Yes, you can temporarily increase the slip resistance of regular shoes, but these methods are best viewed as short-term fixes for low-risk situations. Methods range from abrading the soles with sandpaper to using traction sprays or attachable grips. However, these DIY solutions do not replicate the engineered design and certified safety of true slip-resistant footwear.

The core issue is the difference between adding a temporary layer of grip and possessing a shoe fundamentally designed for safety. While you can make a regular shoe grippier, you cannot easily make it truly slip-resistant in the way certified footwear is.

What Makes a Shoe Truly Slip-Resistant?

Before attempting to modify a regular shoe, it's critical to understand what gives professionally designed footwear its reliable traction. This isn't a single feature, but a system of design elements working together.

The Critical Role of Outsole Material

The material of the outsole is the foundation of grip. True slip-resistant shoes almost always use high-grade soft rubber or polyurethane.

These materials are chosen for their high coefficient of friction, which allows them to maintain a strong hold on surfaces even when wet or oily.

The Importance of Tread Pattern

The pattern carved into the outsole is not for aesthetics. It's a functional design meant to channel liquids away from the bottom of the shoe.

You will often see small, repeating patterns like hexagons or circles. This design creates multiple edges for grip and allows water, oil, and other fluids to disperse quickly, preventing hydroplaning.

The Significance of Tread Depth

A shallow tread is ineffective. Slip-resistant shoes feature deep grooves and channels in the outsole.

This depth ensures that the tread can effectively move liquid away from the contact points, allowing the sole's material to make direct, firm contact with the walking surface.

The Assurance of Certified Standards

Professionally recognized slip-resistant footwear is often tested and certified to meet specific safety benchmarks.

For example, shoes meeting ASTM F3445 standards have been rigorously tested to prove their performance in providing reliable traction, offering an assurance that DIY methods cannot match.

Common Methods to Increase Grip on Regular Shoes

While these techniques fall short of professional standards, they can provide a temporary boost in traction for everyday situations.

Abrasive Techniques

The goal here is to create a rougher, more textured surface on a smooth sole.

Gently rubbing the outsoles with sandpaper can scuff up the surface and create micro-grooves for better grip. Simply wearing new shoes on rough surfaces like concrete or gravel will also naturally achieve this over time.

Additive Solutions

This approach involves applying a substance to the sole to increase its friction.

Specialized traction sprays are the most direct option. In a pinch, a heavy coat of hairspray can provide a very temporary tacky surface. Some people create a mixture of rubber glue and salt to paint onto the sole, though this is less durable.

Attachable Accessories

For severe conditions like ice and snow, the most effective temporary solution is an external device.

Ice grips or cleats that stretch over the shoe provide aggressive metal points that dig into ice, offering a level of traction that a standard sole cannot.

