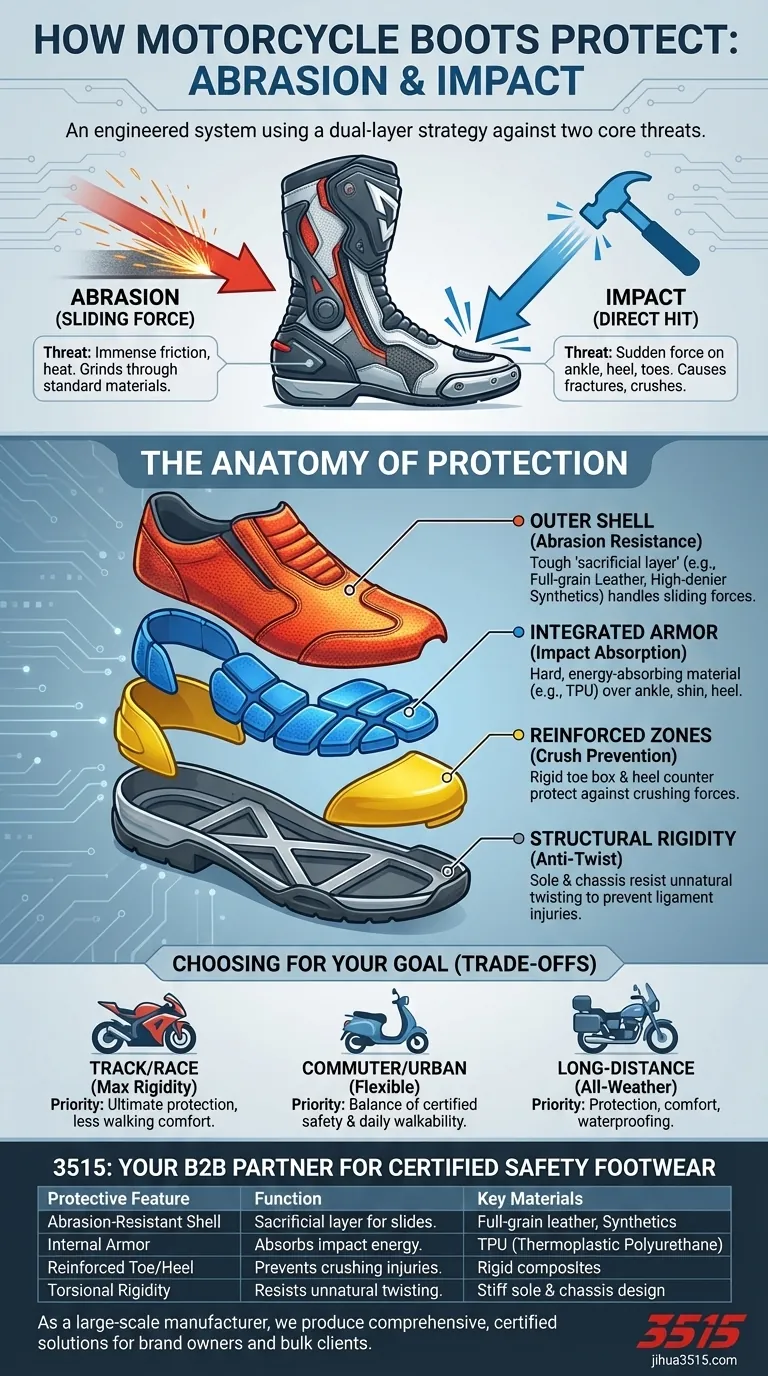

Motorcycle boots protect riders by using a dual-layer strategy: a tough, abrasion-resistant outer shell made of materials like leather or durable synthetics handles sliding forces, while internal armor and reinforced structures absorb and distribute the energy from direct impacts. This combination is specifically engineered to counter the distinct forces present in a motorcycle accident.

A common mistake is viewing a boot as a single piece of protection. In reality, a proper motorcycle boot is an engineered system designed to defeat two separate enemies: the intense, grinding force of abrasion and the sudden, sharp force of impact.

The Two Core Threats to a Rider's Feet

To understand how a boot works, you must first understand the physics of a crash. Riders face two primary types of injury-causing forces, and a boot must be equipped to handle both.

Understanding Abrasion

In a slide, your boot becomes the sacrificial layer between your foot and the asphalt. The friction is immense, generating enough heat and force to grind through standard materials like canvas or thin leather in less than a second.

