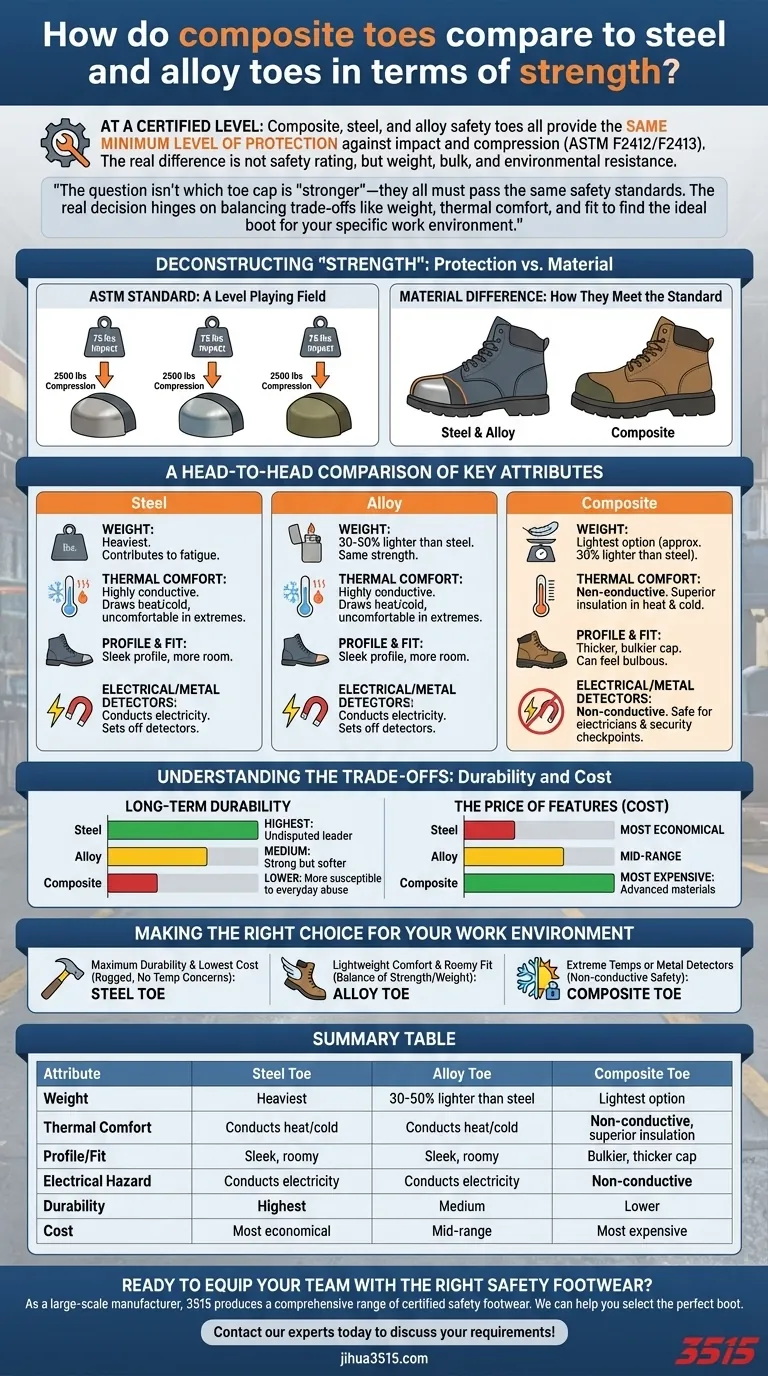

At a certified level, composite, steel, and alloy safety toes all provide the same minimum level of protection against impact and compression. The real difference is not in their safety rating, but in how the properties of each material affect the weight, bulk, and environmental resistance of the footwear.

The question isn't which toe cap is "stronger"—they all must pass the same safety standards. The real decision hinges on balancing trade-offs like weight, thermal comfort, and fit to find the ideal boot for your specific work environment.

Deconstructing "Strength": Protection vs. Material

To compare safety toes accurately, we must separate the concept of a safety standard from the inherent properties of the material used.

The ASTM Standard: A Level Playing Field

All legitimate safety footwear in the United States must meet standards set by ASTM International (F2412/F2413). This means they are tested to withstand the same forces.