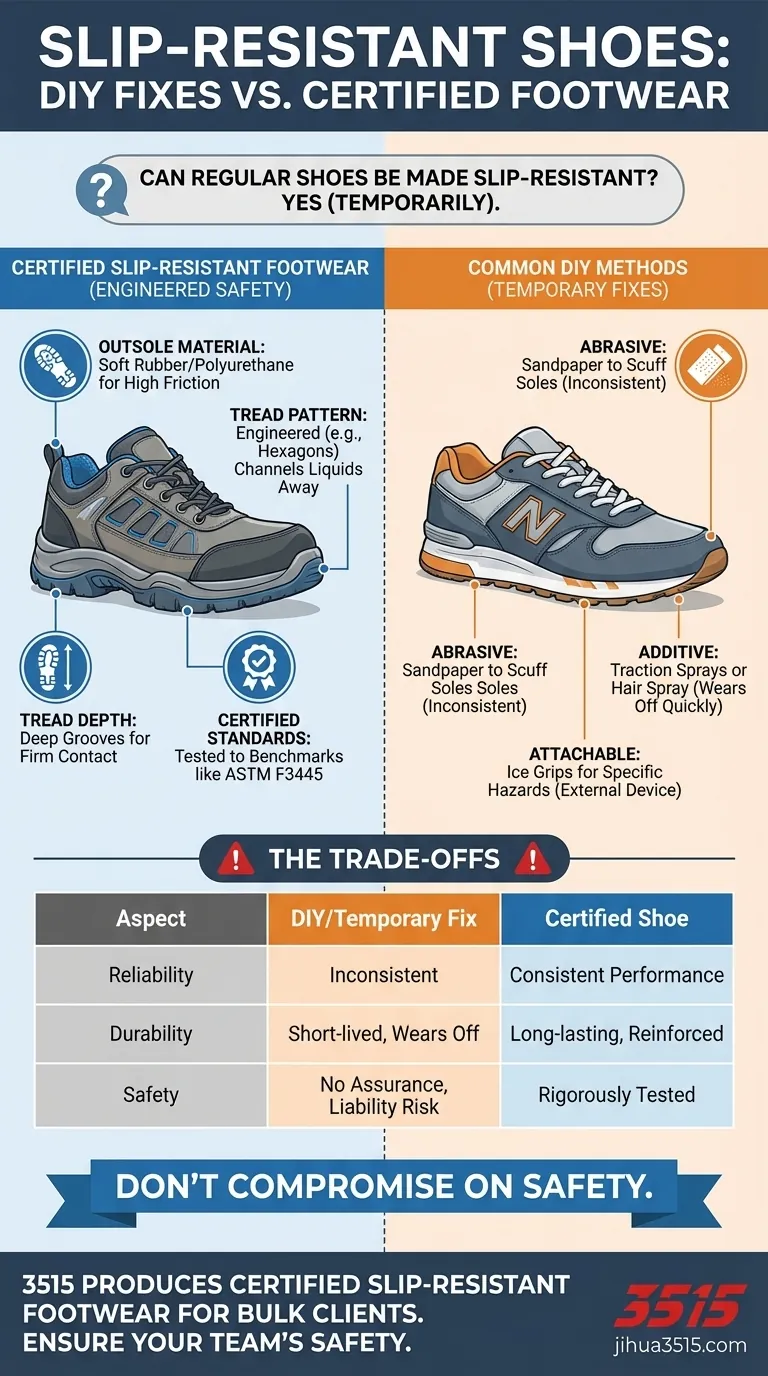

Understanding the Trade-offs: DIY vs. Certified Footwear

Relying on a modified regular shoe carries significant limitations compared to purchasing purpose-built footwear.

Effectiveness and Reliability

DIY methods are inconsistent. Sprays wear off quickly, especially in wet conditions, and abraded soles can wear down and become smooth again.

Certified shoes, by contrast, are designed to provide consistent performance throughout the life of the outsole. Their effectiveness is engineered, not applied.

Durability and Construction

Slip-resistant shoes are built for demanding environments. They often feature reinforced toes, water-resistant uppers, and more durable construction to withstand heavy use.

Regular fashion or athletic shoes are not designed for the same rigors and will break down much faster under similar conditions.

Safety and Liability

In a professional setting, relying on a DIY fix can be a significant liability. Using certified footwear is often a requirement for a reason—it protects both the employee and the employer.

A fall in a workplace due to inadequate footwear is a serious safety failure that certified shoes are designed to prevent.

Making the Right Choice for Your Needs

Your decision should be based entirely on your environment and the level of risk you face.

- If your primary focus is a single, low-risk event: A temporary fix like a traction spray or scuffing the soles with sandpaper may be sufficient for a minor boost in confidence.

- If your primary focus is navigating icy sidewalks: Attachable ice grips are the most effective and reliable non-permanent solution for this specific hazard.

- If your primary focus is workplace safety or frequent exposure to slippery surfaces: Investing in footwear that is officially labeled and certified as slip-resistant is the only responsible choice.

Ultimately, choosing the right approach means understanding that temporary fixes cannot replicate the engineered and tested safety of true slip-resistant footwear.

Summary Table:

| Aspect | DIY/Temporary Fix | Certified Slip-Resistant Shoe |

|---|---|---|

| Outsole Material | Unmodified, often hard rubber | Soft rubber/polyurethane for high friction |

| Tread Pattern | None or ineffective | Engineered (e.g., hexagons) to channel liquids |

| Durability | Short-lived; wears off quickly | Consistent performance for the shoe's lifespan |

| Safety Assurance | No standard or certification | Tested to meet standards like ASTM F3445 |

| Best For | Low-risk, one-off situations | Workplace safety & frequent hazardous exposure |

Don't Compromise on Safety

Temporary fixes are a gamble. For reliable, long-term protection against slips and falls, you need footwear engineered for the job.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed with the critical elements—premium outsole materials, effective tread patterns, and durable construction—that DIY methods can't replicate.

Ensure the safety of your team or customers with footwear built for performance, not just a quick fix.

Contact 3515 today to discuss your slip-resistant footwear needs and get a quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior