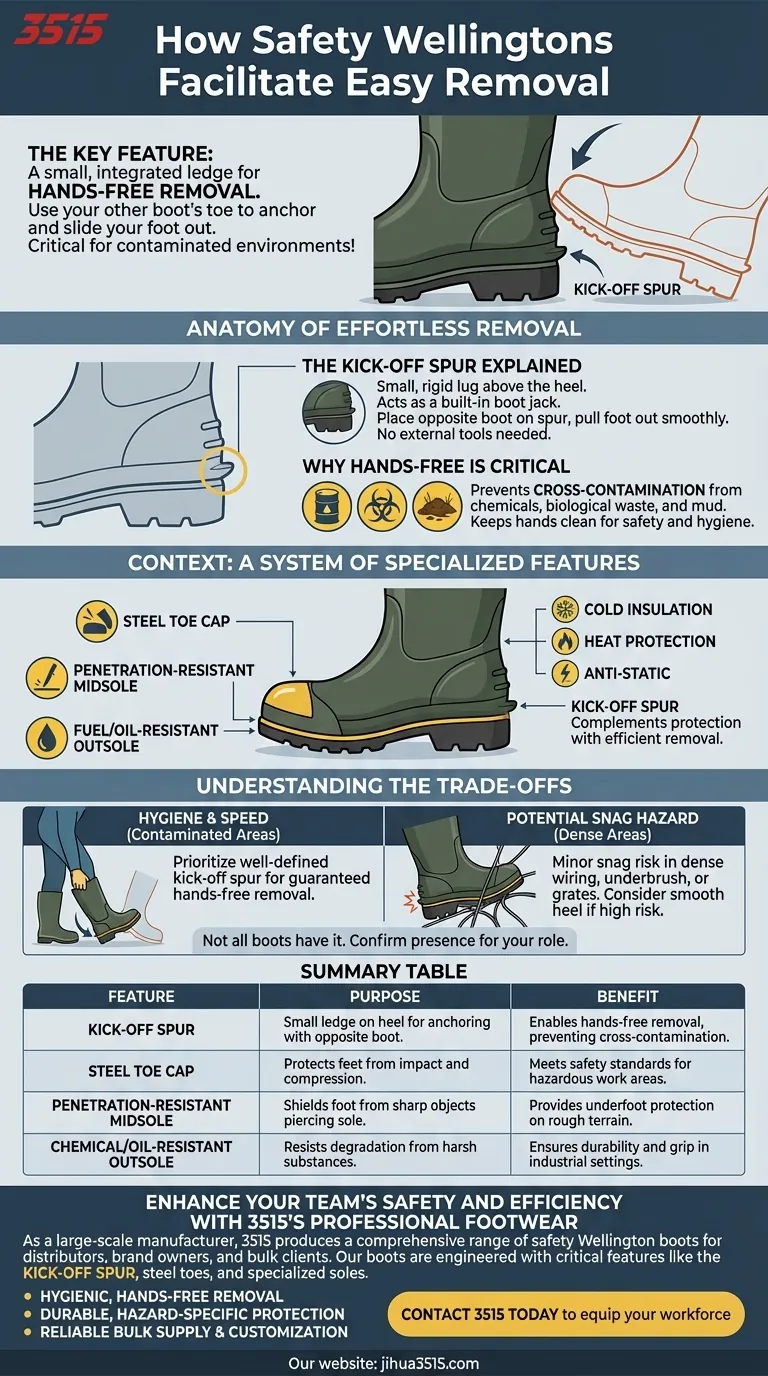

The key feature that facilitates the easy, hands-free removal of safety Wellington boots is a small, integrated ledge on the back of the heel known as a kick-off spur. This simple design element allows you to use the toe of your other boot to secure the heel and slide your foot out without bending down or using your hands, a critical function in contaminated or dirty environments.

The kick-off spur is not merely a convenience; it is a crucial design consideration for professionals who require rapid, hygienic, and safe footwear removal in demanding work conditions.

