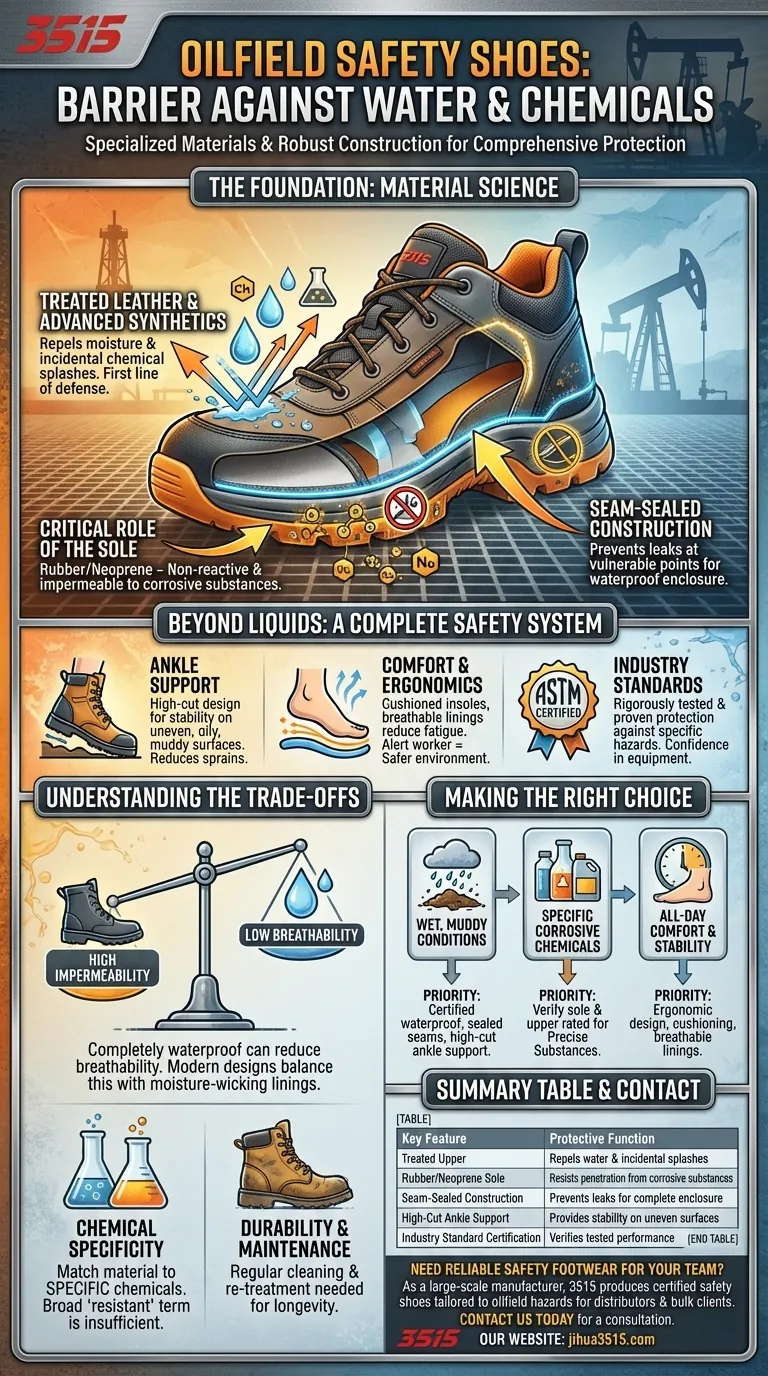

Oilfield safety shoes create a barrier against water and chemicals through the deliberate selection of specialized materials and robust construction. The shoe's upper is typically made from treated, water-repellent leather or advanced synthetic fabrics, while the sole is crafted from highly resistant compounds like rubber or neoprene to prevent penetration by corrosive substances. This dual-layer material strategy ensures comprehensive protection from environmental and chemical hazards.

The effectiveness of an oilfield safety shoe is not due to a single feature, but a complete protective system. It combines waterproof uppers with chemically inert soles to create a reliable shield against the specific liquid hazards found in demanding work environments.

The Foundation of Protection: Material Science

The core of a safety shoe's defense lies in the materials chosen for its construction. Each component is engineered to resist specific types of threats common in oilfield operations.

Treated Leather and Advanced Synthetics

The main body, or "upper," of the shoe serves as the first line of defense. Manufacturers use high-grade leather treated with waterproofing agents or specialized synthetic fabrics that inherently repel liquids. This prevents moisture and incidental chemical splashes from soaking through to the foot.

The Critical Role of the Sole

The outsole is the part of the shoe in direct and prolonged contact with the ground, where spills and puddles are common. Materials like rubber and neoprene are used because they are largely non-reactive and impermeable, preventing chemical burns and absorption of harmful substances.

Seam-Sealed Construction

Beyond the materials themselves, high-quality safety shoes feature sealed seams and strong bonding between the upper and the sole. This construction detail is critical for preventing leaks at the shoe's most vulnerable points, ensuring a truly waterproof and chemically resistant enclosure.

Beyond Liquids: A Complete Safety System

While resistance to water and chemicals is crucial, oilfield safety shoes are designed to address a wider range of worksite hazards. True safety comes from a combination of protective features.

Ankle Support for Unstable Ground

Many oilfield boots feature a high-cut design that extends above the ankle. This provides essential stability on uneven, muddy, or grated surfaces, significantly reducing the risk of sprains and falls.

Comfort as a Non-Negotiable Safety Feature

Long shifts demand footwear that remains comfortable. Features like cushioned insoles, breathable linings, and ergonomic designs reduce foot fatigue. A comfortable worker is a more focused and alert worker, which directly translates to a safer work environment.

The Assurance of Industry Standards

Reputable safety footwear is certified to meet strict industry standards (such as those from ASTM International). This compliance verifies that the shoe has been rigorously tested and proven to provide the stated level of protection against specific hazards, giving you confidence in your equipment.

Understanding the Trade-offs

Choosing the right footwear requires understanding the inherent compromises in design and materials. No single boot is perfect for every possible situation.

Breathability vs. Impermeability

A completely waterproof and chemically sealed boot is, by nature, less breathable. This can lead to heat and sweat buildup, causing discomfort. Modern designs mitigate this with moisture-wicking linings, but a balance must always be struck.

Chemical Specificity

"Chemical-resistant" is a broad term. A material that resists hydrocarbons may not be effective against strong acids or bases. It is crucial to match the boot’s material specifications to the specific chemicals present in your work environment.

Durability and Maintenance

The protective treatments on leather and synthetic uppers can degrade over time with wear, tear, and exposure. Regular cleaning and re-treatment are necessary to maintain the shoe's original level of resistance and extend its service life.

Making the Right Choice for Your Environment

Your specific job function and environment should dictate your choice of footwear.

- If your primary focus is working in wet, muddy conditions: Prioritize shoes with certified waterproof construction, sealed seams, and a high-cut design for ankle support.

- If your primary focus is handling specific corrosive chemicals: Verify the boot's sole and upper materials are rated to resist the precise substances you work with.

- If your primary focus is all-day comfort and stability: Look for ergonomic designs with superior cushioning and breathable linings to minimize fatigue on long shifts.

Ultimately, selecting the right safety shoe is about matching its specific protective technologies to the precise hazards you face daily.

Summary Table:

| Key Feature | Protective Function |

|---|---|

| Treated Leather/Synthetic Upper | Repels water and incidental chemical splashes. |

| Rubber/Neoprene Sole | Resists penetration from corrosive substances on the ground. |

| Seam-Sealed Construction | Prevents leaks at vulnerable joints for complete enclosure. |

| High-Cut Ankle Support | Provides stability on uneven, oily, or muddy surfaces. |

| Industry Standard Certification | Verifies tested performance against specific hazards (e.g., ASTM). |

Need reliable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, chemically resistant footwear tailored to the specific hazards of the oilfield environment.

Contact us today for a consultation and discover how we can equip your workforce with superior protection.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries