No, work boot manufacturers do not use the same construction methods. They employ several distinct techniques to attach the boot's upper to its sole, and this single choice is one of the most critical factors in determining a boot's durability, flexibility, water resistance, and repairability. The most common methods include Goodyear welt, cement, stitch-down, and injection-molded construction.

The way a boot is constructed is the foundation of its performance. Understanding the difference between a welted, cemented, or injection-molded boot is the key to choosing footwear that truly matches the demands of your job and your expectations for longevity.

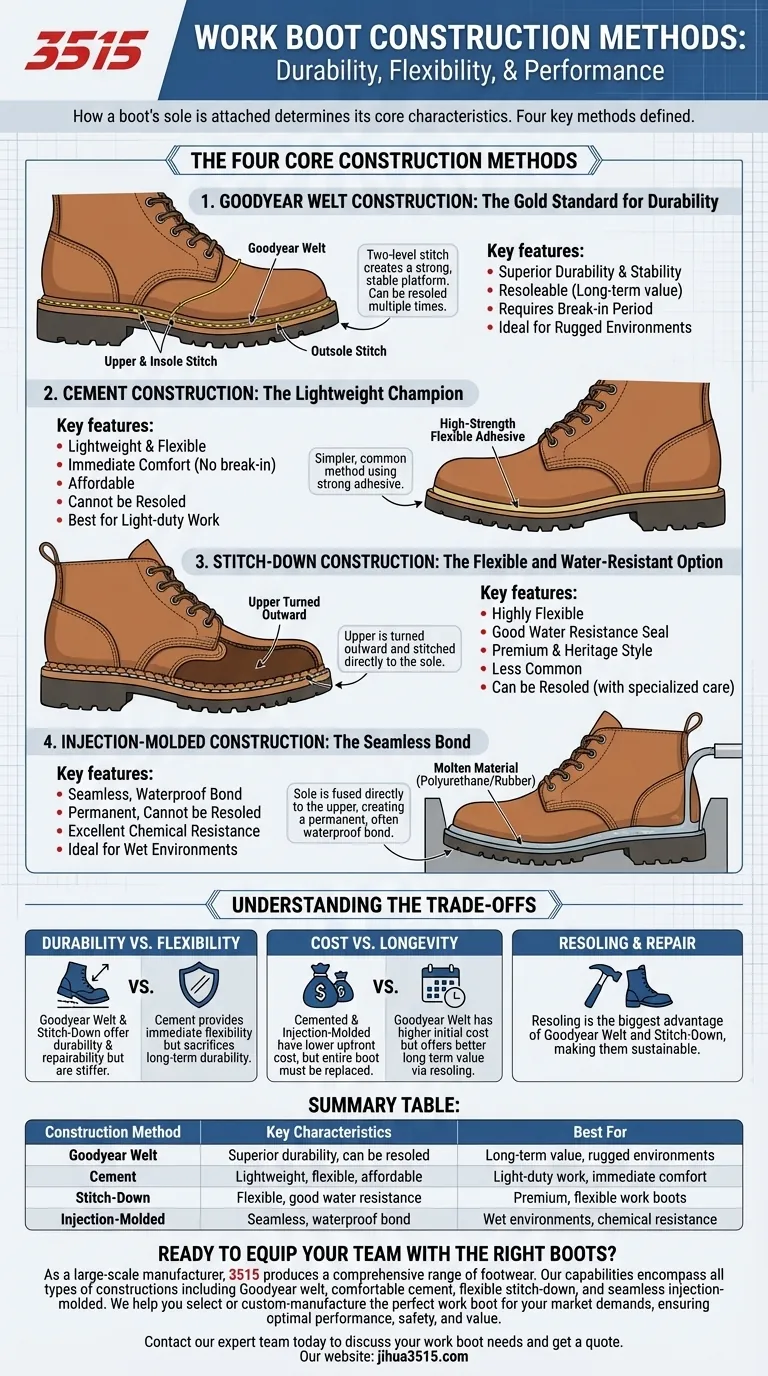

The Four Core Construction Methods

How a boot's sole is attached to its upper dictates its core characteristics. Each method serves a different purpose, balancing durability, comfort, and cost.

Goodyear Welt Construction: The Gold Standard for Durability

A Goodyear welt is a strip of leather, rubber, or plastic that is stitched to the boot's upper and the insole. The outsole is then separately stitched to this welt.

This two-level stitch creates an incredibly strong and stable platform. More importantly, it allows the boot to be resoled multiple times without damaging the upper, dramatically extending its lifespan.

Cement Construction: The Lightweight Champion

Cement construction is a simpler and more common method where the outsole is attached directly to the upper using a high-strength, flexible adhesive.

This process results in a lighter and more flexible boot right out of the box. It is also a less expensive manufacturing process, making these boots more affordable.

Stitch-Down Construction: The Flexible and Water-Resistant Option

In stitch-down construction, the leather of the upper is turned outward at the bottom and stitched directly to the midsole or outsole.

This method creates a highly flexible boot and a secure seal around the bottom, which can improve water resistance. It is a hallmark of certain high-end and heritage-style work boots.

Injection-Molded Construction: The Seamless Bond

With injection-molded or direct-attach construction, the upper is placed into a mold, and molten material (like polyurethane or rubber) is injected to form the outsole.

This process fuses the sole directly to the upper, creating a permanent and often waterproof bond. There are no stitches or adhesives that can fail in wet conditions.

Understanding the Trade-offs

Choosing the right construction method involves balancing competing priorities. No single method is universally superior; the best choice depends entirely on your needs.

Durability vs. Flexibility

Goodyear welt construction offers unparalleled durability and repairability, but this often comes with a stiffer feel that requires a break-in period.

Conversely, cement construction provides immediate flexibility and comfort but sacrifices long-term durability, as the bond can weaken over time and the boot cannot be resoled.

Cost vs. Longevity

Cemented and injection-molded boots have a lower upfront cost due to simpler manufacturing. However, once the sole wears out, the entire boot must be replaced.

Goodyear welted boots are more expensive initially but represent a better long-term value if you plan to resole and maintain them, as the uppers often outlast multiple soles.

Resoling and Repair

The ability to resole a boot is the single biggest advantage of Goodyear welt and, to a lesser extent, stitch-down construction. This makes them a more sustainable and potentially cost-effective choice over many years.

Injection-molded and cemented boots cannot be resoled. Wear and tear on the outsole means the end of the boot's life.

Making the Right Choice for Your Jobsite

Your work environment and priorities should guide your decision.

- If your primary focus is maximum durability and long-term value: Choose a boot with Goodyear Welt construction that can be resoled multiple times.

- If your primary focus is lightweight comfort and affordability for less intensive work: A boot with Cement construction is often the most practical choice.

- If your primary focus is a seamless, waterproof bond for consistently wet environments: Look for boots made with Injection-Molded construction.

- If your primary focus is a blend of high flexibility and robust construction: A Stitch-Down boot offers a unique combination often found in premium footwear.

Choosing the right work boot begins with understanding how it's built from the ground up.

Summary Table:

| Construction Method | Key Characteristics | Best For |

|---|---|---|

| Goodyear Welt | Superior durability, can be resoled | Long-term value, rugged environments |

| Cement | Lightweight, flexible, affordable | Light-duty work, immediate comfort |

| Stitch-Down | Flexible, good water resistance | Premium, flexible work boots |

| Injection-Molded | Seamless, waterproof bond | Wet environments, chemical resistance |

Ready to Equip Your Team with the Right Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable Goodyear welt, comfortable cement, flexible stitch-down, and seamless injection-molded constructions.

We can help you select or custom-manufacture the perfect work boot for your specific market demands, ensuring optimal performance, safety, and value for your customers.

Contact our expert team today to discuss your work boot needs and get a quote.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What materials are used in welted boot uppers? Choose the Right Material for Durability & Performance

- What is Thinsulate and what are its benefits? Superior Warmth Without the Bulk

- How do PU boots compare in weight? Achieve 40% Lighter Footwear for Less Fatigue

- Are there vegan or cruelty-free options for women's work boots? Find Safe, Durable Alternatives

- What factors should be considered when choosing the right pair of work boots? A Guide to Safety & Comfort

- Are insulated work boots waterproof? Uncover the Crucial Difference for Your Safety

- Why is it recommended to provide work footwear with slip-resistance and arch support for staff? Ensure Safety on Stone

- Why is the Seamless Lining process essential in diabetic boots? Prevent Ulcers with Friction-Free Protection