The Anatomy of Effortless Removal

Understanding how a safety Wellington is designed for easy removal goes beyond its basic shape. It centers on a specific feature purpose-built for professional workflows.

The Kick-Off Spur Explained

The kick-off spur is a small, rigid lug or protrusion molded into the back of the boot, just above the heel.

To use it, you simply place the arch or toe of your opposite boot onto this spur. This anchors the boot you are removing, allowing you to pull your foot out smoothly and cleanly.

This mechanism acts as a built-in boot jack, eliminating the need for external tools or contorting your body to remove a snug-fitting boot.

Why Hands-Free Removal is Critical

In many professional settings, touching your boots is not an option. Environments involving chemicals, biological waste, or excessive mud require a hands-free solution to prevent cross-contamination.

Keeping your hands clean is paramount for safety and hygiene. The kick-off spur ensures you can de-boot without compromising hand cleanliness before breaks or at the end of a shift.

Context: A System of Specialized Features

The kick-off spur is one component of a highly specialized piece of personal protective equipment (PPE). Its value is best understood in the context of the boot's other protective features.

More Than Just Waterproofing

Modern safety Wellingtons are engineered for specific hazards. They often include steel toe caps, penetration-resistant midsoles, and fuel and oil-resistant outsoles.

Depending on the intended environment, they may also feature cold insulation for low-temperature work, heat protection, or anti-static properties to prevent electrostatic discharge. The kick-off spur complements these features by ensuring the boot can be removed safely and efficiently.

Understanding the Trade-offs

While highly effective, the kick-off spur is a design choice with specific implications that may not be suitable for every single application.

A Potential Snag Hazard

The spur is a protrusion. In environments with dense wiring, underbrush, or floor grates, it can present a minor snagging risk. This is a rare consideration but one to be aware of.

Not a Universal Feature

Not all safety Wellingtons include a kick-off spur. It is a specific feature you must look for when purchasing. If hands-free removal is a priority for your role, you must confirm its presence.

Making the Right Choice for Your Workflow

Selecting the appropriate boot depends entirely on the demands of your work environment.

- If your primary focus is hygiene and speed in contaminated areas: Prioritize a safety Wellington with a well-defined kick-off spur for guaranteed hands-free removal.

- If your primary focus is all-around protection in moderately clean environments: A kick-off spur is still a significant convenience feature that improves daily workflow, but it may not be a critical requirement.

- If your primary focus is working in environments with high snagging potential: You might consider a boot with a smooth heel profile to minimize risk, accepting the need to use your hands for removal.

Ultimately, choosing the right footwear is about enhancing both your safety and your operational efficiency.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Kick-Off Spur | A small ledge on the heel for anchoring with the opposite boot. | Enables hands-free removal, preventing cross-contamination. |

| Steel Toe Cap | Protects feet from impact and compression. | Meets safety standards for hazardous work areas. |

| Penetration-Resistant Midsole | Shields the foot from sharp objects piercing the sole. | Provides underfoot protection on rough terrain. |

| Chemical/Oil-Resistant Outsole | Resists degradation from harsh substances. | Ensures durability and grip in industrial settings. |

Enhance Your Team's Safety and Efficiency with 3515's Professional Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of safety Wellington boots for distributors, brand owners, and bulk clients. Our boots are engineered with critical features like the kick-off spur, steel toes, and specialized soles to meet the demands of your toughest work environments.

We ensure:

- Hygienic, hands-free removal to keep workers safe from contaminants.

- Durable, hazard-specific protection tailored to your industry's needs.

- Reliable bulk supply and customization options for your business.

Contact 3515 today to equip your workforce with safety footwear that combines protection, comfort, and smart design for optimal productivity.

Visual Guide

Related Products

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What is ASTM International and what does it do? A Guide to Global Standards

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- Why is maintenance important for work boots? Protect Your Investment and Safety