Whether it's made of steel, alloy, or composite, a certified toe cap must protect you from a specific level of impact (e.g., 75 pounds dropped from a certain height) and compression (e.g., 2,500 pounds of rolling pressure).

The Material Difference: How They Meet the Standard

The materials achieve this certified protection in different ways.

Steel and alloy are extremely dense and strong. They can meet the standard with a relatively thin cap, resulting in a less bulky boot profile.

Composite materials (like carbon fiber, Kevlar, or plastic) are not as inherently strong as metal. To provide the same level of certified protection, the toe cap must be made with more material, resulting in a thicker, bulkier shape.

A Head-to-Head Comparison of Key Attributes

Beyond the safety rating, each material offers a distinct set of advantages and disadvantages that directly impact your daily comfort and performance.

Weight: The Burden on Your Feet

Steel is the traditional, heaviest option. Over a long day, this extra weight can contribute to fatigue.

Alloy toes, typically made from materials like aluminum or titanium, are a lighter alternative, weighing 30-50% less than steel while offering the same strength.

Composite toes are also significantly lighter than steel, often by about 30%. They are generally considered the lightest option available.

Thermal Comfort: Resisting Heat and Cold

This is where composite materials have a decisive advantage.

Metals like steel and alloy are highly conductive. In cold weather, they draw heat away from your feet, and in hot weather, they can absorb and retain heat, causing significant discomfort.

Composite toes are non-conductive. They provide superior insulation, keeping your feet more comfortable in both extreme heat and extreme cold.

Profile and Fit: The "Bulk Factor"

Because they are so strong, steel and alloy toes can be made thinner. This results in a sleeker boot profile and often provides more room inside the toe box.

As mentioned, composite toe caps must be thicker and bulkier to meet the same safety standards, which can make the end of the boot feel more bulbous or cramped for some users.

Electrical Hazards & Metal Detectors

Steel and alloy are metals and will conduct electricity. They will also set off metal detectors.

Composite toes are non-metallic and non-conductive. This makes them the only choice for electricians or workers who frequently pass through security checkpoints.

Understanding the Trade-offs: Durability and Cost

No single material is perfect; choosing one involves accepting its inherent compromises.

Long-Term Durability

Steel is the undisputed leader in durability. It can withstand more scrapes, bumps, and general wear-and-tear than the other materials.

Alloy toes offer medium durability. They are strong but generally softer than steel.

Composite toes have the lowest durability. While they provide excellent protection from a major impact, they are more susceptible to damage from everyday worksite abuse.

The Price of Features

The cost of the raw materials and manufacturing process directly impacts the final price of the boot.

Steel toes are the most economical option due to simple, established manufacturing processes.

Alloy toes fall in the middle of the price range.

Composite toes are typically the most expensive, reflecting the higher cost of the advanced materials used.

Making the Right Choice for Your Work Environment

Selecting the best safety toe is about matching the material's properties to your job's demands.

- If your primary focus is maximum durability at the lowest cost: Steel toe is the classic, reliable choice that excels in rugged environments where weight and temperature are not major concerns.

- If your primary focus is lightweight comfort with a roomy fit: Alloy toes offer a great balance, providing the strength of steel at a fraction of the weight without the bulk of composites.

- If your primary focus is working in extreme temperatures or passing through metal detectors: Composite toe is the clear and superior option, providing non-conductive safety and comfort.

Ultimately, choosing the right safety toe is about selecting the correct tool for your specific job and environment.

Summary Table:

| Attribute | Steel Toe | Alloy Toe | Composite Toe |

|---|---|---|---|

| Weight | Heaviest | 30-50% lighter than steel | Lightest option |

| Thermal Comfort | Conducts heat/cold | Conducts heat/cold | Non-conductive, superior insulation |

| Profile/Fit | Sleek, roomy | Sleek, roomy | Bulkier, thicker cap |

| Electrical Hazard | Conducts electricity | Conducts electricity | Non-conductive |

| Durability | Highest | Medium | Lower |

| Cost | Most economical | Mid-range | Most expensive |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can help you select the perfect boot—whether it's lightweight alloy for all-day comfort, durable steel for rugged conditions, or non-metallic composite for extreme temperatures and electrical safety.

Let us provide the durable, comfortable, and job-specific footwear your workforce needs.

Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management