Boots designed to meet the ASTM standard for electrical hazard (EH) protection are constructed entirely from non-conductive materials. The key is to build a shoe that completely insulates the wearer from the ground. This is achieved by using materials like rubber and leather for the outsoles, heels, and internal shanks, and by strictly avoiding any metal or other conductive components that could create a path for electricity.

The fundamental purpose of an EH-rated boot is not just to be non-conductive, but to act as a critical insulator. It is designed to stop the wearer's body from completing a dangerous electrical circuit in the event of accidental contact with a live wire.

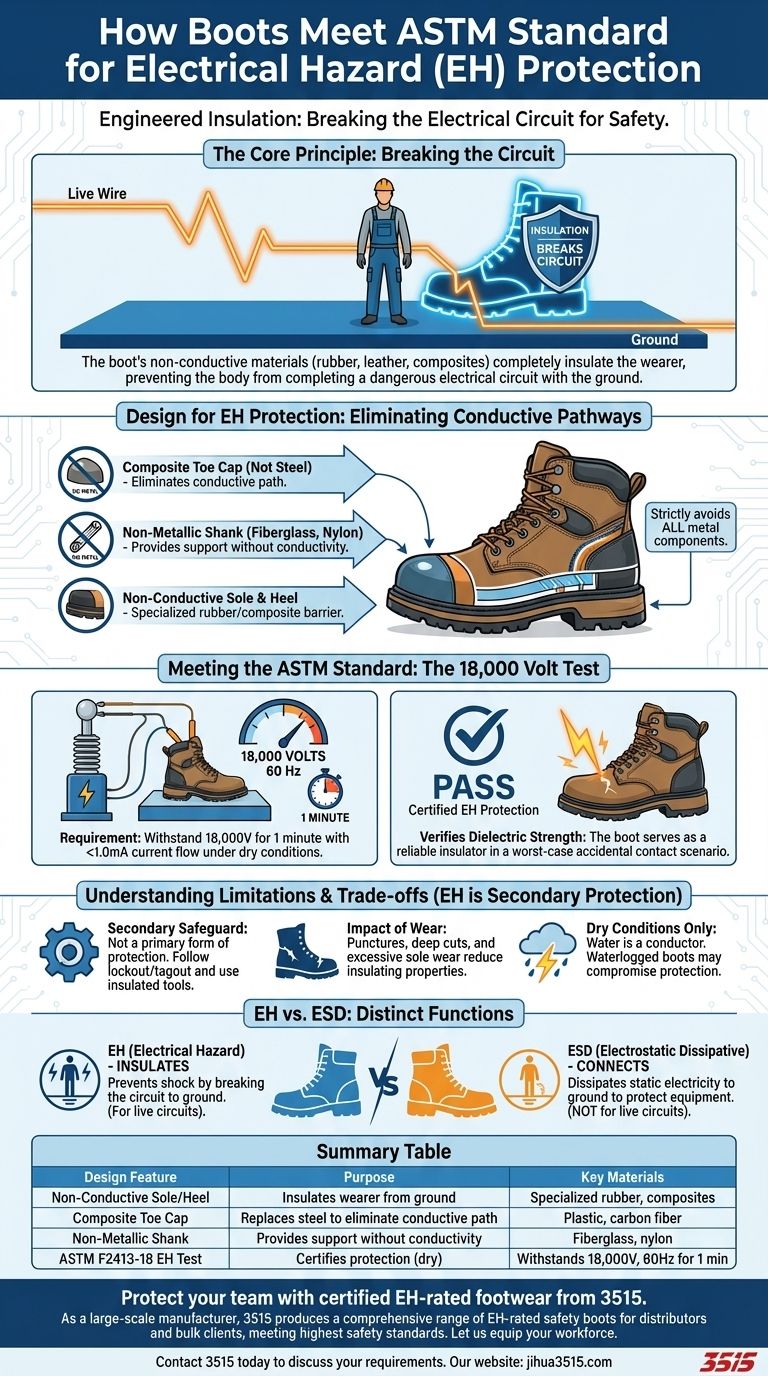

The Core Principle: Breaking the Electrical Circuit

To understand EH boot design, you must first understand how a dangerous electrical shock occurs. For electricity to flow through your body, you must become part of a complete circuit between an energized source and the ground.

How Insulation Provides Protection

The primary function of an EH-rated boot is to act as an insulator. The specialized rubber or composite materials used in the sole and heel create a substantial barrier that resists the flow of electricity.

This insulation effectively breaks the circuit. If you accidentally step on or come into contact with a live electrical source, the boot prevents the current from passing through you to the ground, mitigating the risk of serious injury or electrocution.

Eliminating Conductive Pathways

A critical design requirement is the complete absence of conductive materials in the boot's construction. This is why true EH-rated safety boots will feature a composite toe cap instead of a steel one.

Likewise, the boot's shank—a supportive piece in the sole—must be made of a non-conductive material like fiberglass or nylon, not steel. Every component is chosen to ensure no pathway for electricity exists.

Meeting the ASTM Standard: The 18,000 Volt Test

For a boot to carry the official "EH" rating, it must pass a rigorous laboratory test defined by the ASTM (American Society for Testing and Materials).

The Specific Performance Requirement

The ASTM standard mandates that the footwear must withstand the application of 18,000 volts at 60 hertz for one full minute with no current flow or leakage in excess of 1.0 milliampere under dry conditions.

What This Test Verifies

This test simulates a worst-case scenario of accidental contact with a high-voltage source. It proves the boot’s dielectric strength—its ability to serve as a reliable insulator when it matters most. Passing this test is the definitive mark of a boot's electrical hazard protection capability.

Understanding the Limitations and Trade-offs

While essential, it's crucial to recognize that EH boots are a secondary line of defense and have specific limitations.

EH is a Secondary Protection

EH-rated footwear is not a primary form of protection. The first and most important safety measures are always de-energizing circuits, following proper lockout/tagout procedures, and using appropriate insulated tools and equipment.

The Impact of Wear and Environment

The insulating properties of EH boots can be compromised. Deep cuts, punctures, or excessive wear on the sole can reduce its protective capabilities.

Furthermore, the ASTM test is performed under dry conditions. Water is an excellent conductor of electricity, and a waterlogged boot may not provide the intended level of protection.

Do Not Confuse EH with ESD

It is critical to distinguish between Electrical Hazard (EH) and Electrostatic Dissipative (ESD) footwear. They serve opposite functions. EH boots insulate you from the ground to prevent shock. ESD boots connect you to the ground to safely dissipate static electricity and protect sensitive electronic equipment.

Making the Right Choice for Your Goal

Selecting the correct footwear depends entirely on the specific hazards of your environment.

- If your primary focus is protection from accidental contact with live electrical circuits: Ensure your boots are explicitly marked with the EH rating and regularly inspect them for damage, punctures, or excessive wear.

- If your primary focus is managing a worksite safety program: Mandate certified EH footwear as a secondary safeguard for anyone working near potential electrical hazards and integrate boot inspections into your safety protocols.

- If your primary focus is preventing static discharge in a sensitive environment: You must use footwear specifically rated for Electrostatic Dissipation (ESD), as EH boots would be counterproductive and dangerous.

Understanding that your EH-rated boots are a specialized tool for insulation is the key to using them safely and effectively.

Summary Table:

| Design Feature | Purpose | Key Materials |

|---|---|---|

| Non-Conductive Sole/Heel | Insulates wearer from the ground | Specialized rubber, composites |

| Composite Toe Cap | Replaces steel to eliminate a conductive path | Plastic, carbon fiber |

| Non-Metallic Shank | Provides arch support without conductivity | Fiberglass, nylon |

| ASTM F2413-18 EH Test | Certifies protection under dry conditions | Withstands 18,000V, 60Hz for 1 minute |

Protect your team with certified EH-rated footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of EH-rated footwear, designed and tested to meet the highest safety standards.

We ensure every pair provides the critical insulation needed to mitigate electrical hazards. Let us help you equip your workforce with reliable protection.

Contact 3515 today to discuss your EH boot requirements and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why are safety boots designated as a core detection target in PPE monitoring? Enhance Industrial Safety Compliance

- How long do work boots typically last? Maximize Lifespan & Safety

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety

- What types of heel designs are found in western work boots? Choose the Right Heel for Your Job

- In what environments can work boots be worn? From Heavy Industry to Casual Style

- How should suede and nubuck leather work boots be cleaned? A Dry-Cleaning Guide to Preserve the Nap

- How do composite toe boots handle extreme temperatures? Superior Thermal Insulation for Comfort