Ensuring your winter boots remain waterproof is a two-part system. It begins with selecting a boot built with waterproof components from the start—such as internal membranes and sealed construction—and is maintained through a consistent regimen of cleaning and re-applying the correct protective treatments for your boot's material.

The most common mistake is treating waterproofing as a single action, like applying a spray. True, lasting protection comes from understanding that a boot's inherent design provides the foundation, while your maintenance routine preserves that defense against the elements.

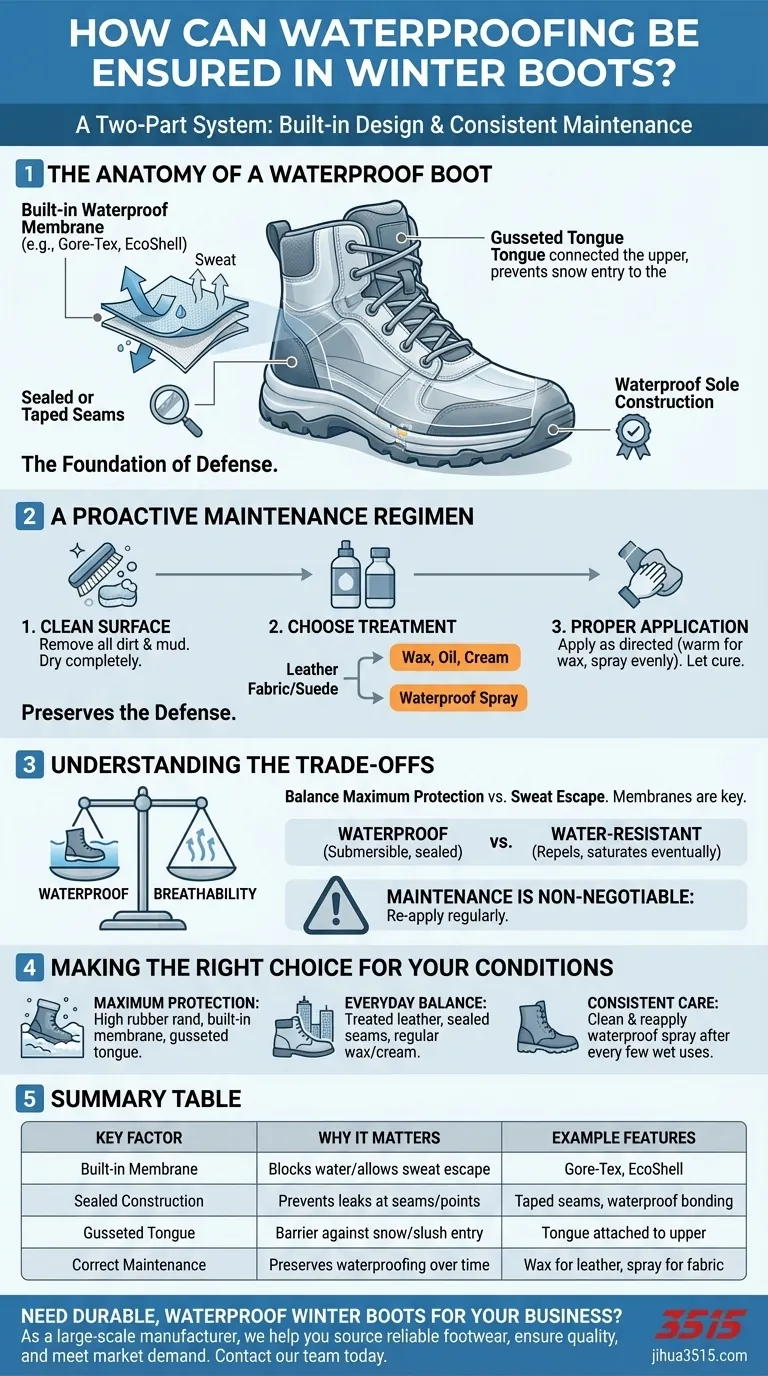

The Anatomy of a Waterproof Boot

Before you can treat a boot, you must understand what makes it waterproof in the first place. These are the structural features to look for when evaluating a boot's ability to keep water out.

Waterproof Materials & Membranes

The outer material is your first line of defense. Burly rubber and specially treated leathers offer significant protection.

However, the most reliable waterproofing comes from a built-in membrane, a waterproof and breathable layer sandwiched between the boot's outer material and its inner lining. Brands like Gore-Tex or EcoShell are engineered to block external moisture while allowing sweat vapor to escape.

