Yes, most high-quality Chukka boots can be resoled, particularly those featuring leather soles or stitched construction. While boots with leather soles are almost always serviceable by a professional cobbler, those with rubber soles generally require a specific type of construction to be eligible for repair. If your boots are inexpensive and held together by glue, they likely cannot be resoled.

The possibility of resoling is determined by the construction method, not the style of the boot. If the sole is stitched to the boot, it can likely be replaced; if it is merely glued (cemented), the boot is usually considered disposable.

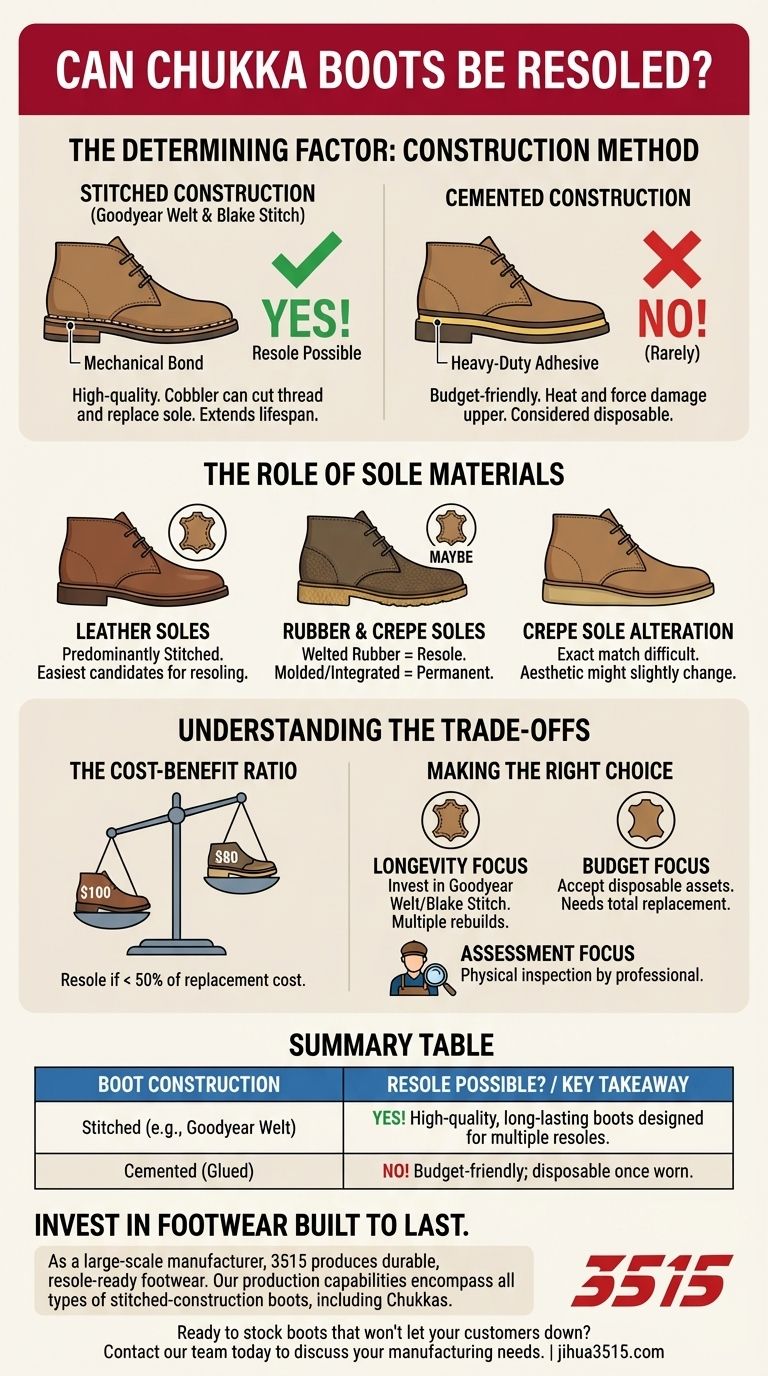

The Determining Factor: Construction Method

To determine if your specific pair of Chukkas is serviceable, you must look at how the bottom of the shoe is attached to the leather upper.

Stitched Construction (Goodyear Welt & Blake Stitch)

High-quality boots utilize a mechanical bond—stitching—to hold the shoe together.

Look for visible stitching around the perimeter of the sole. If these stitches are functional (not just decorative), a cobbler can cut the old thread, remove the worn sole, and stitch on a fresh one. This significantly extends the lifespan of the boot.

Cemented Construction

This is the most common method for budget-friendly footwear. The sole is attached using heavy-duty adhesive rather than thread.

Because the heat and force required to remove a cemented sole often damage the leather upper, these boots are rarely accepted by cobblers for resoling. Once the sole wears out or separates, the boot has reached the end of its life.

The Role of Sole Materials

While construction is the primary factor, the material of the sole itself offers clues regarding repairability.

Leather Soles

Chukkas with leather soles are predominantly built using stitched construction.

Because of this, they are the easiest candidates for resoling. A cobbler can easily sand down or remove the leather layers and rebuild the foundation of the shoe.

Rubber and Crepe Soles

Rubber soles are a "maybe." If the rubber sole is part of a welted (stitched) boot, it can be replaced.

However, many casual Chukkas feature molded rubber units that are glued directly to the boot. Consult a professional to see if your specific rubber sole is integrated or attached; integrated molded soles are generally permanent.

Understanding the Trade-offs

Before rushing to the cobbler, you must objectively evaluate the economics and aesthetics of the repair.

The Cost-Benefit Ratio

Resoling is a skilled trade and comes with a corresponding price tag.

If your Chukkas cost $100 and a full resole costs $80, the repair may not be financially logical. A good rule of thumb is to resole only if the repair costs less than half the price of a replacement pair.

Aesthetic Alterations

Depending on the method used, a resole can slightly alter the profile of the boot.

This is particularly true for Chukkas with crepe soles (a crinkly, natural rubber). Finding an exact match for the original crepe rubber can be difficult, meaning your resoled boots might look slightly different than when they were new.

Making the Right Choice for Your Goal

Whether you are buying new boots or assessing a worn pair, understanding your objective will dictate your next step.

- If your primary focus is longevity: Invest in Chukkas with Goodyear Welted or Blake Stitched construction, as these can be rebuilt multiple times.

- If your primary focus is initial budget: Accept that lower-cost, cemented boots are disposable assets that will need total replacement once worn.

- If your primary focus is assessment: Take the boots to a local cobbler immediately; a physical inspection is the only way to confirm if the internal structure can withstand a repair.

Quality Chukkas are an investment, and proper maintenance allows that investment to pay dividends for years.

Summary Table:

| Boot Construction | Resole Possible? | Key Takeaway |

|---|---|---|

| Stitched (e.g., Goodyear Welt) | Yes | High-quality, long-lasting boots designed for multiple resoles. |

| Cemented (Glued) | No | Budget-friendly boots; once the sole wears out, the boot is disposable. |

Invest in footwear built to last.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, resole-ready footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of stitched-construction boots, including Chukkas, ensuring your customers get long-term value and superior quality.

Ready to stock boots that won't let your customers down? Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the general style consensus for chukka boots? The Ultimate Smart Casual Footwear Guide

- What are the most popular shoe choices for business casual? Loafer, Oxford, or Dress Boot?

- Why are loafers considered a business casual must-have? Achieve Effortless Style and Comfort

- What sole features should be considered when choosing casual shoes? Key Factors for All-Day Comfort

- What happens during the final touches and quality control of cowboy boots? The Final Step to Superior Craftsmanship

- How do chukka boots differ from desert boots? Unlock the Key to Choosing the Right Ankle Boot

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear

- How can Clarks desert boots be styled for a smart-casual office look? Master the Polished, Professional Look