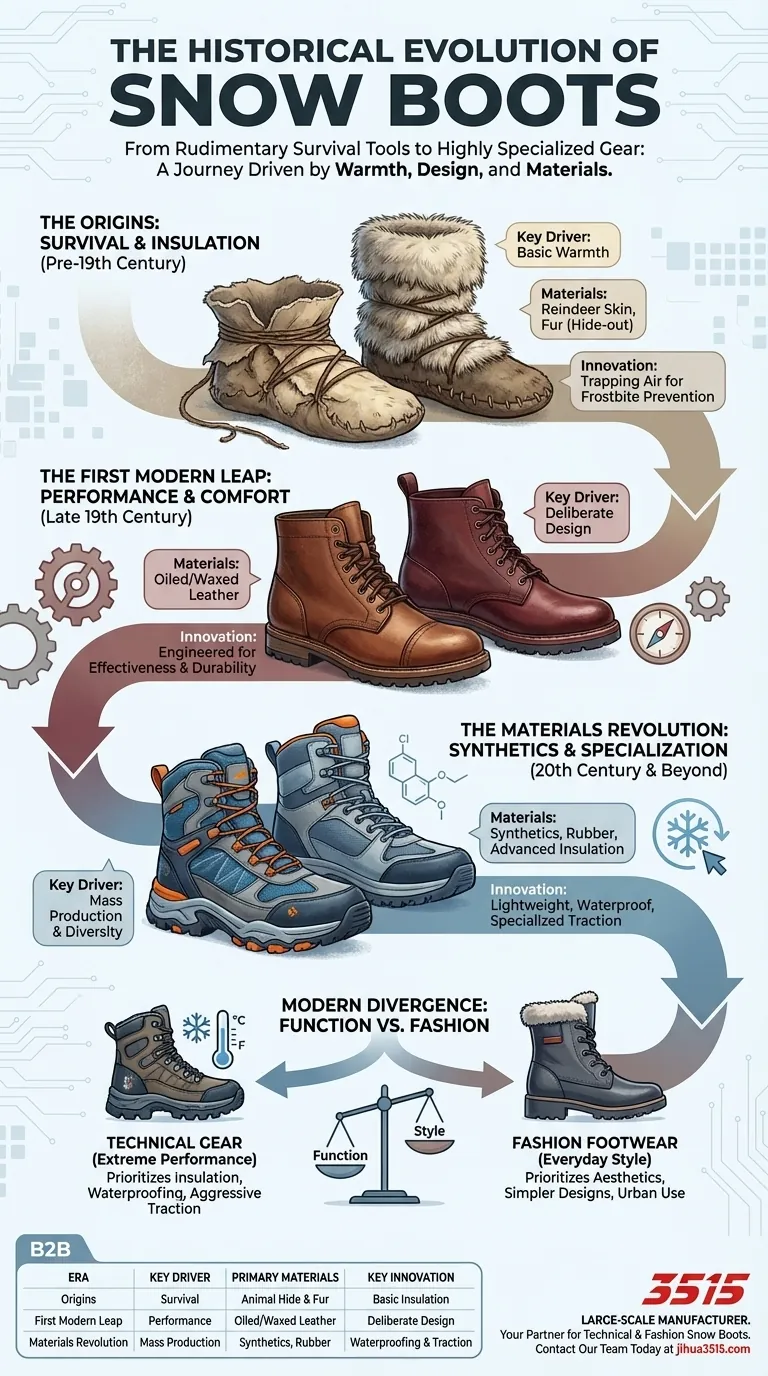

Historically, snow boots evolved from rudimentary survival tools made of animal hide into the highly specialized, engineered footwear we know today. This transformation was driven by three key factors: the need for basic warmth, the introduction of deliberate design for comfort and performance, and finally, the revolution in synthetic materials that allowed for mass production and stylistic diversity.

The evolution of the snow boot is a story about a shift in purpose. What began as a simple tool for survival has branched into distinct categories: highly technical gear for extreme performance and fashionable footwear for everyday winter life.

The Origins: A Focus on Pure Survival

The earliest forms of winter footwear were not designed; they were adapted. Their singular goal was to prevent frostbite and allow movement through deep snow.

### Early Materials and Purpose

The first snow boots were crafted from available natural resources. Peoples in arctic climates, for example, used reindeer skin and fur, turning it hide-out to create a durable, insulating wrap for the foot.

The primary function was insulation. These early boots trapped air and used the natural insulating properties of animal fur and hide to keep the wearer's feet from freezing.

### The Limits of Early Designs

While effective for their time, these early boots were fundamentally limited. They were often heavy, absorbed moisture over time, and lacked the structural support or specialized traction needed for varied icy or rocky terrain.

The First Modern Leap: Engineering for Performance

The concept of the "modern" snow boot emerged when footwear began to be intentionally engineered to solve specific problems beyond basic warmth.

### A Shift to Purpose-Built Design

In the late 19th century, the first modern snow boot was invented by a French doctor. This marked a critical turning point: the application of deliberate thought to improve both comfort and effectiveness.

This shift parallels the evolution of other functional footwear, like the army boot. Just as the Roman hobnailed sandal was refined over centuries into a piece of technical military gear, the snow boot started its journey from a simple wrap to a designed tool.

### Defining "Performance"

Early performance improvements focused on three areas: better insulation, the first attempts at waterproofing (using oils and waxes on leather), and more durable soles. The goal was to create a boot that could be worn longer, in wetter conditions, without failing.

The Materials Revolution: From Hide to Synthetics

The most dramatic changes in snow boot design occurred in the 20th century with the advent of new materials. This allowed for capabilities that were impossible with leather and fur alone.

### Moving Beyond Natural Materials

Today’s boots rely on synthetic fabrics, rubber shells, and advanced insulation. These materials offered huge advantages: they are significantly lighter, inherently waterproof, more durable, and suitable for mass production.

This leap in material science made high-performance, affordable winter footwear accessible to everyone, not just those living in extreme climates.

### The Birth of Specialized Traction

Modern materials also revolutionized the sole. Unlike a flat piece of hide, modern rubber and composite soles can be molded into complex lug patterns specifically designed to grip snow and ice. This concept of a feature engineered for a specific environmental interaction is also seen in riding boots, where the heel was historically shaped to prevent slipping from a stirrup.

Understanding the Trade-offs: Function vs. Fashion

As snow boots became more common and effective, their purpose began to diverge. They were no longer just for survivalists or mountaineers.

### The Influence of Culture

Much like the cowboy boot transformed from ranch equipment to a Hollywood fashion statement, the snow boot entered the world of style. Its adoption for casual urban and ski-resort wear created demand for boots that looked good, not just performed well.

### The Modern Compromise

This has resulted in a split market. Technical boots offer temperature ratings, advanced waterproofing, and aggressive traction for harsh conditions. Fashion boots, on the other hand, prioritize aesthetics, often using less insulation or simpler sole designs that are not intended for extreme weather.

Consumers must now be aware of this distinction. A stylish boot may not provide the protection needed for a true winter environment, creating a trade-off between form and function.

Making the Right Choice for Your Goal

Understanding this history empowers you to select a boot based on its intended purpose, not just its appearance.

- If your primary focus is extreme cold and deep snow: You need a technical boot prioritizing insulation ratings (like Thinsulate or PrimaLoft), a high cuff, and a waterproof membrane (like GORE-TEX).

- If your primary focus is icy urban commuting: Look for a boot with a modern rubber shell for waterproofing and a sole specifically engineered for grip on ice.

- If your primary focus is casual winter style: You have a wide array of options, but you must be conscious that you may be sacrificing high levels of warmth and traction.

Ultimately, knowing whether you need a tool for survival or an accessory for style is the key to finding the perfect winter boot.

Summary Table:

| Era | Key Driver | Primary Materials | Key Innovation |

|---|---|---|---|

| Origins | Survival & Insulation | Animal Hide & Fur | Basic foot protection from frostbite |

| First Modern Leap | Performance & Comfort | Oiled/Waxed Leather | Deliberate design for effectiveness |

| Materials Revolution | Mass Production & Specialization | Synthetics, Rubber, Advanced Insulation | Waterproofing, lightweight construction, specialized traction |

Need High-Quality Winter Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of technical and fashion snow boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated, waterproof, and high-traction footwear, ensuring you get the right product for your target customers' needs—whether for extreme performance or everyday winter style.

Let's discuss your next order: Contact our team today to learn more about our capabilities and how we can help you succeed.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What is the purpose of the heel collar in a walking shoe? Enhance Comfort & Stability

- How does a walking boot aid in recovery? Achieve Protected Mobility for Faster Healing

- Can running shoes be used for walking? Choosing the Right Footwear for Comfort & Support

- How do snake boots perform in colder temperatures? The Truth About Their Cold-Weather Failures

- How important is sole thickness and insulation for winter boots? Master Cold-Weather Comfort & Safety

- What are the features of paddock or jodhpur boots? Essential Equestrian Footwear Explained

- How does sole construction contribute to warmth in winter boots? The Key to All-Day Comfort

- How should one choose motorcycle boots based on riding style? Match Your Riding Discipline for Optimal Safety & Comfort