To manually help break in your boots, you should repeatedly and firmly bend them at their natural flex points. Focus your efforts on the ankle area and the ball of the foot, as these are the primary spots that need to loosen for a comfortable stride. This process helps relax the stiff leather fibers, accelerating the a crucial part of the break-in period.

The core principle is simple: manual manipulation mimics the repetitive stress of walking. By working the leather when your feet aren't in the boots, you speed up the process of making them flexible and conforming to your movement.

Understanding How Leather Breaks In

New leather boots, particularly those made from thick, high-quality hides, are famously stiff. The break-in process is the journey from rigid discomfort to a custom-fit feel.

Why New Boots Are Stiff

The fibers in new leather are dense, tightly woven, and have not yet been subjected to significant stress or heat. This is what gives the boot its initial structure and durability.

The Goal: Flexibility and Fit

Breaking in a boot involves two key changes. First, you need to introduce flexibility at the points where your foot and ankle naturally bend. Second, the warmth and pressure from your foot slowly mold the leather to its unique contours.

How Manual Bending Helps

Manually flexing the boot directly targets the first goal: flexibility. By repeatedly bending the leather at the ankle and across the ball of the foot, you are physically loosening those dense fibers, making the material more pliable before it ever goes on your foot.

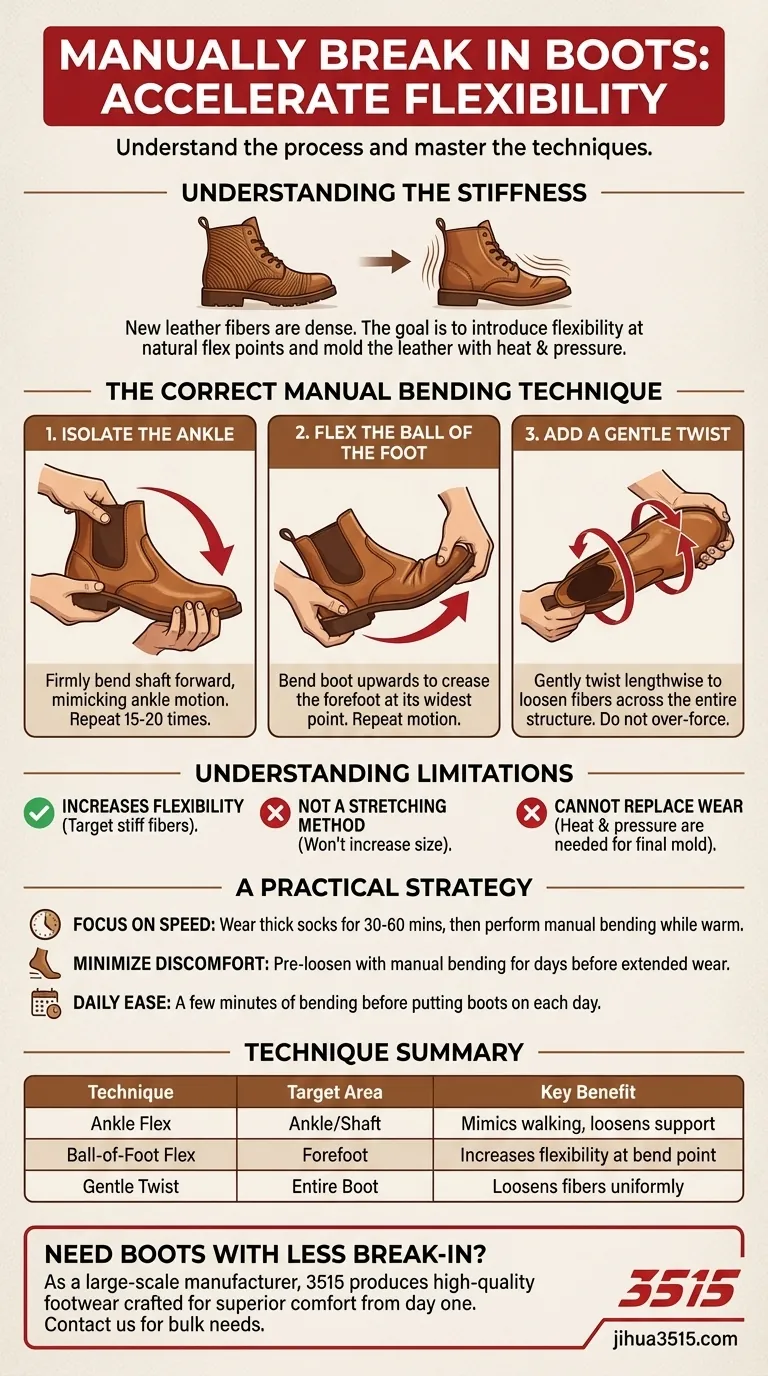

The Correct Manual Bending Technique

A few minutes of focused effort can make a significant difference. The best time to do this is often after you've worn the boots for a short period, as the leather will be slightly warmed up and more responsive.

Step 1: Isolate the Ankle

Hold the boot with one hand on the shaft and the other on the heel. Firmly bend the shaft forward towards the toe, mimicking the motion your ankle makes when you step forward. Release and repeat this motion about 15-20 times.

Step 2: Flex the Ball of the Foot

Grip the boot at the heel and toe. Bend the boot upwards, as if you were trying to fold it in half, causing a deep crease across the widest part of the forefoot (the ball). This directly works the area that flexes with every step you take. Repeat this motion as well.

Step 3: Add a Twist

Gently twist the boot lengthwise. This helps to loosen the fibers across the entire structure, not just at the primary bend points. Do not use excessive force; the goal is a gentle but firm manipulation.

Understanding the Limitations

Manual bending is a powerful supplement to the break-in process, but it is not a complete solution. It's crucial to know what it can and cannot do.

This Is Not a Stretching Method

Manual bending is for increasing flexibility. It will not make a boot that is too short or too narrow any larger. If the boot is painfully tight, you need a different solution, like a professional boot stretcher.

It Cannot Replace Actual Wear

The only way to get a boot to perfectly mold to the unique shape of your foot is by wearing it. The heat and pressure from your foot are essential for achieving that true custom fit. Manual bending accelerates the initial stiffness but doesn't complete the final molding process.

Avoid Using Excessive Force

The goal is to loosen the leather, not to damage it. Bending the boot in unnatural ways or with extreme force can create ugly, permanent creases or even weaken the leather's structure. Mimic natural movements.

A Practical Strategy for Comfort

Combine manual techniques with smart wear habits for the most efficient and comfortable break-in experience.

- If your primary focus is speed: Wear thick socks and walk around your house for 30-60 minute intervals. Immediately after, perform the manual bending routine while the leather is still warm and pliable.

- If your primary focus is minimizing discomfort: Focus on manual bending for several days before you even begin wearing the boots for extended periods. This pre-loosens the leather, reducing the pain of the initial wears.

- If your boots are just a little stiff: A few minutes of manual bending before you put your boots on each day can be enough to ease the leather into a comfortable state for the day's wear.

Ultimately, this technique gives you direct control over the most stubborn parts of a new boot, helping you reach that perfect fit faster.

Summary Table:

| Technique | Target Area | Key Benefit |

|---|---|---|

| Ankle Flex | Ankle/Shaft | Mimics walking motion, loosens ankle support |

| Ball-of-Foot Flex | Forefoot | Increases flexibility at the primary bend point |

| Gentle Twist | Entire Boot | Loosens fibers uniformly, prevents stiffness |

Need boots that require less breaking-in? As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure boots are crafted for superior comfort and durability from day one. Contact us today to discuss your footwear needs and benefit from our expertise in manufacturing all types of shoes and boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What attire is typically worn by dressage riders, and how do boots complement this? The Essential Guide to Performance Attire

- What is the significance of body weight sensor calibration for gait testing? Ensure High-Fidelity Biomechanical Data

- What materials combine durability with breathability? Find the Perfect Balance for Your Product

- Why is industrial-grade sandpaper meeting standards such as ISO 24 used in football shoe outsole grip field tests?

- What is the role of digital research tools in analyzing consumer behavior for green footwear products? Data-Driven ROI

- What are the key differences between factory-made and bespoke cowboy boots? Find Your Perfect Fit & Style

- Why might advanced track boots have lower certification levels? The Real-World Safety Paradox

- What are the technical advantages of using a parallel co-rotating twin-screw extruder? Master Nano-Silver Dispersion