Motorcycle boots counter this with a robust outer chassis. Materials like full-grain leather or high-denier synthetic textiles are chosen for their exceptional resistance to being worn away, protecting your skin from severe road rash.

Understanding Impact

Impact occurs when your foot hits the pavement, another vehicle, or even your own motorcycle. These forces are concentrated in small areas and can easily lead to fractures, sprains, or crushing injuries.

The most vulnerable areas are the ankle, heel, and toes. This is where a boot's internal protection system is most critical.

The Anatomy of a Protective Motorcycle Boot

A certified motorcycle boot is not simply a sturdy piece of footwear. It is a multi-component safety device where each part has a specific protective function.

The Outer Shell: Your First Line of Defense

The main body of the boot is built from highly abrasion-resistant materials. This is what saves your skin during a slide. While thick leather is the traditional choice, modern synthetics and specially treated textiles also offer excellent protection, often with a weight and ventilation advantage.

Integrated Armor: Absorbing the Blow

Beneath the outer shell, you will find armor. This is typically made from a hard, energy-absorbing material like Thermoplastic Polyurethane (TPU) or a composite blend.

This armor is strategically placed over the most vulnerable bones, such as the ankle discs (malleolus), shin, and heel, to absorb and spread impact forces, preventing them from being transferred directly to your body.

Reinforced Zones: Preventing Crushing

The toe box and heel counter are heavily reinforced. Unlike a simple steel toe in a work boot, which is designed for falling objects, a motorcycle boot's reinforcement protects against both impact and crushing forces that can occur if your foot is trapped under the bike.

Structural Rigidity: Preventing Unnatural Bends

A key feature that separates motorcycle boots from casual footwear is torsional rigidity. The sole and chassis are engineered to resist twisting.

This prevents your ankle from bending in unnatural directions during a tumble, dramatically reducing the risk of complex ligament tears and fractures.

Understanding the Trade-offs

Choosing the right boot involves balancing absolute protection with practical usability. There is no single "best" boot, only the best boot for a specific purpose.

The Rigidity Dilemma

The most protective boots, such as those designed for racing, are extremely rigid. While this offers maximum protection against twisting, it also makes them very difficult to walk in. A boot for a daily commuter needs to offer more flexibility.

Material and Weatherproofing

Leather offers a classic feel and excellent abrasion resistance but can be heavy and hot. Advanced synthetic textiles may provide comparable protection with better ventilation and integrated waterproofing, which is a major factor for long-distance or all-weather riders.

The Critical Role of Fit

A boot's protective features are rendered useless if it comes off in a crash. A secure closure system—whether laces, buckles, or zippers—is non-negotiable. The boot must fit snugly without cutting off circulation to ensure it stays in place when you need it most.

Making the Right Choice for Your Goal

Your choice should be dictated by your primary riding style and the level of risk you need to mitigate.

- If your primary focus is track riding or aggressive canyon carving: Prioritize boots with maximum torsional rigidity and extensive external TPU armor on the heel, shin, and ankle.

- If your primary focus is daily commuting or urban riding: Look for a shorter, more flexible boot that still offers certified ankle protection, a reinforced toe box, and a strong, abrasion-resistant chassis.

- If your primary focus is long-distance touring: Emphasize a balance of certified protection, all-day comfort, and robust weatherproofing to handle changing conditions.

Ultimately, selecting certified motorcycle footwear is a direct investment in your safety and your ability to ride with confidence.

Summary Table:

| Protective Feature | Function | Key Materials |

|---|---|---|

| Abrasion-Resistant Outer Shell | Sacrificial layer to protect skin during a slide. | Full-grain leather, high-denier synthetics. |

| Internal Armor | Absorbs and distributes impact energy. | TPU (Thermoplastic Polyurethane). |

| Reinforced Toe/Heel | Prevents crushing injuries. | Rigid composites, reinforced structures. |

| Torsional Rigidity | Resists unnatural ankle twisting. | Stiff sole and chassis design. |

Ready to equip your customers with superior protection?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified motorcycle boots designed for maximum abrasion and impact resistance. We provide high-quality, durable footwear solutions for distributors, brand owners, and bulk clients.

Our production capabilities encompass all types of protective boots, from rigid race models to flexible commuter styles, ensuring you get the right product for your target market.

Contact us today to discuss your specific needs and benefit from our expertise in safety footwear manufacturing.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors