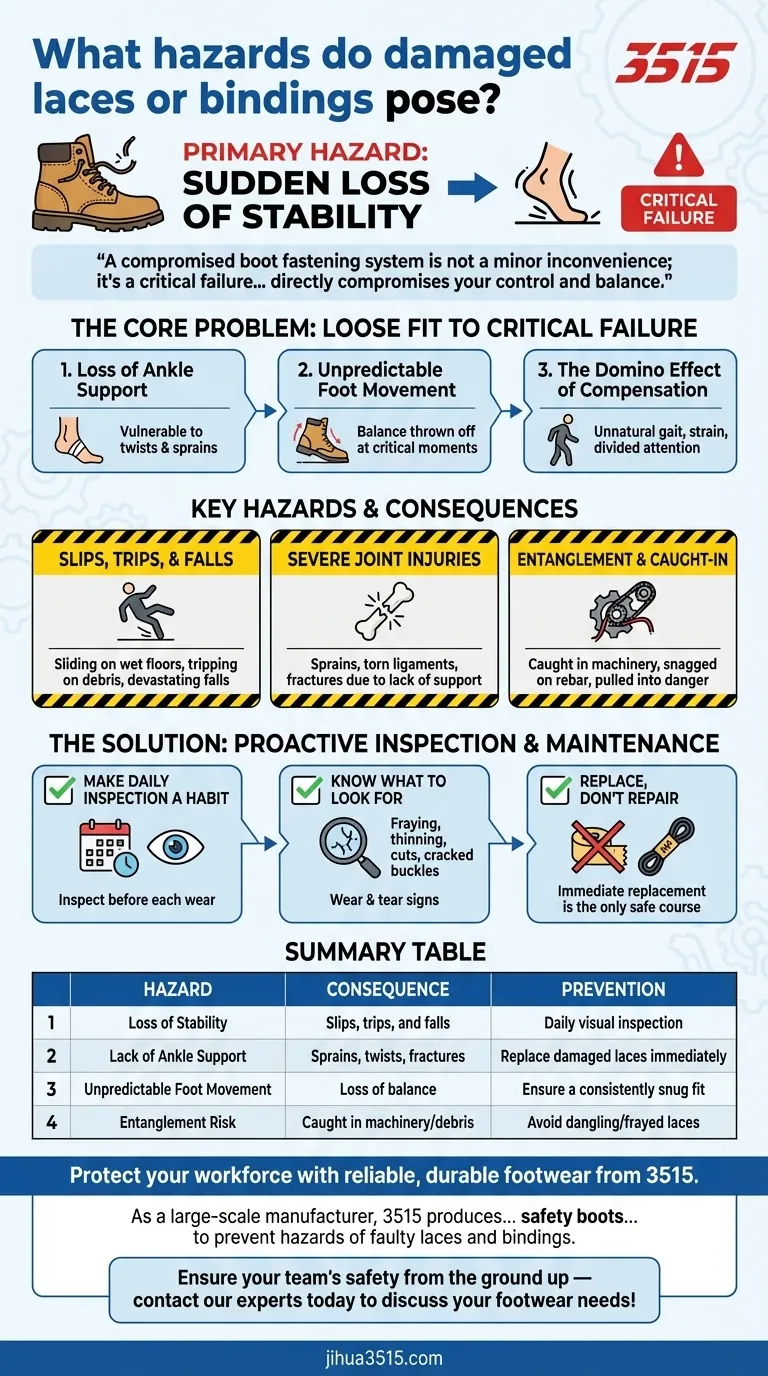

The primary hazard of damaged laces or bindings is a sudden loss of stability. When a boot is no longer securely fastened to your foot, it creates an unpredictable and unstable base, dramatically increasing the risk of slips, trips, and falls that can lead to serious injury.

A compromised boot fastening system is not a minor inconvenience; it's a critical failure of your personal protective equipment that directly compromises your control and balance, especially in hazardous environments.

The Core Problem: From Loose Fit to Critical Failure

A securely fastened boot is the foundation of your stability. When that connection is broken due to damaged laces or bindings, it sets off a dangerous chain reaction that compromises your safety.

The Loss of Ankle Support

Properly tightened boots provide essential support to your ankles. This support is critical for preventing twists and sprains, particularly when walking on uneven ground or carrying heavy loads. A damaged lace or binding eliminates this function entirely, leaving your ankle vulnerable to injury.

Unpredictable Foot Movement

When a boot is loose, your foot can shift and slide inside it unexpectedly. This slight movement is all it takes to throw off your balance at a critical moment, such as when stepping onto a ladder, navigating a slippery surface, or climbing an incline.

The Domino Effect of Compensation

Your body will instinctively try to compensate for the instability of a loose boot. This can lead to an unnatural gait, placing additional strain on your knees, hips, and back. More importantly, it divides your attention, forcing you to focus on simply walking instead of on other potential hazards in your environment.

Key Hazards and Their Consequences

The loss of stability caused by faulty laces and bindings manifests in several specific, high-risk scenarios. Understanding these outcomes makes the danger clear.

Slips, Trips, and Falls

This is the most direct and common consequence. A foot sliding inside a boot can cause a slip on a wet floor. A dangling broken lace can easily catch on equipment, debris, or scaffolding, resulting in a trip or a devastating fall.

Severe Joint Injuries

Without the necessary ankle support, a simple misstep can turn into a severe sprain, a torn ligament, or even a bone fracture. The boot is designed to protect the joint, but it cannot do its job if it is not securely attached to your foot.

Entanglement and Caught-in Hazards

In industrial or outdoor environments, a broken, dangling lace poses a significant entanglement risk. It can get caught in rotating machinery, snagged on rebar, or tangled in brush, pulling you off balance or directly into a hazardous situation.

The Solution: Proactive Inspection and Maintenance

The good news is that these hazards are almost entirely preventable through simple, consistent diligence. The responsibility lies in treating your footwear as a critical piece of safety equipment.

Make Daily Inspection a Habit

Before putting on your boots each day, take a few seconds to inspect the laces or bindings. This is not a time-consuming task, but it is a vital one. It should be as automatic as checking the mirrors in a car before driving.

Know What to Look For

Look for clear signs of wear and tear. For laces, this includes fraying, thinning, cuts, or abrasion. For bindings or buckles, check for cracks, stress marks, or bent components that could fail under pressure.

Replace, Don't Repair

When you identify damage, the only safe course of action is immediate replacement. Attempting a temporary fix or "just getting through the day" is an unnecessary gamble with your safety. A new pair of laces is a minor expense that eliminates a major risk.

Making the Right Choice for Your Safety

Your approach to footwear safety should be dictated by the risks of your specific environment.

- If your primary focus is working at height or climbing: Your greatest risk is a catastrophic fall, making a pre-wear lace and binding inspection a non-negotiable part of your routine.

- If your primary focus is navigating uneven or slippery ground: Your main concern is joint injury and loss of traction, so ensuring a consistently snug and secure fit is essential for stability.

- If your primary focus is working around machinery: Your most acute hazard is entanglement, meaning any damaged or dangling lace must be replaced immediately to prevent it from being caught.

Ultimately, the integrity of your boot's fastening system is a direct reflection of your commitment to personal safety.

Summary Table:

| Hazard | Consequence | Prevention |

|---|---|---|

| Loss of Stability | Slips, trips, and falls | Daily visual inspection |

| Lack of Ankle Support | Sprains, twists, fractures | Replace damaged laces immediately |

| Unpredictable Foot Movement | Loss of balance on ladders/slopes | Ensure a consistently snug fit |

| Entanglement Risk | Caught in machinery or debris | Avoid dangling or frayed laces |

Protect your workforce with reliable, durable footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and work footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the highest standards for durability and safety, helping you prevent the hazards of faulty laces and bindings.

Ensure your team's safety from the ground up — contact our experts today to discuss your footwear needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.