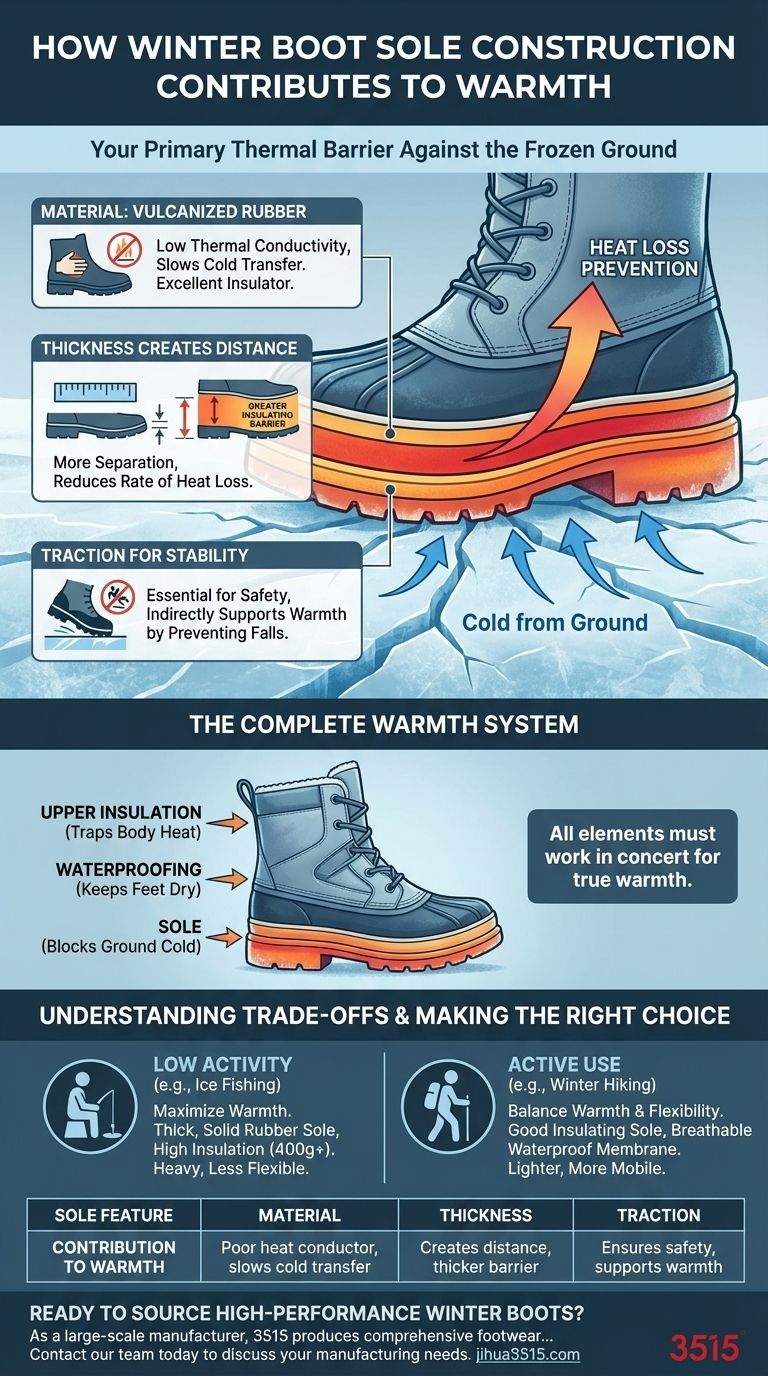

At its core, a winter boot's sole is your primary thermal barrier. Its main contribution to warmth is preventing the cold from the frozen ground from seeping into the boot and drawing heat away from your feet. This is achieved primarily through the use of specific materials and sufficient thickness to create an effective layer of insulation.

The sole of a winter boot acts as the foundation of its entire warmth system. While insulation in the upper part of the boot traps your body heat, the sole’s critical job is to block the intense, conductive cold coming directly from the ground you stand on.

The Sole as Your First Line of Defense

A boot's sole is in constant contact with snow, ice, and frozen pavement. Its construction is the first and most direct defense against the cold these surfaces hold.

The Critical Role of Material

The vast majority of quality winter boot soles are made from vulcanized rubber (with brands like Vibram being a common example). This material is chosen specifically for its low thermal conductivity.

Simply put, rubber is a poor conductor of heat, which makes it an excellent insulator. It slows the transfer of cold from the ground to your foot, preventing rapid heat loss.

Thickness Creates Distance

The thickness of the sole directly correlates with its insulating power. A thicker sole creates more physical distance and material between your foot and the cold ground.

This increased separation further reduces the rate of heat transfer, keeping the interior of the boot warmer for longer.

Traction for Stability

While not a direct feature of warmth, the sole's tread and slip-resistant properties are essential for a winter-ready boot. A deep, rugged tread provides stability on icy and snowy surfaces, which is a critical safety component of winter footwear.

Why the Sole is Only Part of the Equation

Thinking of a boot's warmth as a complete system is crucial. A highly insulating sole is rendered ineffective if the rest of the boot fails to manage heat and moisture properly.

Insulation: Trapping Body Heat

The insulation inside the upper part of the boot, often measured in grams (e.g., Thinsulate or PrimaLoft), is designed to trap the heat your body naturally generates. The sole prevents heat loss to the ground, while the upper insulation prevents heat loss to the cold air.

Waterproofing: The Enemy of Warmth

Moisture is the single biggest threat to staying warm. Wet feet lose heat up to 25 times faster than dry feet. A waterproof exterior is non-negotiable to prevent snow and slush from soaking the insulation and your socks.

The Complete System

For a boot to be truly warm, all three elements must work in concert. The sole insulates from the ground, the upper insulation traps body heat, and the waterproofing keeps the entire system dry and functional.

Understanding the Trade-offs

Choosing the perfect winter boot often involves balancing competing features. What makes a boot exceptional in one scenario can be a drawback in another.

Warmth vs. Flexibility

An extremely thick, highly insulating sole provides maximum protection from the cold ground. However, this thickness can also make the boot heavy, stiff, and less comfortable for activities that require a lot of walking.

Waterproofing vs. Breathability

Completely waterproof materials like solid rubber are great at keeping water out, but they also trap sweat inside. This can lead to damp feet that eventually get cold. Many modern boots use breathable waterproof membranes to manage this trade-off.

Your Activity Level Matters

The amount of heat your body produces varies with activity. A boot designed for stationary activities like ice fishing will have a very high insulation rating that would be far too warm and cause excessive sweating during an active winter hike.

Making the Right Choice for Your Goal

Select a boot by matching its sole construction and overall design to your primary winter activity.

- If your primary focus is maximum warmth for low activity: Prioritize boots with thick, solid rubber soles and a high insulation rating (400 grams or more) in the uppers.

- If your primary focus is active use like winter hiking: Look for a boot that balances a good insulating rubber sole with a more flexible design and a breathable, waterproof membrane.

- If your primary focus is casual daily wear and commuting: A moderately insulated, waterproof boot with a sole that provides excellent traction without being overly bulky is your ideal choice.

Ultimately, understanding how each part of the boot works together empowers you to choose footwear that truly protects you from the cold.

Summary Table:

| Sole Construction Feature | Contribution to Warmth |

|---|---|

| Material (e.g., Vulcanized Rubber) | Acts as a poor heat conductor, slowing the transfer of cold from the ground. |

| Thickness | Creates distance and a thicker insulating barrier between your foot and the cold surface. |

| Traction & Stability | Ensures safety on ice and snow, indirectly supporting warmth by preventing slips and falls. |

Ready to Source High-Performance Winter Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated, waterproof boots designed with the precise sole construction and material science detailed above to ensure superior warmth and durability.

Let us help you build a winter boot line that your customers will trust. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What makes Chelsea boots unique? The Iconic Blend of Style, Comfort, and Versatility

- Why is breathability important in walking shoes? Prevent Blisters & Odor for Comfortable Walks

- What features define walking shoes with the best arch support? A System for Pain-Free Movement

- How can the correct size for children's winter boots be determined? Ensure Warmth and Comfort with a Perfect Fit

- What methods can help break in new riding boots more quickly? Achieve a Custom Fit in Less Time

- What DIY snake-proof material suggestions were proposed? Why Experts Advise Against Them

- Why might someone consider replacing the insoles in their walking shoes? Boost Comfort & Extend Shoe Life

- What are the main differences between wellington boots and walking boots? Choose the Right Footwear for Your Activity