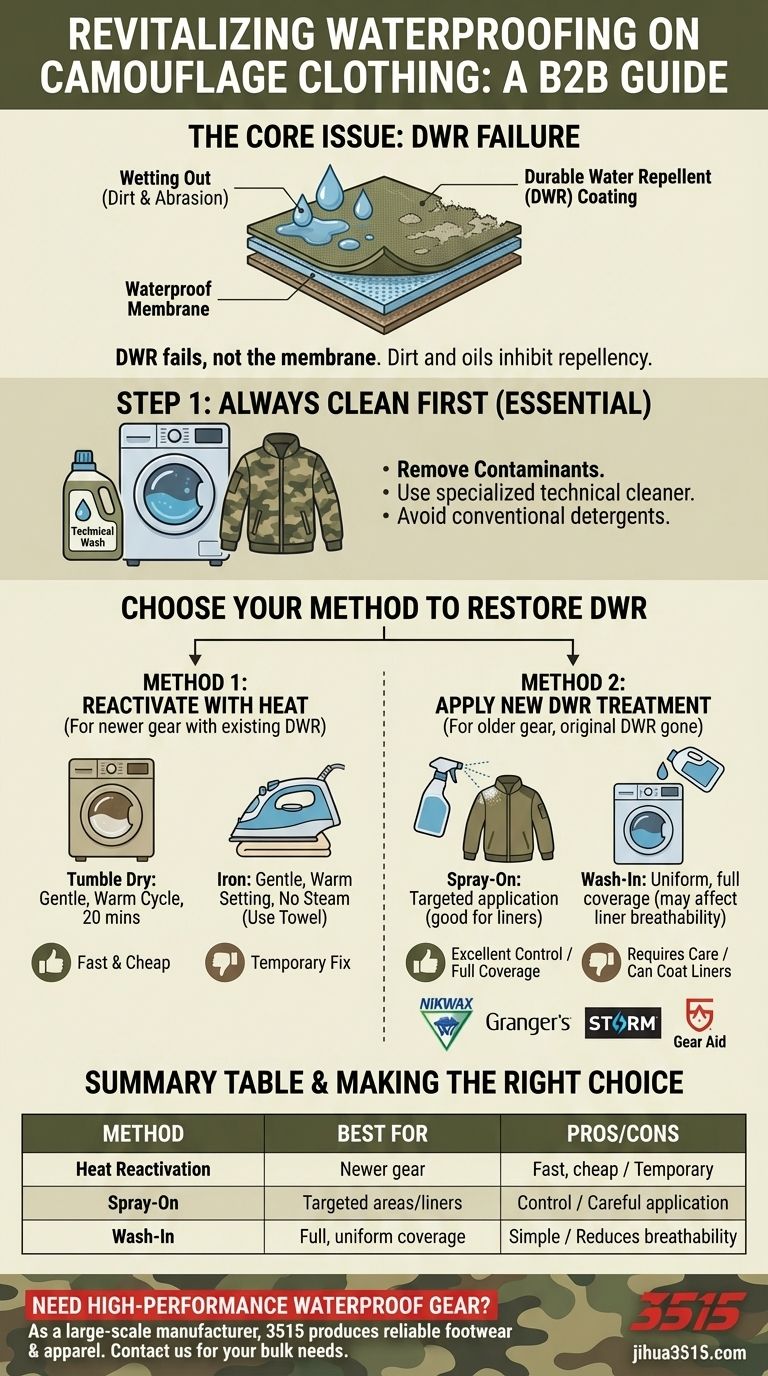

To revitalize the waterproofing on camouflage clothing, you can either reactivate the existing water-repellent coating with gentle heat or apply a new, specialized waterproofing treatment. The first step is always to clean the garment, as dirt and oils inhibit water repellency.

The core issue is almost always the failure of the garment's Durable Water Repellent (DWR) coating, not the waterproof membrane itself. Your goal is to either revive this existing coating with heat or replace it entirely with a new treatment.

Why Your Gear Stops Repelling Water

The Role of DWR

Most waterproof clothing has a DWR finish applied to the outer fabric. This is a chemical treatment that causes water to bead up and roll off, preventing the fabric from "wetting out" or becoming saturated.

The Impact of Dirt and Abrasion

Over time, dirt, body oils, and simple abrasion from use wear down the DWR coating. When this happens, water no longer beads up, and the fabric absorbs moisture, making the garment feel damp, heavy, and less breathable, even if the underlying waterproof membrane isn't leaking.

Step 1: Always Clean Your Garment First

Remove Contaminants

You cannot effectively waterproof a dirty piece of clothing. Dirt and residue clog the fabric and prevent any treatment—whether heat or a new chemical—from working properly.

Use a Technical Wash

Wash the garment according to its care label, preferably using a specialized technical cleaner designed for outdoor gear. Avoid conventional detergents, as they can leave behind residues that attract water.

Step 2: Method 1 - Reactivating DWR with Heat

If your gear is relatively new, a simple heat treatment can often revive the original DWR coating that has become dormant.

Using a Tumble Dryer

After the garment has been washed and is completely air-dried, place it in a tumble dryer. Run it on a gentle, warm cycle for 20 minutes. This heat can reactivate the DWR molecules, restoring their water-repellent properties.

Using an Iron

If the care label allows and you don't have a dryer, you can use an iron. Place a towel over the garment to protect it. Set your iron to a gentle, warm setting with no steam and carefully iron the fabric.

Step 3: Method 2 - Applying a New DWR Treatment

If heat treatment doesn't work, the original DWR is likely gone. You will need to apply a new coating using a specialized product from brands like NikWax, Granger's, STORM, or Gear Aid.

Spray-On Treatments

These are applied directly to the outside of the clean, and often still damp, garment. Sprays offer excellent control, allowing you to concentrate the treatment on high-wear areas like the shoulders and cuffs.

Wash-In Treatments

These are added to your washing machine for an easy and uniform application. The entire garment is submerged, ensuring complete and even coverage inside and out.

Understanding the Trade-offs

Heat Reactivation

This is the fastest and cheapest method. However, it only works if there is a sufficient amount of the original DWR finish remaining on the fabric. It is often a temporary fix.

Spray-On Treatments

Sprays are ideal for targeting specific areas and for garments with wicking liners, as they only treat the outer fabric. However, application requires care to ensure even coverage and avoid a patchy finish.

Wash-In Treatments

Wash-in products are incredibly simple to use and guarantee full coverage. The main drawback is that they coat the entire garment, including any internal liners, which can sometimes slightly reduce the breathability of wicking fabrics.

Making the Right Choice for Your Goal

- If your primary focus is a quick refresh for a newer garment: Clean it and use the tumble dryer or iron method to reactivate the existing DWR.

- If your primary focus is a full restoration of old, heavily used gear: Clean the garment, then apply a new spray-on or wash-in DWR treatment.

- If your primary focus is treating gear with a moisture-wicking liner: Use a spray-on treatment to avoid compromising the liner's ability to breathe and manage sweat.

Properly restoring your gear's water repellency ensures you remain dry, comfortable, and focused during any outdoor activity.

Summary Table:

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Heat Reactivation | Newer garments with existing DWR | Fast, cheap, no chemicals | Temporary fix, requires sufficient original DWR |

| Spray-On Treatment | Targeted areas, gear with liners | Excellent control, avoids coating liners | Requires careful application for even coverage |

| Wash-In Treatment | Full, uniform coverage | Simple to use, complete coverage | Can coat internal liners, may reduce breathability |

Need to source high-performance, durable waterproof clothing? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and apparel for distributors, brand owners, and bulk clients. Our production capabilities ensure reliable, long-lasting DWR coatings and waterproof membranes. Contact us today to discuss your manufacturing needs and ensure your customers stay dry and comfortable.

Visual Guide

Related Products

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- How can you manually help break in the bend areas of boots? Speed Up Comfort and Fit

- How should synthetic leather riding boots be cared for? Simple Steps for Long-Lasting Performance

- Why is a 30-second sampling duration used for footwear stability? Find the Sweet Spot for Accurate Postural Sway Data

- What is the specific value of employing computerized embroidery for SMA filaments? Engineering Active Smart Textiles

- How do half chaps enhance the functionality of paddock boots? A Guide to Better Riding Performance

- Why are sensors based on micro-inertial measurement units (IMUs) preferred for analyzing forestry working postures?

- How does a high-precision computerized balance platform evaluate the stability and Sway Velocity Index (SVI) of functional footwear? Unlock Scientific Performance Data

- Why is it important to take care of your feet? Secure Your Mobility and Overall Health