The fundamental difference between S4 and S1 safety footwear is water resistance. While both ratings provide an identical baseline of protection, S1 footwear is designed exclusively for dry environments. S4 boots, however, are constructed from fully waterproof polymer materials, making them the required choice for work in wet or damp conditions.

The decision between S1 and S4 is not about which is "better," but which is appropriate for the environment. S1 offers breathable protection for dry tasks, while S4 provides essential waterproof protection for wet conditions.

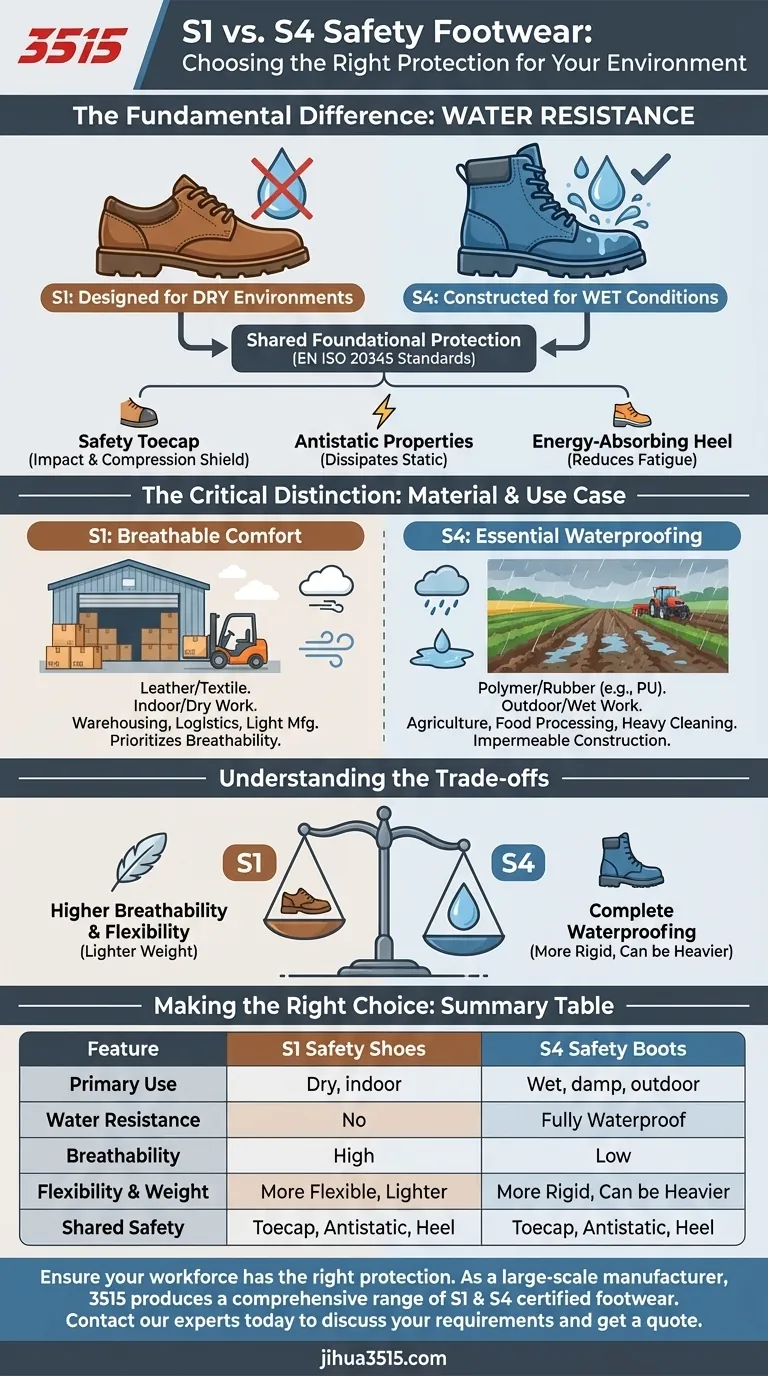

Foundational Protection: The Shared Features of S1 and S4

Both S1 and S4 ratings are built upon the same core safety standards established by EN ISO 20345. This means any footwear labeled S1 or S4 will include these three non-negotiable features.

Safety Toecap

This is the most fundamental feature of safety footwear. A protective toecap, typically made of steel or composite materials, shields the wearer's toes from heavy impact and compression forces.

Antistatic Properties

Both ratings require an antistatic outsole. This feature safely dissipates static electricity into the ground, reducing the risk of electrostatic discharge which can damage sensitive electronic components or cause ignition in certain environments.

Energy-Absorbing Heel

This feature is designed for wearer comfort and health. The heel region is engineered to absorb shock and impact during walking, reducing fatigue and long-term strain on the joints and back.

The Critical Distinction: Material and Environment

The divergence between S1 and S4 lies entirely in their construction materials and, therefore, their intended use case.

S1: Engineered for Dry Conditions

S1 safety shoes are typically made from materials like leather or other breathable textiles. They are designed for indoor work or outdoor work in consistently dry weather.

Their construction prioritizes comfort and breathability over water resistance. They are ideal for roles in logistics, warehousing, or light manufacturing where the primary hazards are impact and static electricity, not liquids.

S4: Built for Wet Environments

S4 safety boots are fundamentally different in their build. They are molded from a polymer or rubber material, such as Polyurethane (PU), making the entire boot waterproof.

This is not a spray-on treatment; the material itself is impermeable. This makes S4 boots essential for work in agriculture, food processing, heavy cleaning, or any job that involves standing water, mud, or persistent rain.

Understanding the Trade-offs

Choosing between these two standards involves a direct trade-off between water protection and all-day comfort in dry conditions.

Breathability vs. Waterproofness

The primary trade-off is breathability. S1 shoes, with their leather or fabric uppers, allow moisture and heat to escape, keeping feet more comfortable during long, dry shifts.

S4 boots, being completely waterproof, are not breathable. In hot and dry environments, this can lead to discomfort and excessive sweating.

Flexibility and Weight

S1 safety footwear often resembles a standard trainer or shoe, offering greater flexibility and a lighter weight.

In contrast, S4 boots are typically more rigid and can be heavier due to their solid polymer construction, which can feel more cumbersome for tasks requiring high agility.

Making the Right Choice for Your Task

Your work environment is the only factor that should guide your decision.

- If your primary focus is working indoors in a dry environment (e.g., warehousing, assembly lines, logistics): S1 footwear provides all the necessary protection while maximizing breathability and comfort.

- If your primary focus involves any exposure to water, mud, or other liquids (e.g., agriculture, construction in the rain, industrial cleaning): S4 footwear is the mandatory choice to keep your feet dry, safe, and healthy.

Ultimately, selecting the correct safety rating is a direct assessment of the hazards and conditions you face daily.

Summary Table:

| Feature | S1 Safety Shoes | S4 Safety Boots |

|---|---|---|

| Primary Use | Dry, indoor environments | Wet, damp, or outdoor environments |

| Water Resistance | No | Fully waterproof (polymer construction) |

| Breathability | High (leather/textile uppers) | Low |

| Flexibility & Weight | More flexible, lighter | More rigid, can be heavier |

| Shared Safety Features | Safety toecap, antistatic sole, energy-absorbing heel | Safety toecap, antistatic sole, energy-absorbing heel |

Ensure your workforce has the right safety footwear for their specific environment. As a large-scale manufacturer, 3515 produces a comprehensive range of S1 and S4 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant, and comfortable footwear tailored to your needs. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management