Understanding the materials in a safety shoe is the single most important factor in choosing the right product. Different materials directly determine a shoe's protective capabilities, comfort, breathability, and durability, allowing you to match its specific features to the unique hazards of your work environment.

Choosing the right safety footwear is not about finding one "best" material. It's about understanding the specific performance trade-offs each material offers and selecting the combination that best solves the challenges of your specific job.

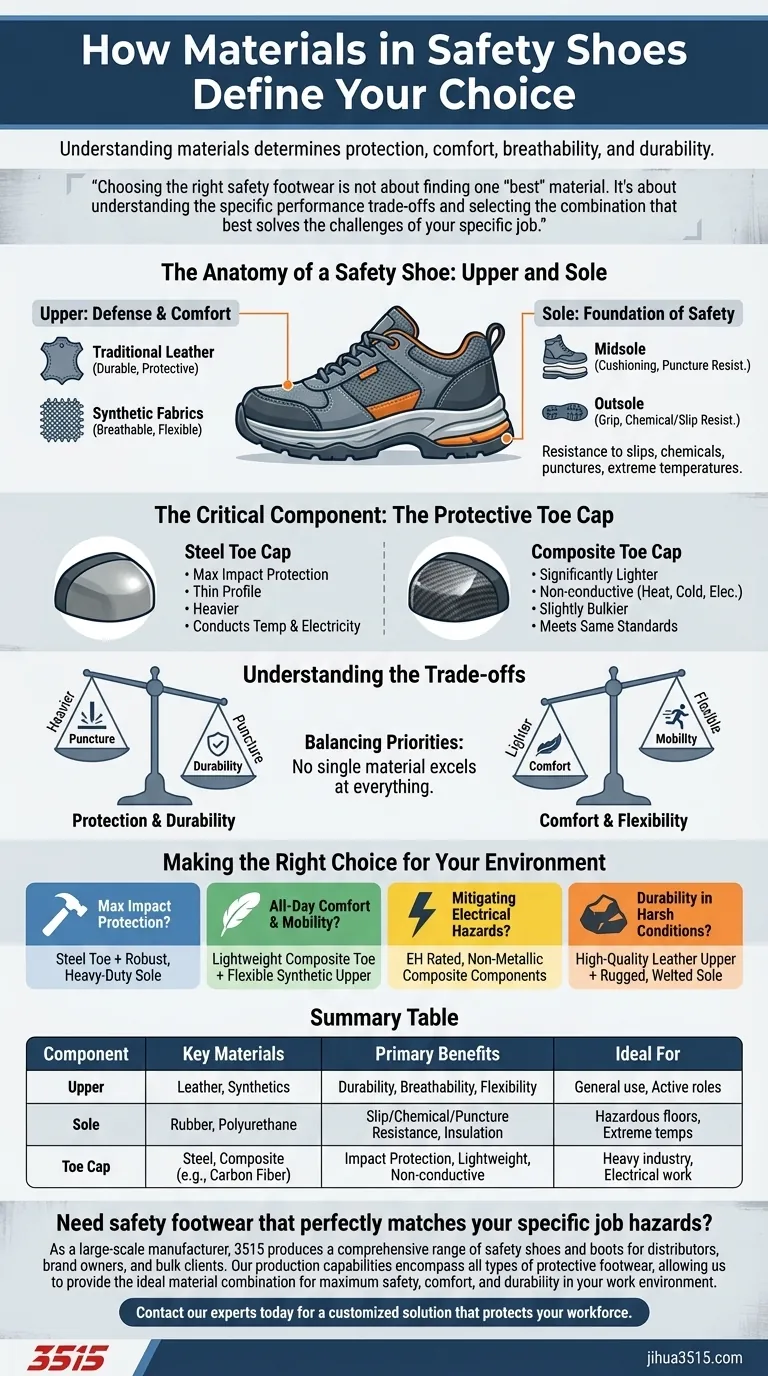

The Anatomy of a Safety Shoe: Upper and Sole

Every part of a safety shoe is built with a purpose, and the materials used in its construction define its performance. The two primary components to analyze are the upper and the sole.

