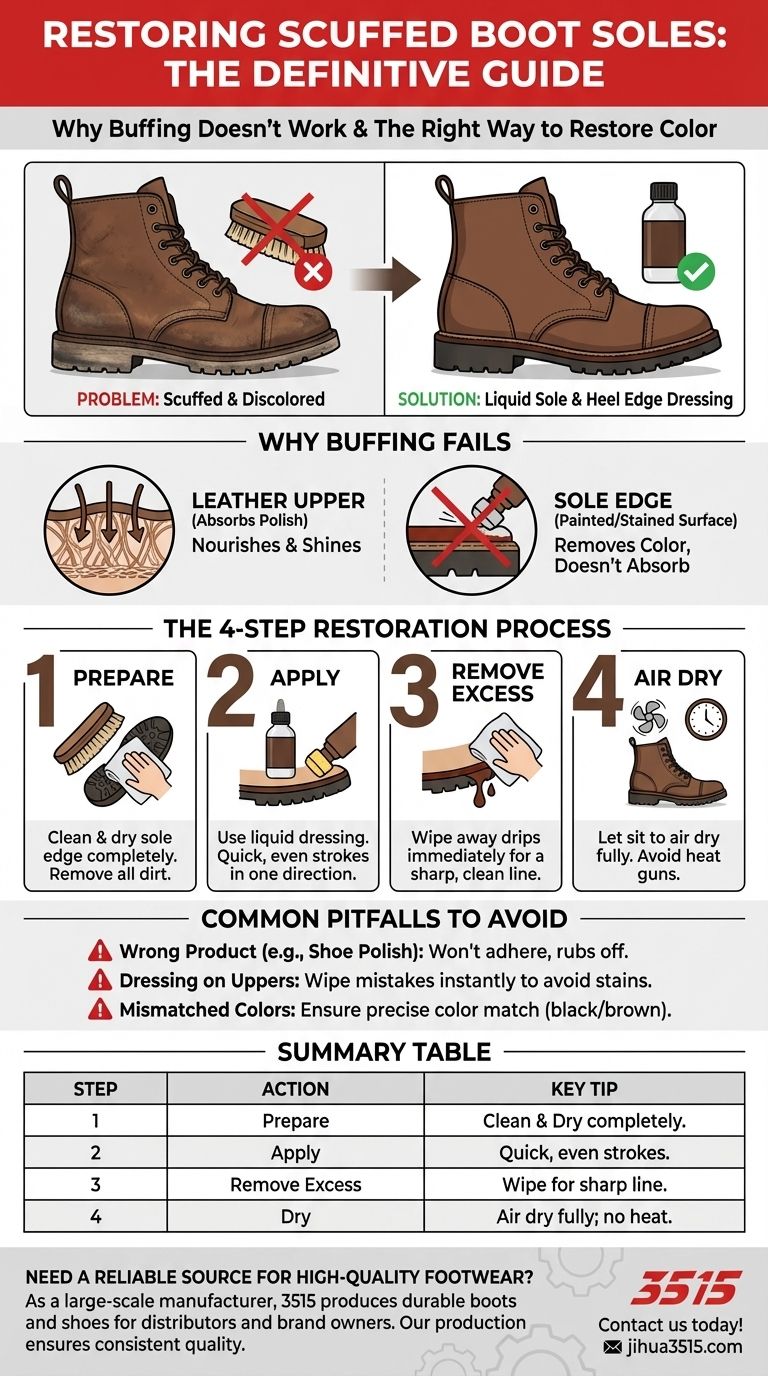

For scuffed and discolored boot soles, the solution is not to buff or polish them, but to re-stain them using a product specifically designed for the job. The most effective tool is a liquid sole and heel edge dressing, which restores the original color and finish to the border of your boots, making them look sharp and new again.

The core issue with worn boot soles is a loss of color, not a problem that can be buffed out. The correct approach is to reapply the finish using a specialized edge dressing, which acts like a stain or paint for the sole's edge.

Why Buffing Doesn't Work on Boot Soles

A Different Material, A Different Treatment

The leather on the upper part of your boot is treated to absorb polish and shine when buffed. This process nourishes the leather and creates a lustrous finish.

