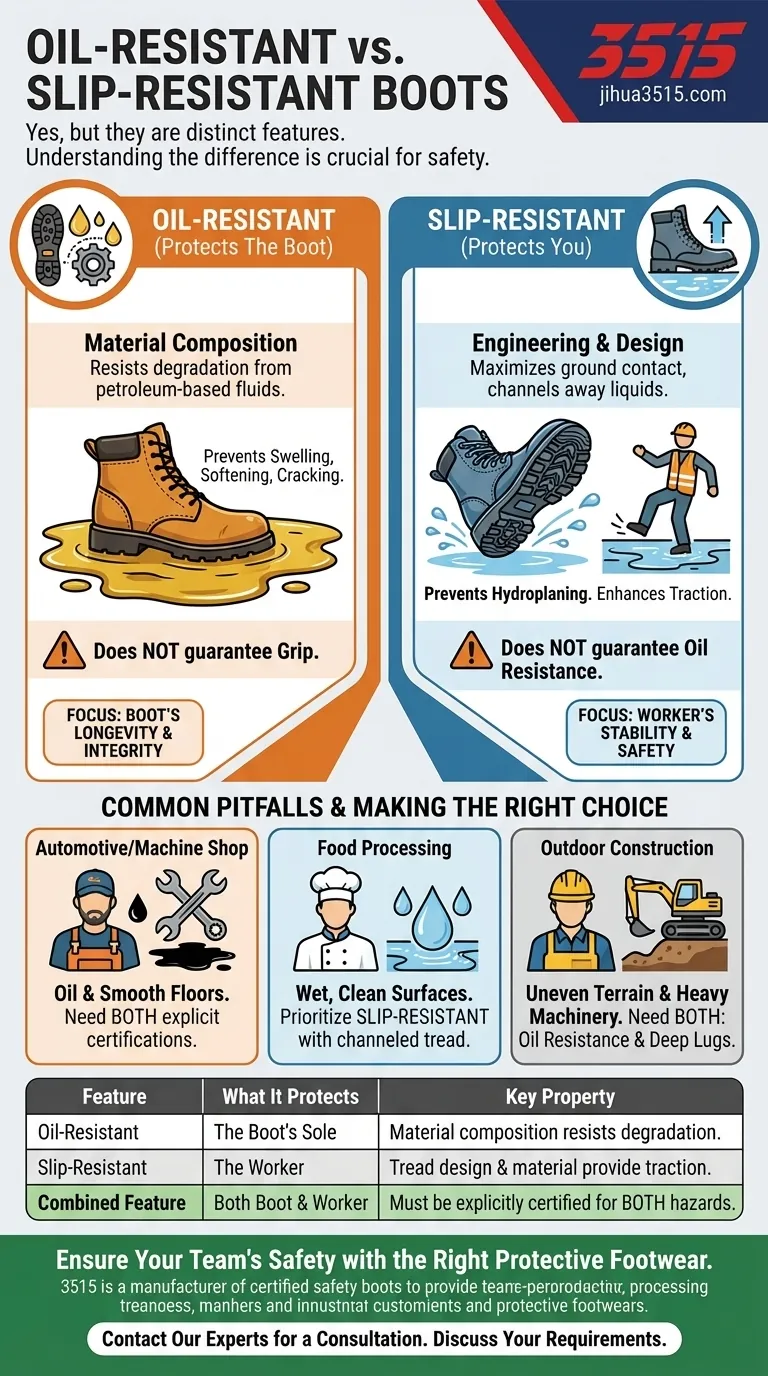

Yes, but it's crucial to understand they are not the same feature. An oil-resistant boot can absolutely be slip-resistant, and in high-hazard industries, the two features are often combined. However, oil resistance and slip resistance are distinct properties that solve different problems. You must verify that a boot is explicitly rated for both if your environment demands it, as one does not automatically guarantee the other.

The core principle is this: Oil resistance protects the boot, while slip resistance protects you. Oil-resistant soles are made of materials that won't degrade when exposed to petroleum, preserving the boot's structural integrity. Slip-resistant soles are engineered with specific tread patterns and materials to provide traction on slick surfaces.