The Upper: Your First Line of Defense and Comfort

The upper is the part of the shoe that covers your foot. Its material dictates breathability, flexibility, and resistance to environmental factors.

Materials are chosen for specific properties. For example, traditional leathers are known for their exceptional durability and protection, while modern synthetic fabrics can offer superior breathability and flexibility for active roles.

The Sole: The Foundation of Safety

The sole unit is a complex system, often with a midsole for cushioning and puncture resistance, and an outsole for grip and durability.

The sole's material composition is critical for protection against specific hazards. This includes resistance to slips, chemicals, and punctures, as well as providing insulation from extreme temperatures or electrical currents.

The Critical Component: The Protective Toe Cap

The defining feature of a safety shoe is its protective toe cap. Understanding the material used here is essential, as it directly impacts safety, weight, and comfort.

Material Properties Dictate Performance

The two most common types are steel and composite (like carbon fiber, Kevlar, or plastic). Steel caps offer maximum impact protection in a thin profile but are heavier and conduct temperature.

Composite caps are significantly lighter, do not conduct heat, cold, or electricity, and still meet the same safety standards. However, they may be slightly bulkier than steel to achieve the same impact rating.

Hazard-Specific Material Choices

Your work environment dictates the best material. If you work around live circuits, a non-metallic composite toe is non-negotiable to mitigate electrical hazards.

If you work in extreme cold or heat, a composite toe will provide far better insulation and comfort than a steel toe, which can transfer ambient temperatures directly to your foot.

Understanding the Trade-offs

Selecting the right material is always a matter of balancing competing priorities. There is no single material that excels at everything.

Protection vs. Comfort

Heavier, more robust materials generally offer greater protection against impacts and punctures. However, this often comes at the cost of increased weight and reduced flexibility, which can lead to fatigue over a long workday.

Durability vs. Flexibility

Tough, abrasion-resistant materials like full-grain leather provide exceptional durability for harsh environments. Synthetics and lighter materials may offer better flexibility and out-of-the-box comfort but may not withstand the same level of abuse over time.

General Purpose vs. Specialized Needs

A standard safety shoe is designed for general impact resistance. However, footwear engineered for specific risks—like electrical hazards, chainsaw protection, or foundry work—uses highly specialized materials that increase the cost.

Making the Right Choice for Your Environment

Assess your primary needs to narrow down the ideal material composition for your next pair of safety shoes.

- If your primary focus is maximum impact protection: Prioritize a shoe with a steel toe and a robust, heavy-duty sole construction.

- If your primary focus is all-day comfort and mobility: Look for shoes with lightweight composite toes and flexible synthetic uppers.

- If your primary focus is mitigating electrical hazards: You must choose footwear rated for EH protection, which will always feature non-metallic, composite components.

- If your primary focus is durability in harsh conditions: Select shoes with high-quality leather uppers and a rugged, welted sole designed for longevity.

By analyzing the materials, you transform your choice from a guess into a calculated decision that ensures both safety and comfort on the job.

Summary Table:

| Component | Key Materials | Primary Benefits | Ideal For |

|---|---|---|---|

| Upper | Leather, Synthetics | Durability, Breathability, Flexibility | General use, Active roles |

| Sole | Rubber, Polyurethane | Slip/Chemical/Puncture Resistance, Insulation | Hazardous floors, Extreme temps |

| Toe Cap | Steel, Composite (e.g., Carbon Fiber) | Impact Protection, Lightweight, Non-conductive | Heavy industry, Electrical work |

Need safety footwear that perfectly matches your specific job hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, allowing us to provide the ideal material combination for maximum safety, comfort, and durability in your work environment.

Contact our experts today for a customized solution that protects your workforce.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?