A Painted or Stained Surface

In contrast, the edges of most leather, rubber, or composite soles are finished with a colored coating at the factory. When this edge gets scuffed, you are scraping away the paint or stain itself.

The Wrong Tool for the Job

Attempting to buff this surface will, at best, do nothing. At worst, it can smear dirt or damage the surrounding material without restoring any of the lost color.

The Definitive Guide to Restoring Your Soles

Step 1: Prepare the Surface

Before applying anything, you must clean the sole edge. Use a stiff brush to remove any caked-on dirt, followed by a damp cloth to wipe away fine dust and grime.

Allow the area to dry completely. Applying dressing to a wet or dirty surface will result in an uneven, splotchy finish.

Step 2: Apply the Edge Dressing

Most sole edge dressings come in a bottle with a built-in applicator, similar to a bottle of shoe polish. Shake the bottle well before use.

Apply the dressing with quick, even strokes, moving in one direction along the edge of the sole. Do not dab or over-saturate the area. The goal is a thin, consistent coat.

Step 3: Remove the Excess

Immediately after applying the dressing, take a clean cloth and lightly wipe away any excess that may have dripped or beaded up.

This step is crucial for preventing drips and creating a clean, sharp line between the sole and the upper part of the boot.

Step 4: Allow to Air Dry

Let the boots sit and air dry completely. Avoid using heat guns or hair dryers, as this can cause the finish to crack or bubble.

Ensure the dressing is fully cured before wearing the boots to prevent smudging the fresh finish.

Common Pitfalls to Avoid

Using the Wrong Product

Do not use standard leather shoe polish on your sole edges. It is not formulated to adhere to these surfaces and will simply rub off without restoring the color. Stick to products explicitly labeled as "sole edge dressing."

Getting Dressing on the Uppers

Be careful not to get the dressing on the upper leather of your boots, especially if the colors are different. If you make a mistake, wipe it off immediately with a damp cloth before it has a chance to set.

Mismatched Colors

Sole edge dressing is most commonly available in black and brown. Ensure the color you choose is a precise match for your boot's original sole color to maintain a professional appearance.

Making the Right Choice for Your Goal

- If your primary focus is restoring color to scuffed sole edges: Use a liquid sole and heel edge dressing that matches your boot's color for a factory-fresh finish.

- If your primary focus is fixing deep gouges in the sole material: Edge dressing is cosmetic; for significant structural damage, you should consult a professional cobbler.

- If your primary focus is shining the leather upper of the boot: Use a quality boot polish or cream and a horsehair brush or buffer, as this requires a completely different product and technique.

Restoring your boot's foundation is a simple process that has a major impact on its overall appearance.

Summary Table:

| Step | Action | Key Tip |

|---|---|---|

| 1 | Prepare | Clean & dry the sole edge completely. |

| 2 | Apply | Use liquid sole dressing with quick, even strokes. |

| 3 | Remove Excess | Wipe away drips immediately for a sharp line. |

| 4 | Dry | Let air dry fully; avoid heat to prevent cracking. |

| Avoid | Using shoe polish | It will not adhere and will rub off. |

| Avoid | Getting dressing on uppers | Wipe off mistakes instantly. |

Need a reliable source for high-quality footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of durable boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure consistent quality and finish, right down to the sole. Let us be your trusted manufacturing partner. Contact us today to discuss your needs!

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Wholesale Comfort Dress Shoes with Dial Closure for Custom Manufacturing

People Also Ask

- How does a multi-camera motion capture system validate gait and posture? The Science of Foot Strike Correlations

- What is the 60-Day Comfort Guarantee? Get a Risk-Free Boot Purchase

- What is the benefit of using neoprene booties for winter cycling? Stay Warm & Dry on Cold Rides

- What is the primary function of functional footwear? Relieve Joint Pressure with Advanced Engineering

- What are the traditional and contemporary options for dressage boots? Choose the Perfect Boot for Your Riding Style

- What are the benefits of wearing lightweight shoes? Reduce Fatigue & Boost Comfort for Work & Play

- What hazards do damaged laces or bindings pose? Avoid Costly Workplace Injuries

- What role do CAD and CAM systems play in digital footwear and garment manufacturing? Enhancing Precision & Efficiency