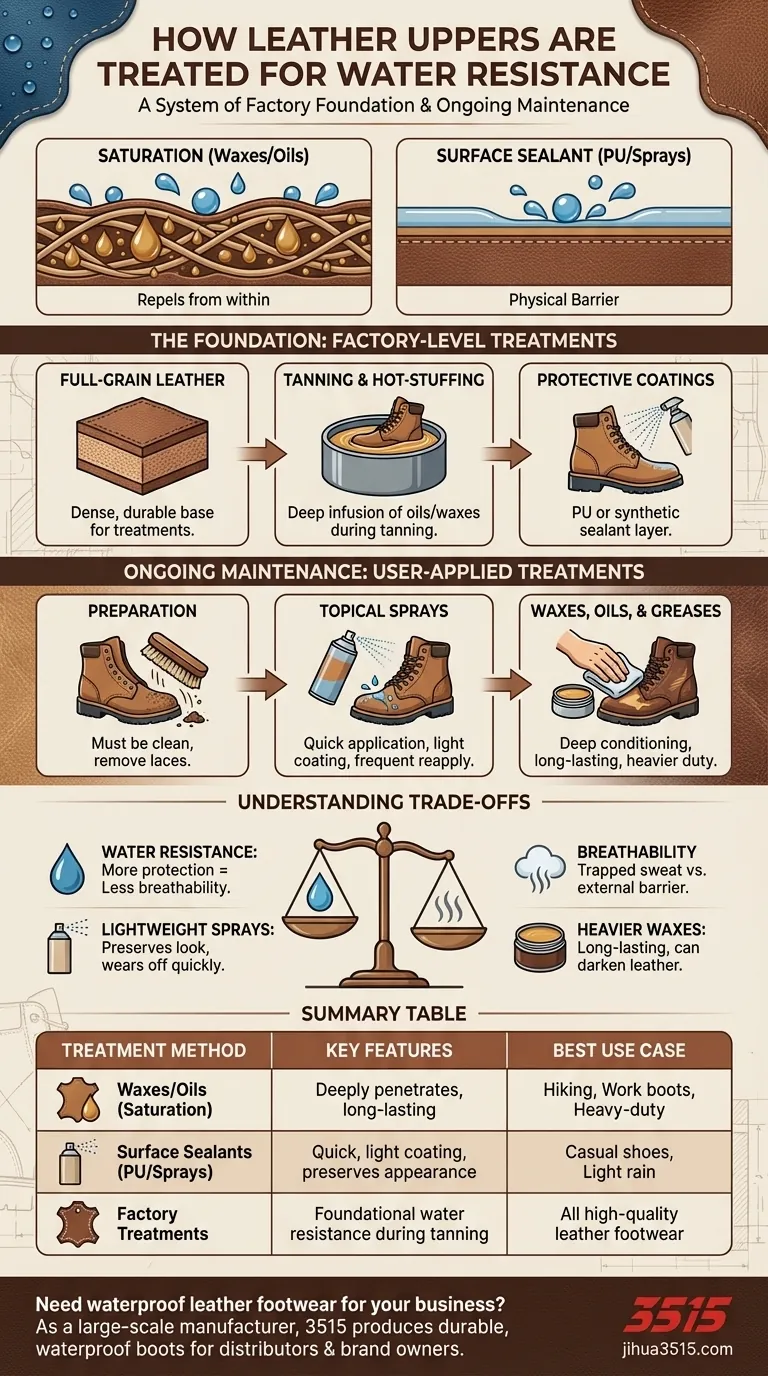

At its core, leather is treated for water resistance through two primary methods: saturation with waxes or oils that repel water, or the application of a surface-level sealant like a polyurethane finish or a topical spray. These treatments are applied both during the manufacturing process and as part of ongoing maintenance by the owner.

The key to understanding waterproof leather is realizing it's rarely about a single treatment. Instead, it's a system that combines the natural density of high-quality leather with specialized conditioning agents that must be reapplied over time to maintain effectiveness.

The Foundation: Factory-Level Treatments

Before a boot ever reaches a store, the leather undergoes initial treatments to prepare it for the elements. This foundational layer is crucial for long-term performance.

The Role of Full-Grain Leather

High-quality waterproof footwear almost always starts with full-grain leather. This is the most durable and naturally water-resistant part of the hide, as its dense fiber structure provides an excellent base for waterproofing treatments.

Tanning and Finishing Agents

During the modern tanning process, tanneries can infuse the leather with specialized oils and waxes. This "hot-stuffing" process saturates the hide, ensuring the water-repellent agents penetrate deep into the fibers rather than just sitting on the surface.

Protective Surface Coatings

Some leathers are finished with a very thin polyurethane (PU) coating or a similar synthetic sealant. This creates a consistent physical barrier that blocks water from ever reaching the leather fibers, though it can impact the material's natural breathability.

Ongoing Maintenance: User-Applied Treatments

Factory treatments degrade over time with use, exposure, and flexing. Regular care is essential to restore and maintain the leather's water-repellent properties.

The Importance of Preparation

Before applying any treatment, the leather must be clean. Always remove laces and brush off any loose dirt or mud. Applying products to a dirty surface traps grit and prevents the treatment from properly absorbing.

Topical Waterproofing Sprays

For a quick and easy layer of protection, aerosol or pump sprays are highly effective. These products apply a light coating that causes water to bead up and roll off the surface. They are excellent for casual use but typically require frequent reapplication.

Waxes, Oils, and Greases

For maximum durability and deep conditioning, waxes, oils, and greases are the best option. These products are worked into the leather, saturating the fibers to repel water from within. This method is common for heavy-duty hiking and work boots.

Understanding the Trade-offs

No single waterproofing method is perfect. The most significant trade-off is between water resistance and breathability, which is leather's natural ability to allow moisture vapor (sweat) to escape.

The Breathability Challenge

Heavy coatings like thick wax or polyurethane create a highly effective barrier against external water. However, this same barrier can also trap sweat inside the boot, leading to discomfort.

The Durability Factor

Lightweight sprays are excellent for preserving the leather's original look and feel, but they wear off quickly. Heavier waxes provide long-lasting protection but can darken the leather and require more effort to apply correctly.

Making the Right Choice for Your Goal

The best approach depends entirely on your footwear and how you use it.

- If your primary focus is protecting casual shoes from light rain: A simple waterproofing spray is fast, easy, and preserves the shoe's original appearance.

- If your primary focus is maximum durability for hiking or work boots: A high-quality wax or oil-based treatment will provide the robust, long-lasting protection you need.

- If your primary focus is restoring an older, dried-out pair of boots: Begin with a leather conditioner to restore oils before applying a wax-based waterproofing product.

Ultimately, understanding how leather is waterproofed empowers you to provide the right care, ensuring your footwear performs well and lasts for years.

Summary Table:

| Treatment Method | Key Features | Best Use Case |

|---|---|---|

| Waxes/Oils (Saturation) | Deeply penetrates leather fibers, long-lasting protection | Hiking boots, work boots, heavy-duty footwear |

| Surface Sealants (PU/Sprays) | Quick application, light coating, preserves appearance | Casual shoes, light rain protection |

| Factory Treatments | Applied during tanning, provides foundational water resistance | All high-quality leather footwear |

Need waterproof leather footwear for your business? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, waterproof boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure top-tier leather treatment and lasting performance. Contact us today to discuss your footwear needs!

Visual Guide

Related Products

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Dial Closure Leather Business Casual Shoes for Wholesale & Private Label

- Wholesale Breathable Perforated Leather Derby Dress Shoes for Custom Brands

- Wholesale Breathable Perforated Leather Derby Shoes with Modern Comfort Sole

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

People Also Ask

- What are sport and racing motorcycle boots and their key attributes? Essential Protection for High-Speed Riding

- How should hunting boots fit properly? A Guide to Perfect Fit for Every Hunt

- What aesthetic advantages do high-quality riding boots offer? Achieve a Polished, Professional Equestrian Look

- What makes Old England leather suitable for outdoor footwear? Discover Unmatched Durability & Comfort

- What factors should be considered when choosing snake boots? Balance Protection, Comfort & Mobility

- What are the four key factors to consider when choosing hunting boots? A Guide to Perfect Fit & Performance

- What types of insulation are commonly used in winter boots? A Guide to Thinsulate, Shearling & More

- What are the key factors affected by the materials used in motorcycle boots? Choose the Right Protection for Your Ride