Seam Sealing and Sole Construction

A boot's seams are its most vulnerable points for water entry. High-quality boots will have sealed or taped seams to prevent moisture from seeping through the stitching holes.

Pay attention to how the sole is attached. A direct-attached sole should have a waterproof seal at the join, while a sewn sole requires waterproof stitching to maintain its integrity.

The Role of the Gusseted Tongue

A gusseted tongue is a crucial feature for true waterproofing. This means the tongue is connected to the upper along the sides, creating a continuous barrier that blocks snow, slush, and water from entering through the lace area.

A Proactive Maintenance Regimen

Even the best-constructed boots require regular care. The factory's durable water repellent (DWR) coating wears off over time, and materials need to be reconditioned to maintain their performance.

Step 1: Start with a Clean Surface

You cannot waterproof dirt. Always begin by thoroughly cleaning your boots to remove any caked-on mud or debris. Use a stiff brush and, if necessary, a simple soap and water solution, then allow the boots to air dry completely.

Step 2: Choose the Right Treatment

The type of boot material dictates the correct product. Applying the wrong one can be ineffective or even damage the material.

- Waxes, Oils, or Creams: These are best for smooth leather boots. They soak into the leather to condition it and create a robust waterproof barrier.

- Waterproof Sprays: These are the correct choice for fabric, suede, or nubuck boots. They create a surface-level barrier without altering the material's texture.

Step 3: Proper Application Technique

For waxes or creams on leather, you can gently warm the boot with a hairdryer to help the leather absorb the treatment. Apply it evenly with a rag, wipe away any excess, and allow it to dry for several hours.

For fabric boots, apply the waterproof spray evenly from a short distance and let it cure completely as directed by the product instructions.

Understanding the Trade-offs

Achieving perfect waterproofing involves balancing competing factors. Understanding these trade-offs helps you select the right boot and set realistic expectations.

Waterproof vs. Water-Resistant

These terms are not interchangeable. Water-resistant means the boot can repel water to some degree, but will eventually get saturated. Waterproof implies the boot can be fully submerged to a certain depth without leaking, thanks to features like a membrane and sealed seams.

The Breathability Factor

The most significant trade-off is waterproofing versus breathability. A fully non-porous material, like rubber, is completely waterproof but also traps all sweat.

This is why breathable membranes are so valuable. They prevent your feet from getting wet from the inside out, which is a key cause of cold feet in the winter.

Maintenance is Non-Negotiable

No waterproofing treatment is permanent. Friction, dirt, and time all degrade the protective layer. Regular re-application is not an optional step; it is essential to the boot's long-term performance.

Making the Right Choice for Your Conditions

Your specific needs will determine which features and maintenance routines are most important.

- If your primary focus is maximum protection in deep snow or slush: Prioritize boots with a high rubber rand, a built-in waterproof membrane like Gore-Tex, and a fully gusseted tongue.

- If your primary focus is everyday winter use in a city: A treated leather boot with sealed seams offers a great balance of protection and style but will require regular re-application of a waterproofing wax or cream.

- If you own fabric or suede boots: Rely on a consistent routine of cleaning and reapplying a dedicated waterproof spray after every few uses in wet conditions to maintain their water resistance.

By understanding a boot's construction and committing to its care, you take full control over keeping your feet warm and dry all winter.

Summary Table:

| Key Factor | Why It Matters | Example Features |

|---|---|---|

| Built-in Membrane | Blocks water while allowing sweat to escape. | Gore-Tex, EcoShell |

| Sealed Construction | Prevents leaks at critical points like seams. | Taped seams, waterproof sole bonding |

| Gusseted Tongue | Creates a barrier against snow and slush entry. | Tongue attached to the boot's upper |

| Correct Maintenance | Preserves the boot's waterproofing over time. | Wax for leather, spray for fabric/suede |

Need Durable, Waterproof Winter Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof boots, engineered with the right membranes, construction, and materials to ensure long-lasting protection for end-users.

We help you:

- Source Reliable Footwear: Offer your customers boots built with proven waterproofing systems.

- Ensure Quality & Consistency: Benefit from our large-scale manufacturing expertise and rigorous quality control.

- Meet Market Demand: Provide the durable winter boots that consumers need.

Let's discuss your specific requirements. Contact our team today to explore how we can support your business with high-quality, waterproof footwear solutions.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How does the slip resistance of industrial safety shoes protect workers during Genset maintenance? Prevent Oil Slips

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection