The defining innovation of the M-1942 jungle boot was its active ventilation system, centered around a unique woven mesh insole. This system was engineered to combat the primary cause of foot ailments in the tropics: trapped moisture. By creating a mechanism for air exchange with every step, it kept soldiers' feet dramatically drier and healthier than any previous standard-issue footwear.

The M-1942's true advantage was not just its ability to let water out, but its ingenious design that used the soldier's own movement as a pump. This active air circulation was the key to preventing the debilitating foot conditions common in jungle warfare.

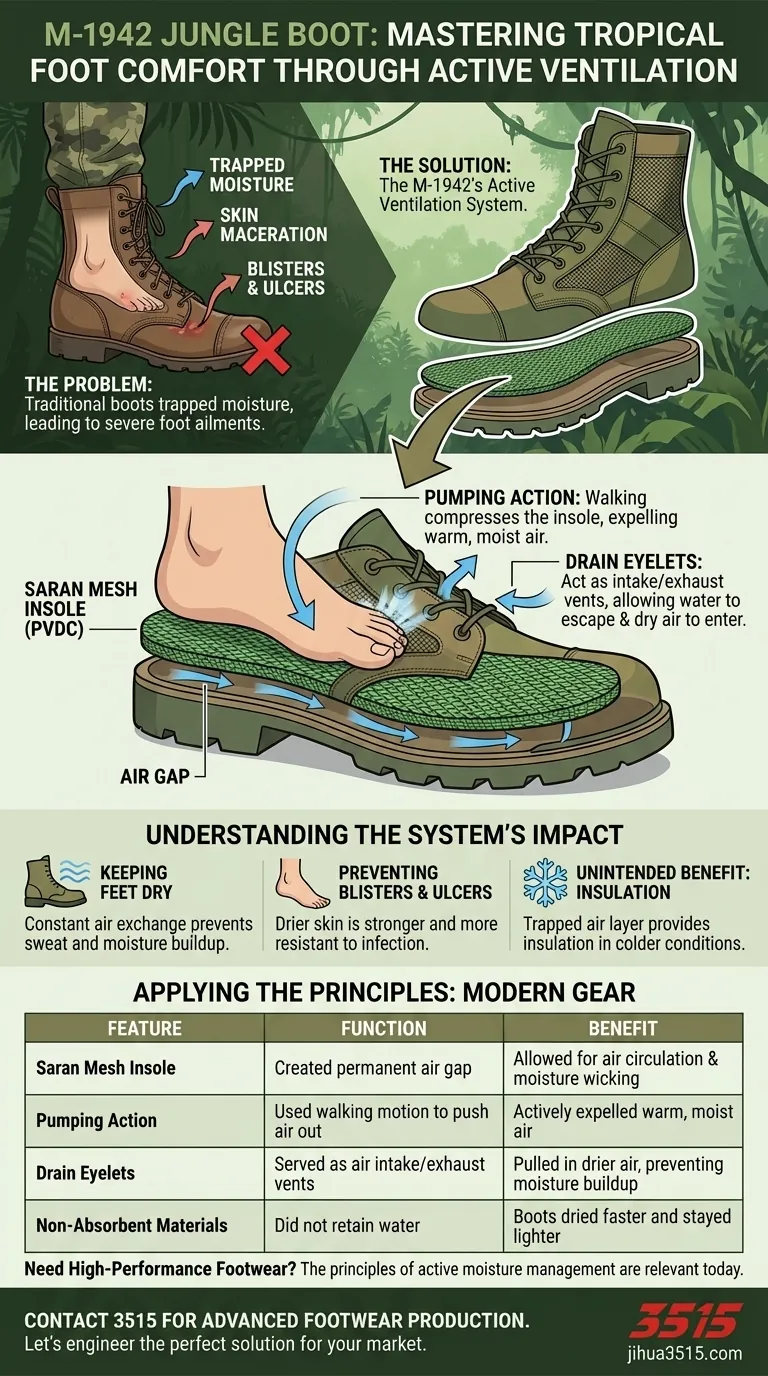

The Core Problem: Trapped Moisture in the Jungle

The Failure of Traditional Boots

Standard-issue leather boots were a liability in tropical environments. Once soaked, they became heavy, failed to dry, and trapped water against the skin. This constant moisture created the perfect conditions for severe foot problems.

The Medical Consequences

Prolonged exposure to moisture leads to skin maceration, where the skin becomes soft and weak. This dramatically increases the risk of painful blisters and the development of tropical ulcers, severe infections that could incapacitate a soldier.

Deconstructing the M-1942's Ventilation System

The Saran Mesh Insole

The heart of the system was an insole made from fused layers of Saran (PVDC) plastic woven into a mesh. This material was non-absorbent and created a permanent air gap between the bottom of the foot and the boot's sole.

The Pumping Action of Walking

This trapped layer of air was not static. As a soldier walked, the compression and release of the insole acted like a bellows. Each step squeezed moist, warm air out from inside the boot.

The Role of the Drain Eyelets

The final piece of the system was a set of water drain eyelets near the instep. These ports served a dual purpose: they allowed standing water to escape quickly, but more importantly, they acted as the intake and exhaust vents for the air pump. Moist air was pushed out, and drier, ambient air was pulled in with every step.

Understanding the System's Impact

Keeping Feet Dry

By constantly exchanging the boot's internal, humid air for drier external air, the system prevented the buildup of sweat and moisture. This directly addressed the root cause of skin breakdown and fungal infections.

Preventing Blisters and Ulcers

Drier skin is stronger and more resistant to friction and infection. By maintaining a healthier skin environment, the M-1942 boot significantly reduced the incidence of blisters and the tropical ulcers that could form from minor cuts or abrasions on compromised skin.

An Unintended Benefit: Insulation

The same trapped layer of air that provided ventilation also offered a degree of insulation. In colder conditions, this air gap helped insulate the foot from the cold ground, showcasing the versatility of the design principle.

How to Apply This to Your Gear

The principles pioneered by the M-1942 continue to influence modern footwear design for extreme environments.

- If your primary focus is moisture management in hot, wet climates: Prioritize footwear with built-in drainage ports and non-absorbent materials that promote active ventilation, mirroring the M-1942's core function.

- If your primary focus is preventing blisters and skin breakdown: Recognize that keeping the skin dry is paramount, a lesson directly demonstrated by the boot's air-circulating insole and modern moisture-wicking socks.

Ultimately, the M-1942 boot serves as a masterclass in how solving the root cause of a problem—in this case, trapped moisture—can fundamentally change performance and well-being.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Saran Mesh Insole | Created a permanent air gap | Allowed for air circulation and moisture wicking |

| Pumping Action | Used walking motion to push air out | Actively expelled warm, moist air with every step |

| Drain Eyelets | Served as air intake/exhaust vents | Pulled in drier air, preventing moisture buildup |

| Non-Absorbent Materials | Did not retain water | Boots dried faster and stayed lighter than leather |

Need High-Performance Footwear for Demanding Environments?

The principles of active moisture management pioneered by the M-1942 are more relevant than ever. As a large-scale manufacturer, 3515 produces a comprehensive range of advanced footwear for distributors, brand owners, and bulk clients. We can integrate modern materials and ventilation technologies into durable boots and shoes designed for extreme conditions, ensuring superior comfort and foot health for your end-users.

Let's engineer the perfect solution for your market. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What are the essential steps for cleaning military boots? A Complete Guide to Preserve Your Gear

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What are the steps to clean suede military boots? A Complete Guide to Gentle, Effective Care

- What materials are commonly used to make combat boots? Discover the optimal blend for durability and performance.

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style