To restore shine and integrity to your rubber boots, you must first clean them thoroughly with warm water, then apply a specialized rubber conditioner or a small amount of olive oil using a soft, dry cloth. This process not only improves the aesthetic finish but seals the porous rubber material against environmental damage and drying.

Rubber is a natural material that eventually dries out and cracks without moisture. Regular conditioning does not just add a cosmetic shine; it replenishes the oils in the rubber to maintain flexibility and waterproofing capabilities.

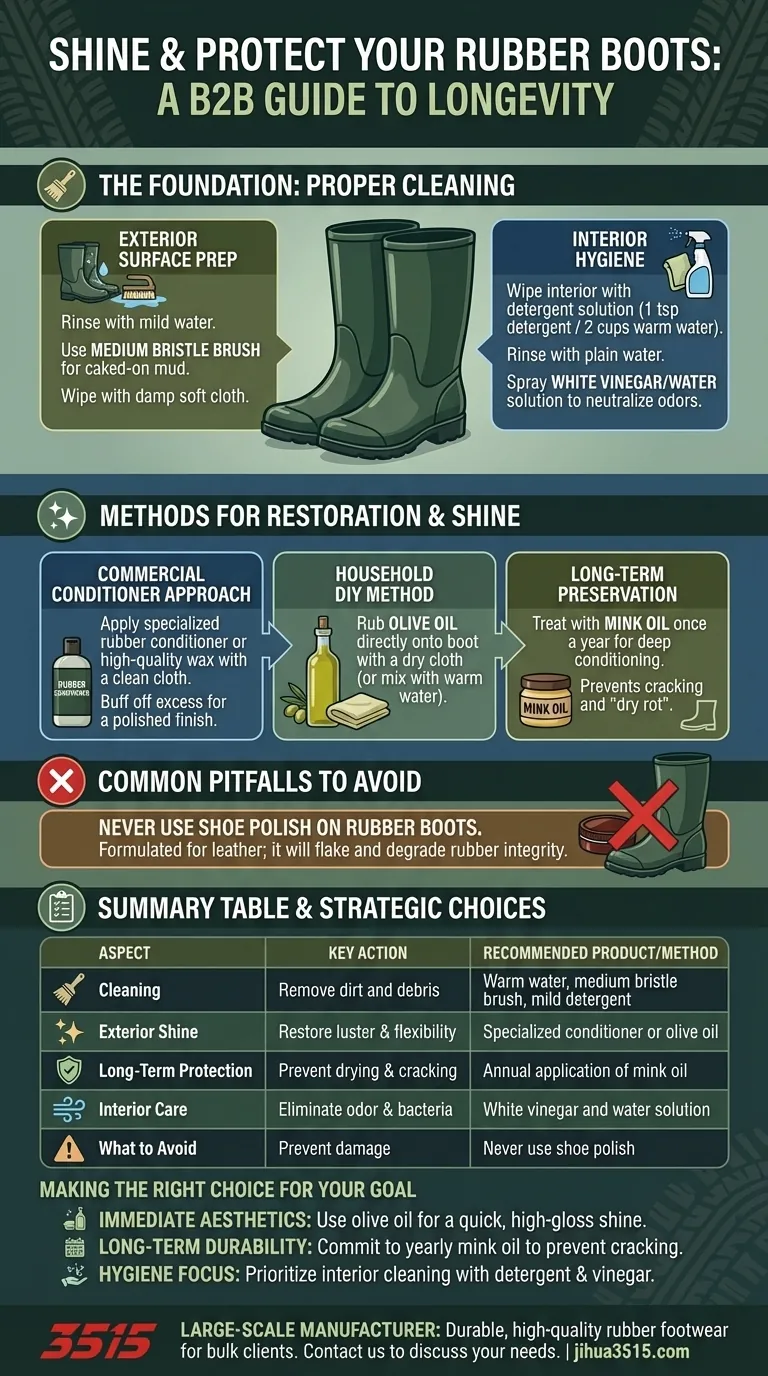

The Foundation: Proper Cleaning

Before applying any protectant, you must remove abrasive debris. Applying wax or oil over dirt will trap grit, which can degrade the rubber over time.

Exterior Surface Preparation

Start by rinsing the boots with mild water to remove loose dust and surface dirt.

For caked-on, dried mud, use a medium bristle brush. This mechanical action breaks up hardened layers without scarring the rubber.

Finish by wiping the boots down with a soft cloth or towel dampened with warm water to remove any remaining fine grime.

Interior Hygiene

The inside of the boot requires attention to prevent bacterial breakdown and odor.

Mix one teaspoon of heavy-duty laundry detergent with two cups of warm water. Wipe the interior lining thoroughly with a cloth soaked in this solution.

Follow this by wiping with a second cloth soaked in plain warm water to rinse. To neutralize odors, spray a solution of white vinegar and water inside the boot and allow it to air dry.

Methods for Restoration and Shine

Once the boots are clean and dry, you have several options to restore their luster and flexibility.

The Commercial Conditioner Approach

For the most reliable protection, apply a dedicated rubber conditioner or a high-quality wax.

Using a clean cloth, work the conditioner over the entire surface of the boot. Buff off any excess liquid to leave a polished, non-greasy finish.

The Household DIY Method

If you do not have specialized products, olive oil is an effective alternative.

You can rub olive oil directly onto the boot with a dry cloth, or mix it with warm water for a lighter application. This natural oil moisturizes the rubber, providing an immediate shine.

Long-Term Preservation

To extend the lifespan of the boots significantly, deep conditioning is required.

Treat the boots with mink oil once a year. This heavier treatment penetrates deeper than standard conditioners, keeping the rubber supple and preventing the dreaded "dry rot" or cracking that occurs with age.

Common Pitfalls to Avoid

While maintaining rubber is straightforward, using the wrong products can cause irreversible damage.

The Shoe Polish Error

Never use shoe polish on rubber boots.

Shoe polish is formulated for tanned leather. On rubber, it will not absorb properly; instead, it will sit on the surface, flake off, and potentially degrade the structural integrity of the rubber itself.

Making the Right Choice for Your Goal

Select your maintenance method based on whether you need a quick cosmetic fix or long-term durability.

- If your primary focus is immediate aesthetics: Use the olive oil and dry cloth method to quickly achieve a high-gloss shine before heading out.

- If your primary focus is long-term durability: Commit to a yearly application of mink oil to prevent cracking and maintain the waterproof seal.

- If your primary focus is hygiene: Prioritize the interior cleaning regimen with detergent and vinegar to prevent mold and odor buildup.

Regular maintenance is the difference between boots that last a season and boots that last a lifetime.

Summary Table:

| Aspect | Key Action | Recommended Product/Method |

|---|---|---|

| Cleaning | Remove dirt and debris | Warm water, medium bristle brush, mild detergent |

| Exterior Shine | Restore luster and flexibility | Specialized rubber conditioner or olive oil |

| Long-Term Protection | Prevent drying and cracking | Annual application of mink oil |

| Interior Care | Eliminate odor and bacteria | White vinegar and water solution |

| What to Avoid | Prevent damage | Never use shoe polish on rubber |

Need Durable, High-Quality Rubber Boots That Are Easy to Maintain?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable rubber boots designed for longevity and performance, making maintenance simple.

Contact us today to discuss your bulk footwear needs and discover how we can provide reliable, high-quality solutions for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries