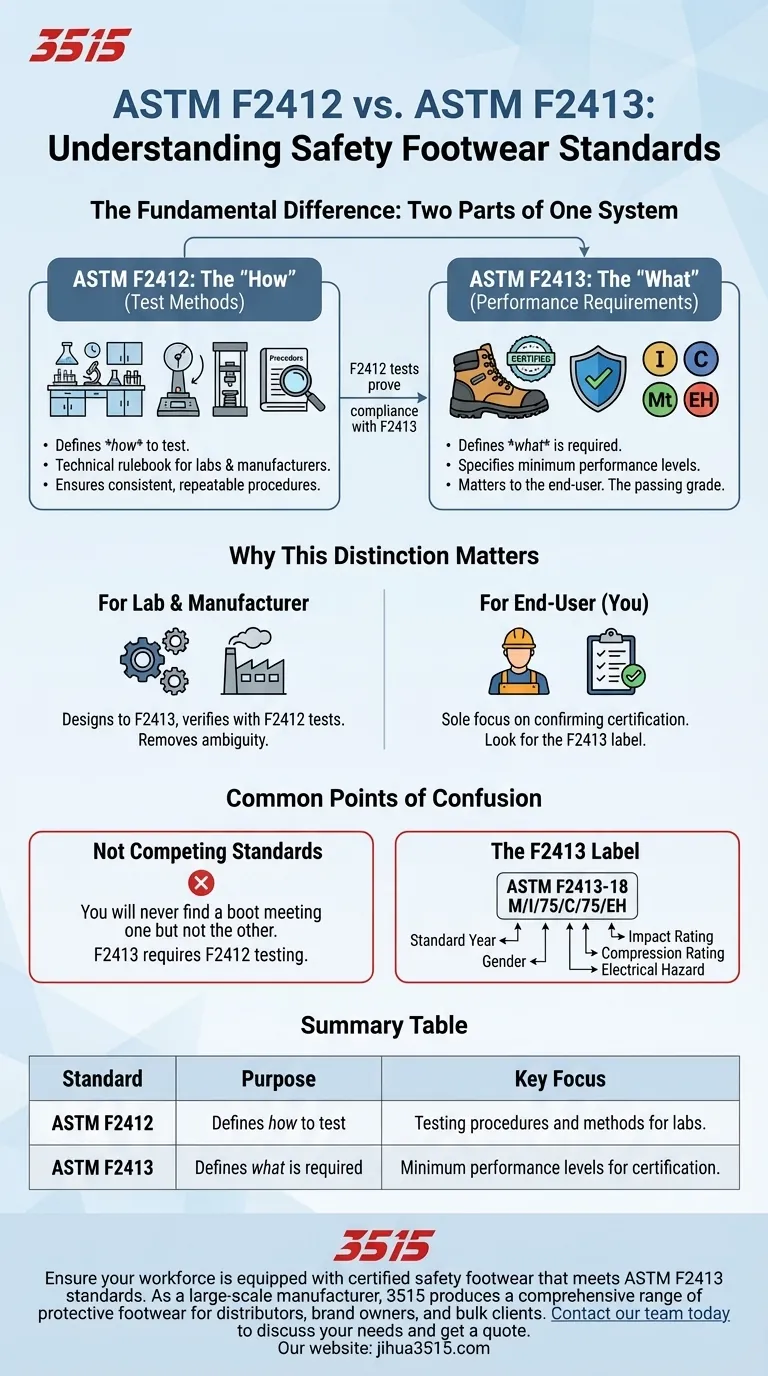

The fundamental difference is that ASTM F2412 defines how to test safety footwear, while ASTM F2413 specifies the minimum performance requirements the footwear must meet. These are not competing standards you choose between; they are two parts of a single system that work together. A boot is tested using the F2412 methods to prove it complies with the F2413 standard.

Think of it this way: ASTM F2412 is the instruction manual for the exam, while ASTM F2413 is the passing grade. For anyone buying or wearing safety footwear, you only need to confirm that the boot meets the ASTM F2413 standard.

The Role of Each Standard

To understand why this distinction is critical, it's helpful to see them as two sides of the same coin: the test and the result.

ASTM F2412: The "How" (Test Methods)

This standard is the technical rulebook for testing laboratories and manufacturers. It provides the exact, repeatable procedures for evaluating footwear.

ASTM F2412 details the specific equipment, conditions, and methods for conducting tests. This includes how to perform impact tests on the toe cap and how to apply force for compression testing.

Essentially, this standard ensures that a boot tested in one facility is evaluated the same way as a boot tested in another, guaranteeing consistency.

ASTM F2413: The "What" (Performance Requirements)

This is the standard that matters to the end-user. It outlines what constitutes a "safety shoe" and establishes the minimum criteria for protection.

ASTM F2413 defines the required performance for features like impact resistance (I), compression resistance (C), metatarsal protection (Mt), and electrical hazard resistance (EH).

When a boot has an ASTM F2413 label, it serves as a certification. It means the footwear was subjected to the tests defined in F2412 and successfully met or exceeded the minimum safety requirements.

Why This Distinction Matters

Separating the "how" from the "what" creates a clear and reliable system for everyone involved in the safety footwear lifecycle.

For the Lab and Manufacturer

A manufacturer designs a boot to meet the F2413 requirements. They then send it to a lab that uses the F2412 methods to verify its performance. This separation removes ambiguity from the process.

For the End-User (You)

As a worker or safety manager, you don't need to know the specifics of how the tests are performed. Your sole focus is confirming that the footwear is certified.

The presence of the ASTM F2413 tag inside the boot is your guarantee of compliance and protection.

Common Points of Confusion

The relationship between these standards is often misunderstood, leading to incorrect assumptions about safety.

They Are Not Competing Standards

You will never find a boot that meets F2412 but not F2413, or vice-versa. A boot cannot be certified to F2413 without having first passed the tests described in F2412.

The idea that a boot should "meet both" is technically true but misleading. The F2413 label is the only thing that proves this has occurred.

What the F2413 Label Tells You

The label itself provides specific information. A typical label might read: ASTM F2413-18 M/I/75/C/75/EH.

This code indicates the boot meets the 2018 version of the standard for a male (M), has the highest rating for impact (I/75) and compression (C/75), and is rated for electrical hazard (EH) protection.

Making the Right Choice

Your required level of engagement with these standards depends entirely on your role.

- If you are a safety manager or footwear manufacturer: You must be familiar with both standards to ensure product compliance and proper testing protocols.

- If you are buying or wearing safety boots: You only need to look for the ASTM F2413 label inside the footwear to confirm it is certified.

Ultimately, focusing on the F2413 certification is the simplest and most reliable way to ensure you have the protection you need.

Summary Table:

| Standard | Purpose | Key Focus |

|---|---|---|

| ASTM F2412 | Defines how to test | Provides the testing procedures and methods for labs and manufacturers. |

| ASTM F2413 | Defines what is required | Specifies the minimum performance levels a boot must meet for certification. |

Ensure your workforce is equipped with certified safety footwear that meets ASTM F2413 standards.

As a large-scale manufacturer, 3515 produces a comprehensive range of protective footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, ensuring durability, comfort, and compliance.

Let us help you source reliable safety footwear. Contact our team today to discuss your needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- Why is it necessary for safety boots designed for livestock environments to possess moisture-resistant properties?

- What factors should be considered when choosing the appropriate type of safety footwear? A Guide to Maximum Protection

- Why is chemical-resistant and waterproof footwear essential for manual car wash operations? Ensure Worker Safety

- Why is it important to maintain work shoes properly? Protect Your Safety and Investment

- What are the technical and construction advantages of professional-grade Safety Shoes? Enhance Stability and Grip

- How do oilfield safety shoes contribute to worker productivity? Boost Focus & Reduce Fatigue

- What are the key OSHA regulations for safety footwear? Ensure Compliance & Protect Your Workforce

- How has safety footwear evolved over time? From Wooden Sabots to Smart Boots