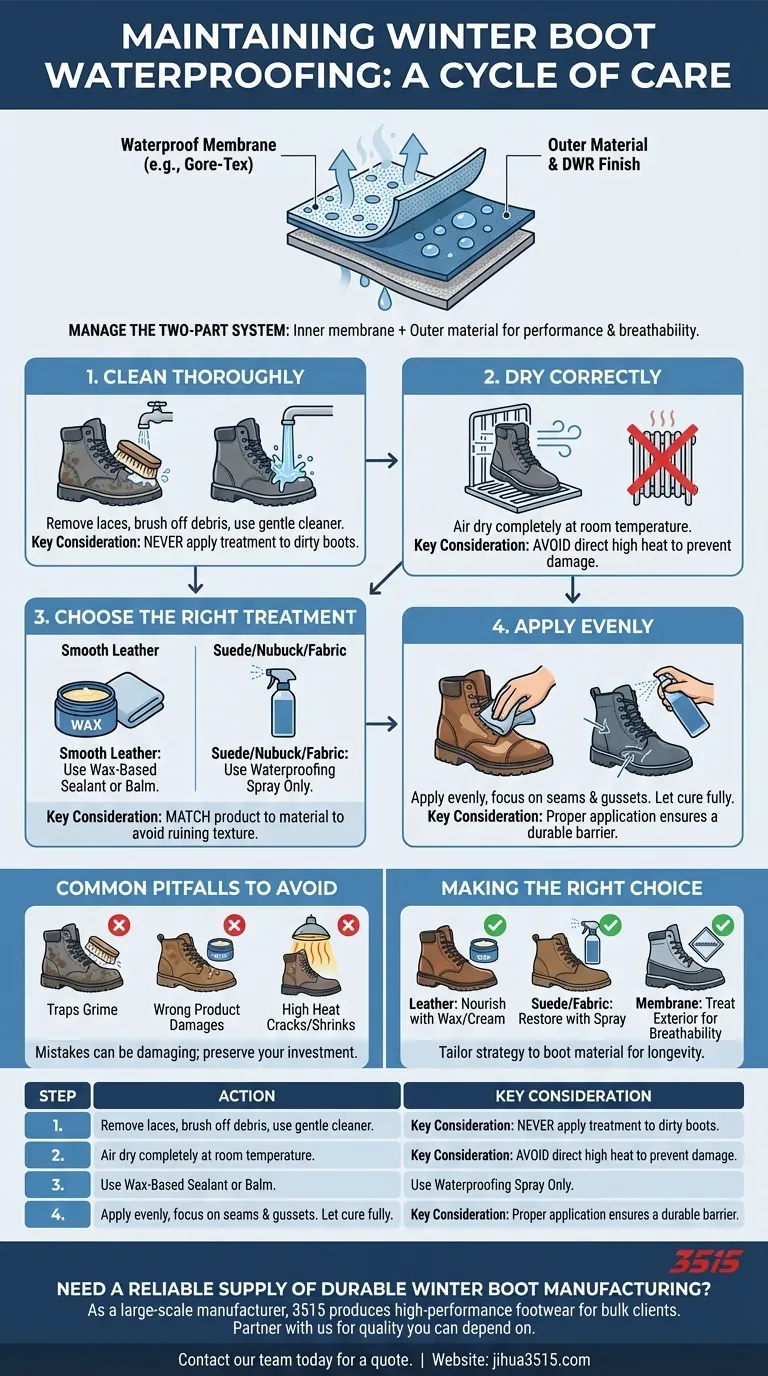

To properly maintain the waterproofing of your winter boots, you must adopt a simple but crucial cycle of care. This involves regularly cleaning the boots of all debris, allowing them to dry naturally, and then reapplying a waterproofing treatment specifically designed for your boot's material—typically a wax for smooth leather or a spray for suede and synthetic fabrics.

The core principle of winter boot maintenance is understanding that you are managing a two-part system. You are not just reapplying a water-repellent layer; you are preserving the performance of the boot's exterior material to allow the entire waterproof system, including any internal membranes, to function as designed.

Understanding Your Boot's Defense System

Effective waterproofing isn't just a single feature but a collaboration between different components. Maintaining it requires understanding how they work together.

The Inner Barrier: Waterproof Membranes

Many modern winter boots contain a built-in waterproof and breathable membrane, such as Gore-Tex or a manufacturer's proprietary equivalent.

This membrane is a high-tech layer sandwiched between the outer material and the inner lining. Its job is to block external water molecules from getting in while allowing smaller sweat vapor molecules to escape.

The Outer Shield: The Boot's Material

The exterior of your boot—be it leather, suede, or a synthetic fabric—serves as the first line of defense.

This material is often treated with a Durable Water Repellent (DWR) finish from the factory. This finish causes water to bead up and roll off rather than soak in.

Why Both Layers Matter

When the exterior DWR wears off, the outer fabric can become saturated with water, a state known as "wetting out."

Even if the inner membrane stops this water from reaching your foot, a wetted-out boot feels cold, heavy, and critically, it loses its breathability. The saturated outer layer prevents sweat from escaping, making your feet feel clammy and eventually cold.

The 4-Step Maintenance Process

Follow this procedure after any extensive use or whenever you notice water is beginning to soak into the outer material rather than beading up.

Step 1: Thoroughly Clean Your Boots

You cannot create an effective waterproof seal over dirt. Begin by removing the laces.

Use a stiff brush to remove all dried mud and caked-on debris. For stubborn dirt, use a rag with a gentle soap-and-water solution or a specialized footwear cleaner.

Step 2: Dry Them Correctly

Allow the boots to air dry completely at room temperature.

Do not place them next to a direct heat source like a radiator, fireplace, or vent. Intense heat can crack leather, melt adhesives, and permanently damage the boot's structure.

Step 3: Choose the Right Treatment

The product you use is dictated entirely by your boot's material.

- For smooth, full-grain leather: Use a wax-based sealant or conditioning balm. These products nourish the leather while creating a powerful waterproof barrier.

- For suede or nubuck: Only use a waterproofing spray. Waxes or creams will ruin the napped texture of the material.

- For synthetic/fabric boots: A waterproofing spray is the correct choice to recoat the material without affecting its flexibility or breathability.

Step 4: Apply the Treatment Evenly

For waxes, you can gently warm the leather with a hairdryer on a low setting. This opens the pores and helps the wax absorb more deeply. Apply it evenly with a clean rag.

For sprays, hold the can the recommended distance from the boot and apply a thin, even coat across the entire surface. Pay special attention to seams and the area where the sole joins the upper. Let the boots cure for the time specified by the product instructions.

Common Pitfalls to Avoid

Mistakes in the maintenance process can be ineffective at best and damaging at worst. Being aware of them is critical for preserving your investment.

Applying Treatment to Dirty Boots

Applying a waterproofing product over dirt simply traps the grime against the boot's material. This prevents the treatment from bonding properly and can accelerate the breakdown of the underlying fabric or leather.

Using the Wrong Product for the Material

This is the most common and damaging error. Using a heavy wax on suede will mat the fibers and stain them permanently. Using a light spray on burly leather may not provide a durable enough barrier. Always match the product to the material.

Force-Drying with High Heat

As mentioned, direct high heat is the enemy of modern footwear. It compromises the glues holding the boot together and can cause leather to shrink and crack, creating new entry points for water. Patience and air drying are essential.

Neglecting Seams and Gussets

Water's favorite entry points are areas of high stress and complex construction, like the seams and the tongue gusset (the material connecting the tongue to the boot). Ensure you give these areas extra attention when applying your waterproofing treatment.

Making the Right Choice for Your Goal

Your maintenance strategy should be tailored to the boots you own to ensure their longevity and performance.

- If your primary boots are full-grain leather: Focus on conditioning with waxes or creams to nourish the material while creating a robust waterproof barrier.

- If your primary boots are suede, nubuck, or fabric: Rely on specialized waterproof sprays that restore water repellency without damaging the material's texture.

- If your primary boots have a waterproof membrane (like Gore-Tex): Remember that treating the exterior is non-negotiable for maintaining the membrane's critical breathability.

Consistent and correct maintenance transforms your boots from a simple purchase into a reliable, long-term shield against the elements.

Summary Table:

| Step | Action | Key Consideration |

|---|---|---|

| 1. Clean | Remove laces, brush off debris, use a gentle cleaner. | Never apply treatment to dirty boots. |

| 2. Dry | Air dry at room temperature. | Avoid direct heat sources to prevent damage. |

| 3. Choose Treatment | Wax for smooth leather; Spray for suede/synthetics. | Using the wrong product can ruin the material. |

| 4. Apply | Apply evenly, focusing on seams. Let cure fully. | Proper application ensures a durable barrier. |

Need a Reliable Supply of Durable Winter Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, waterproof shoes and boots built to withstand the toughest conditions.

Partner with us to provide your customers with quality they can depend on.

Contact our team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety

- What maintenance tips are recommended for leather safety footwear? Extend Lifespan & Preserve Safety

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- What type of boots are suitable for challenging weather conditions in a business setting? | Durable & Professional Footwear