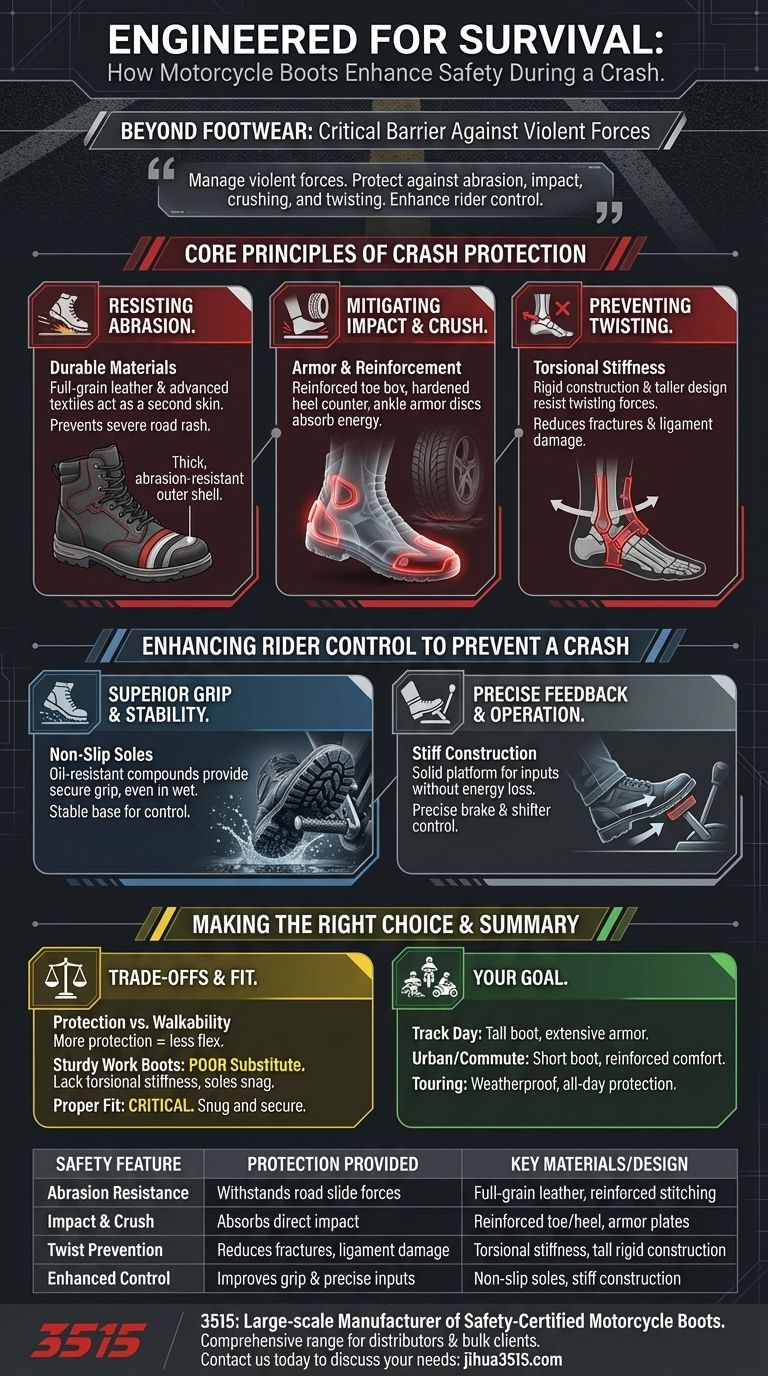

Beyond simple footwear, proper motorcycle boots are a highly engineered piece of safety equipment designed to manage the violent forces of a crash. In the event of an accident, they serve as a critical barrier for your feet and ankles, specifically engineered to protect against abrasion, impact, crushing, and twisting forces that can cause severe injury.

The primary function of motorcycle boots is to absorb and deflect forces during a crash, protecting against abrasion, impact, and twisting injuries. However, their rigid construction and specialized soles also enhance rider control, which can be critical in preventing an accident from ever happening.

The Core Principles of Crash Protection

A motorcycle crash subjects the rider's body to extreme forces. Boots are designed with specific features to counter the most common types of foot and ankle injuries.

Resisting Abrasive Forces

During a slide, asphalt acts like a high-speed belt sander. Motorcycle boots are constructed from thick, durable materials like full-grain leather or advanced textiles that act as a second skin, preventing severe road rash.

Unlike sneakers or casual shoes, which can disintegrate in seconds, the reinforced stitching and robust materials of a riding boot are meant to withstand prolonged contact with the pavement.

Mitigating Impact and Crush Injuries

Your feet are vulnerable to direct impact from the road or being crushed under the weight of the motorcycle.

Proper boots incorporate armor and reinforcement in critical areas. This often includes a reinforced toe box, a hardened heel counter, and dedicated armor discs or plates over the ankle bones to absorb and distribute impact energy.

Preventing Twisting and Hyper-Extension

The ankle is a complex joint that is not designed to bend sideways. Many motorcycle injuries involve severe twisting, leading to fractures and ligament damage.

High-quality boots provide torsional stiffness, meaning they resist twisting forces. Taller boots, in particular, create a rigid structure around the ankle, significantly reducing the risk of hyper-extension and rotational injuries that can be permanently debilitating.

Enhancing Rider Control to Prevent a Crash

The best safety feature is the one that helps you avoid the accident entirely. The construction of a motorcycle boot plays a vital role in how you interact with your bike.

Superior Grip and Stability

The soles of motorcycle boots are made from non-slip, oil-resistant compounds designed to provide a secure grip on your footpegs, even in wet conditions. This ensures your feet stay planted, giving you a stable base for controlling the motorcycle.

Precise Feedback and Operation

The stiff construction of a boot provides a solid platform for operating the rear brake and gear shifter. This rigidity translates your inputs directly to the controls without the energy loss or vague feeling you get from soft-soled shoes, leading to more precise and efficient control.

Understanding the Trade-offs

Choosing the right boot involves balancing maximum protection with practical considerations.

Protection vs. Walkability

Generally, the more protective a boot is, the less comfortable it will be for walking. Full-length race boots offer the highest level of torsional rigidity and impact protection but are very stiff. Shorter, more casual-style riding shoes offer more flexibility but sacrifice some ankle protection.

The Myth of "Sturdy" Work Boots

While they may seem tough, standard work boots are a poor substitute for motorcycle boots. They lack torsional stiffness to protect against twisting and often have lug soles that can snag on footpegs. Most importantly, they are not designed to slide on pavement and can fail to protect you from abrasion.

The Critical Role of Proper Fit

A boot that is too loose cannot properly secure your ankle and may even come off in a crash. A boot that is too tight can create painful pressure points and restrict blood flow, becoming a dangerous distraction while riding. A snug, secure fit is essential for both comfort and safety.

Making the Right Choice for Your Goal

Your choice of boot should align directly with your primary type of riding.

- If your primary focus is maximum track-day protection: Choose a tall boot with extensive external armor, replaceable sliders, and a dedicated ankle-bracing system.

- If your primary focus is daily commuting or urban riding: Look for a certified riding shoe or short boot that offers reinforced ankle, toe, and heel protection with more off-bike comfort.

- If your primary focus is long-distance touring or adventure riding: Prioritize a boot that balances robust protection with weatherproofing and all-day comfort for long hours in the saddle.

Investing in proper motorcycle boots is a direct investment in your control and survival on the road.

Summary Table:

| Safety Feature | Protection Provided | Key Materials/Design |

|---|---|---|

| Abrasion Resistance | Withstands road slide forces | Full-grain leather, reinforced stitching |

| Impact & Crush Protection | Absorbs direct impact energy | Reinforced toe box, hardened heel counter, armor plates |

| Twist & Hyper-Extension Prevention | Reduces ankle fractures and ligament damage | Torsional stiffness, tall rigid construction |

| Enhanced Rider Control | Improves grip and precise control inputs | Non-slip soles, stiff construction for brake/shifter feedback |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety-certified motorcycle boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of riding footwear, from high-protection race boots to comfortable urban riding shoes. We ensure every pair meets rigorous safety standards with durable materials, reinforced armor, and superior grip soles.

Protect your customers with boots engineered for survival and control. Contact us today to discuss your specific needs and leverage our manufacturing expertise for your footwear line.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the available thickness options for the neoprene hunting shoes and boots? Choose for Warmth or Mobility

- What should be considered when choosing winter cycling boots for commuting? Find Your Perfect Fit for a Warm, Dry Ride

- What are the benefits of rubber hunting boots? Unmatched Waterproofing & Scent Control

- What is the technical value of TENG sensors in smart sports footwear? Revolutionize Energy & Biomechanical Data

- What new technologies are emerging in winter cycling shoes? Stay Warm & Dry with Advanced Heating & Fit Systems

- What additional features do dirtbike boots have for the left boot? Key Design for Shifting & Protection

- What are the common types of soles for winter boots? Find the Perfect Grip for Your Winter

- What distinguishes snow boots from snowboard boots? Choose the Right Winter Footwear for Safety & Performance