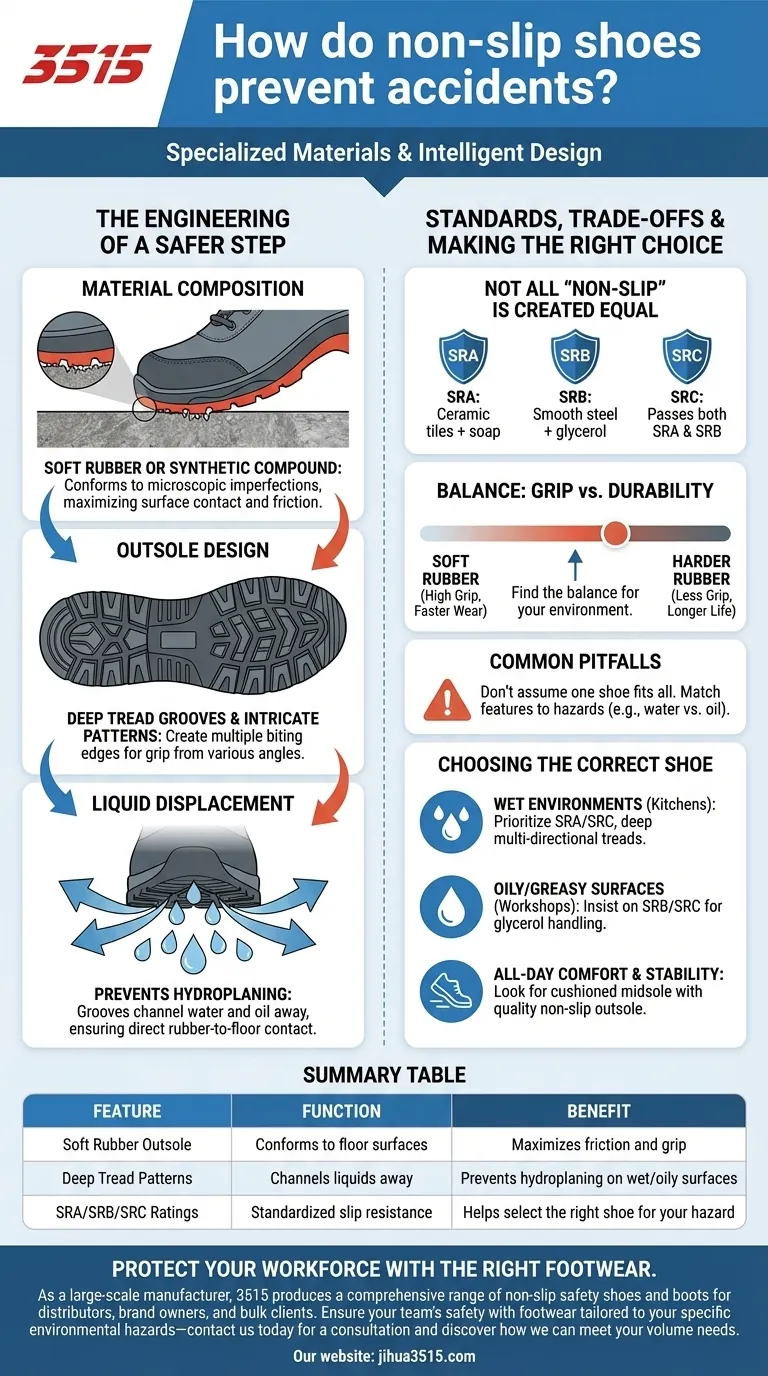

At their core, non-slip shoes prevent accidents by using a combination of specialized materials and intelligent outsole design. The soft rubber soles create high friction, while deep, intricate tread patterns work to channel liquids like water and oil away from the point of contact, ensuring the sole maintains a firm grip on the walking surface.

The true function of a non-slip shoe is not just to grip, but to actively manage the slippery contaminants underfoot. Its effectiveness is an engineering outcome, combining high-friction materials with tread patterns designed to displace liquids and maintain direct contact with the ground.

The Engineering of a Safer Step

To understand how these shoes work, you have to look at the two critical components of their design: the material they are made from and the physical pattern of the sole itself.

The Role of Material Composition

The choice of material for the outsole is the foundation of slip resistance. Most high-performance non-slip shoes use a soft rubber or synthetic rubber compound.

Unlike harder materials, this softer compound can conform slightly to microscopic imperfections in a floor's surface. This dramatically increases the surface area of contact, which in turn maximizes friction.

The Importance of Outsole Design

The pattern on the bottom of the shoe is just as important as the material. These are not random designs; they are engineered for a specific purpose.

The outsole features deep tread grooves and intricate patterns. This rugged topography creates multiple edges that can bite into the walking surface, providing grip from various angles.

How Treads Channel Away Liquids

The most critical function of the tread pattern is to prevent hydroplaning. When you step on a wet or oily surface, a thin layer of liquid can get trapped between your shoe and the floor.

The grooves in the outsole act as channels, quickly squeezing the liquid out and away from the center of the sole. This allows the rubber to make direct, solid contact with the floor, which is essential for maintaining traction.

Understanding the Standards and Trade-offs

Simply choosing a shoe labeled "non-slip" is not enough. The term can be subjective, which is why official standards and an understanding of inherent limitations are crucial for making an informed safety decision.

Not All "Non-Slip" Is Created Equal

To standardize performance, safety shoes are often tested and rated against specific conditions. These ratings tell you how a shoe performs in a controlled environment.

- SRA: Tested on ceramic tiles wetted with a soap solution.

- SRB: Tested on smooth steel with glycerol (an oily substance).

- SRC: The highest rating, indicating the shoe has passed both SRA and SRB tests.

The Balance Between Grip and Durability

There is often a trade-off between the softness of the rubber and the shoe's lifespan. An extremely soft rubber compound will offer superior grip but may wear down faster, especially on abrasive surfaces.

Manufacturers are constantly innovating to find a balance, but it's a key factor to consider based on your specific work environment and how often you can replace footwear.

Common Pitfalls to Avoid

The biggest mistake is assuming one shoe fits all slippery conditions. A tread pattern excellent for water may not be optimal for thick, greasy oils. Always match the shoe's features and safety rating to the primary hazards you face.

Making the Right Choice for Your Environment

Choosing the correct non-slip shoe means matching its specific features to your daily hazards.

- If your primary focus is working in wet environments like kitchens: Prioritize a shoe with an SRA or SRC rating and deep, multi-directional treads to effectively channel water.

- If your primary focus is on oily or greasy surfaces in workshops: Insist on a shoe with an SRB or SRC rating, as its material and design are proven to handle glycerol-like substances.

- If your primary focus is all-day comfort and general stability: Look for a shoe that combines a quality non-slip outsole with a well-cushioned, shock-absorbing midsole to reduce fatigue.

Understanding these principles allows you to move beyond marketing claims and select footwear that provides genuine, engineered safety.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Soft Rubber Outsole | Conforms to floor surfaces | Maximizes friction and grip |

| Deep Tread Patterns | Channels liquids away | Prevents hydroplaning on wet/oily surfaces |

| SRA/SRB/SRC Ratings | Standardized slip resistance | Helps select the right shoe for your hazard |

Protect your workforce with the right footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear engineered for superior slip resistance, durability, and comfort. Ensure your team's safety with footwear tailored to your specific environmental hazards—contact us today for a consultation and discover how we can meet your volume needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today