Deconstructing Outsole Safety Features

To make an informed decision, you must understand what each term means from a technical standpoint. They are not interchangeable marketing buzzwords; they are distinct engineering solutions for specific workplace hazards.

What "Oil-Resistant" Actually Means

The oil-resistant rating refers to the material composition of the outsole.

Certain rubber and polymer compounds can swell, soften, or crack when they absorb oils and petroleum-based fluids. An oil-resistant sole is made from a material, like nitrile or specialized polyurethane, that does not degrade from this exposure.

This feature is critical for the boot's longevity and structural integrity. A compromised sole can lead to catastrophic failure, but this rating on its own says nothing about its grip.

The Mechanics of "Slip-Resistant"

The slip-resistant rating is primarily about engineering and design.

This feature is achieved through a combination of a high-friction sole material and a carefully designed tread pattern. The goal is to maximize the contact area with the ground while channeling away liquids that cause hydroplaning.

Tread designs vary based on the intended surface. Fine, intricate patterns work best on smooth, wet, or oily floors by pushing liquid out from under the foot. Deep, aggressive lugs are designed for traction on uneven or loose terrain.

Common Pitfalls and Misconceptions

Trusting that one feature implies another is a common and dangerous mistake. Understanding the nuances is essential for ensuring your personal protective equipment (PPE) is actually protecting you.

The Hazard of Assuming Overlap

A boot can have a durable, oil-resistant sole with a tread pattern completely unsuitable for slippery floors. Likewise, a boot can have an excellent slip-resistant tread made from a material that will quickly break down if exposed to oils in a garage or machine shop.

Never assume. Always look for the specific slip-resistant rating (often marked SRC, SRA, or SRB in safety standards) in addition to the oil-resistant property.

Oil Resistance vs. Broader Chemical Resistance

Be cautious about over-extrapolation. A sole rated as "oil-resistant" is specifically tested against petroleum-based fluids.

This does not guarantee its resistance to other chemicals like industrial solvents, acids, or alkalis. If you work with a variety of chemicals, you must check the boot's specific chemical-resistance ratings against your workplace's safety data sheets.

Fluid Resistance vs. "Waterproof" Construction

The material of an oil-resistant sole is non-porous and will inherently resist water. However, this does not make the entire boot waterproof.

A waterproof rating depends on the boot's overall construction, including sealed seams, gusseted tongues, and waterproof membranes that prevent water from entering through the upper part of the boot.

Making the Right Choice for Your Goal

Your specific work environment must dictate your choice. Analyze the hazards you face daily and select footwear with the precise combination of certified features to mitigate them.

- If your primary focus is working in automotive or machine shops: You need footwear explicitly certified as both oil-resistant and slip-resistant to handle fluid spills on smooth concrete floors.

- If your primary focus is on wet but clean surfaces (e.g., food processing): Prioritize a high-traction, slip-resistant sole with a tread designed to channel water; oil resistance is likely a secondary concern.

- If your primary focus is outdoor construction around heavy machinery: You need both oil resistance to prevent sole degradation and a slip-resistant design with deep lugs for traction on uneven ground.

- If your primary focus is exposure to various chemicals: Look beyond the "oil-resistant" label and find footwear with specific ratings against the chemicals you handle.

By verifying each safety feature independently, you move from hoping your boots are safe to knowing they are.

Summary Table:

| Feature | What It Protects | Key Property |

|---|---|---|

| Oil-Resistant | The Boot's Sole | Material composition that resists degradation from oils and petroleum. |

| Slip-Resistant | The Worker | Tread design and material that provides traction on slick surfaces. |

| Combined Feature | Both Boot and Worker | Must be explicitly certified for both hazards; one does not imply the other. |

Ensure your team's safety with the right protective footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant, slip-resistant, and chemical-resistant footwear designed for high-hazard industries.

Let us help you equip your workforce with boots that meet the precise safety standards of your environment.

Contact our experts today for a consultation to discuss your specific requirements and explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear