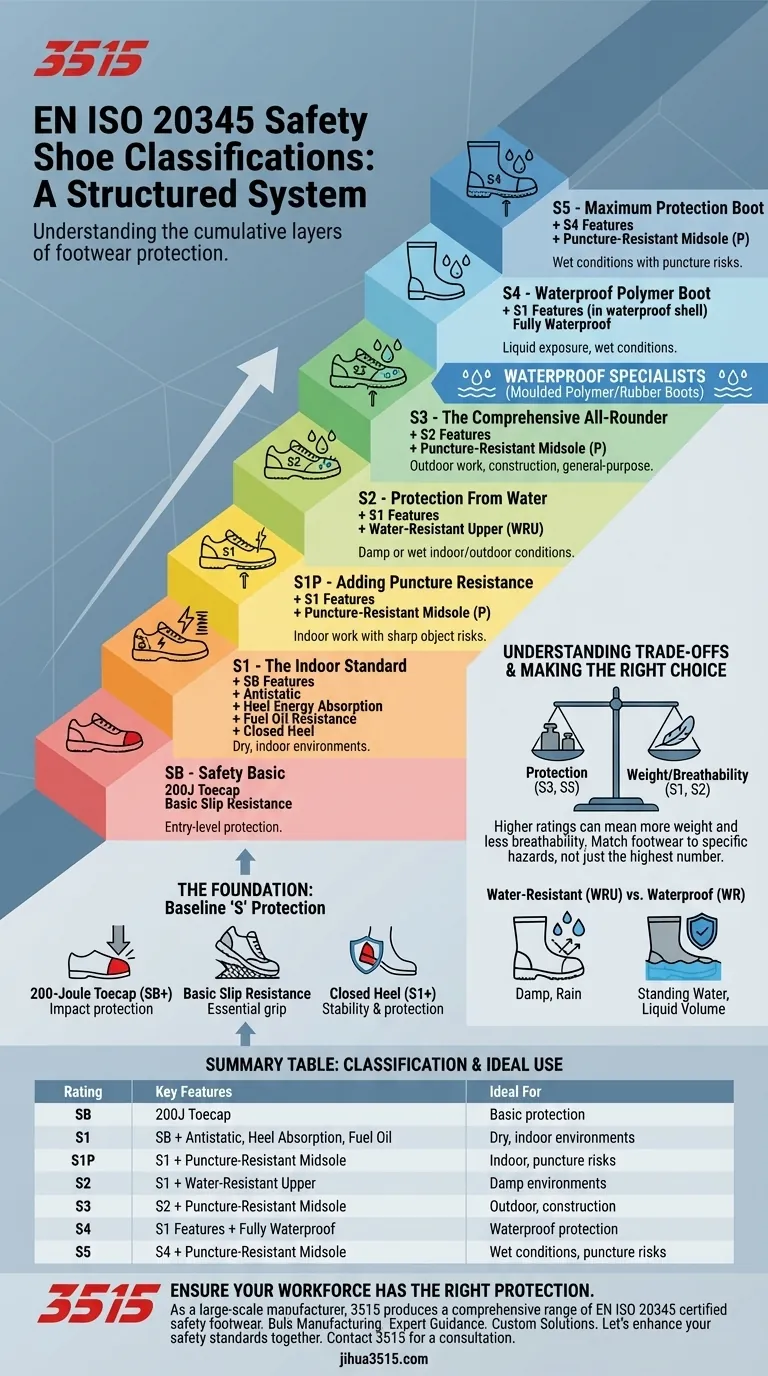

To understand safety shoe classifications, you must see them not as a random list, but as a structured, cumulative system. Under the EN ISO 20345 standard, footwear is categorized with an 'S' rating, starting with the basic SB and progressing through S1, S1P, S2, S3, S4, and S5. Each successive level incorporates the protective features of the level below it while adding new, specific safeguards for increasingly hazardous environments.

The EN ISO 20345 standard isn't just a list of shoe types; it's a logical framework that builds layers of protection. Your goal is to match your work environment's specific hazards—like water, sharp objects, or static discharge—to the corresponding safety rating, ensuring you have precisely the protection you need.

The Foundation: What 'S' Fundamentally Means

Before diving into the specific numbers, it's crucial to understand the baseline protection guaranteed by any shoe marked with an 'S' under EN ISO 20345. These are the non-negotiable minimums.

The 200-Joule Toecap

Every classified safety shoe, from SB upwards, must have a protective toecap. This component is tested to withstand an impact of 200 joules, which is the energy equivalent of a 20kg (44 lb) weight dropped from a height of approximately one meter.

Basic Slip Resistance

The standard also mandates that the outsole provides a fundamental level of slip resistance. While higher ratings for slip resistance exist, a basic grip on common surfaces is a prerequisite.

A Closed Heel Area

For any rating of S1 and above, the shoe must feature a fully enclosed heel area. This provides better stability and protects the back of the foot.

Decoding the Primary 'S' Classifications

The classification system is progressive. Think of each number as adding a new layer of defense tailored for a specific type of work environment.

SB - Safety Basic

This is the entry-level rating. An SB-rated shoe has the mandatory 200-joule toecap but may be open at the back, like a clog. It meets the absolute minimum requirement to be called safety footwear.

S1 - The Indoor Standard

The S1 rating is designed for dry, indoor work environments where impact risk to the toes is the primary concern. It includes all SB features, plus:

- Antistatic properties (A)

- Energy absorption in the heel (E)

- Resistance to fuel oil (FO)

- A fully enclosed heel

S1P - Adding Puncture Resistance

The S1P rating is an extremely common and crucial variant. It includes every feature of an S1 shoe but adds a puncture-resistant midsole (P). This protects the foot from nails, screws, and other sharp objects penetrating from below.

S2 - Protection From Water

An S2 shoe builds upon the S1 standard. The key addition is a water-resistant upper (WRU), which prevents water penetration and absorption for a limited time. It's suited for damp environments but is not fully waterproof.

S3 - The Comprehensive All-Rounder

S3 is often considered the most complete rating for general-purpose safety footwear. It combines the features of an S2 (water-resistant upper) and an S1P (puncture-resistant midsole), making it ideal for most outdoor and construction work.

S4 & S5 - The Waterproof Specialists

These ratings apply to footwear made from moulded polymer or rubber, such as Wellington boots, which are inherently waterproof.

- S4: Includes all S1 features but in a fully waterproof and leak-proof shell.

- S5: This is the highest level. It is an S4 boot with the critical addition of a puncture-resistant midsole (P).

Understanding the Trade-offs

Choosing the right safety shoe isn't about picking the highest number. It's about finding the right balance for your specific role, as higher protection often involves compromises.

More Protection Isn't Always Better

Higher-rated shoes, particularly S3 and S5, are often heavier and less breathable than S1 or S2 models. For a worker in a dry, indoor warehouse, an S3 shoe can cause unnecessary fatigue and discomfort compared to a lighter, more breathable S1P.

'Water-Resistant' vs. 'Waterproof'

There is a critical difference between the S2/S3 and S4/S5 ratings. The S2/S3 uppers are water-resistant (WRU), meaning they can handle rain and damp conditions. S4/S5 boots are fully waterproof (WR), designed for standing in water or dealing with significant liquid exposure.

The Myth of the 'Do-It-All' Shoe

No single shoe is perfect for every job. An S5 boot offers maximum protection from punctures and liquids but is ill-suited for a job requiring agility and hours of walking on a factory floor. The goal is to match the hazard profile, not to over-spec your footwear.

Making the Right Choice for Your Environment

To apply this knowledge, analyze your daily tasks and workplace hazards. Your selection should be a direct response to the risks you face.

- If you work primarily indoors in a dry environment: An S1 shoe is sufficient, but an S1P is highly recommended to protect against stray sharp objects.

- If your work involves a risk of ground punctures (construction, waste management): Your minimum starting point must include the 'P' designation, making S1P, S3, or S5 your only viable options.

- If you work outdoors or in frequently damp conditions: An S3 shoe provides the necessary balance of water resistance and all-around protection.

- If your work requires you to stand in water or be exposed to large volumes of liquids: A fully waterproof S4 or, more likely, an S5 boot is non-negotiable.

By understanding this system, you can select footwear not just for compliance, but for genuine, targeted safety.

Summary Table:

| Classification | Key Protective Features | Ideal For |

|---|---|---|

| SB | 200-joule toecap | Basic protection, entry-level use |

| S1 | SB + Antistatic, Heel Energy Absorption, Fuel Oil Resistance | Dry, indoor environments |

| S1P | S1 + Puncture-resistant midsole | Indoor work with puncture risks (nails, sharp objects) |

| S2 | S1 + Water-resistant upper | Damp or wet indoor environments |

| S3 | S2 + Puncture-resistant midsole | Outdoor work, construction, general-purpose use |

| S4 | S1 features in a fully waterproof, leak-proof shell | Waterproof protection (e.g., Wellington boots) |

| S5 | S4 + Puncture-resistant midsole | Maximum protection in wet conditions with puncture risks |

Ensure Your Workforce Has the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from basic SB models to specialized S5 waterproof boots, ensuring you get precisely the protection your team needs.

We provide:

- Expert Guidance: Match the right safety rating (SB to S5) to your specific work hazards.

- Bulk Manufacturing: High-volume production of durable, compliant safety footwear.

- Custom Solutions: Tailored footwear for your brand or unique operational requirements.

Let's enhance your safety standards together.

Contact 3515 today for a consultation to discuss your safety footwear needs and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time